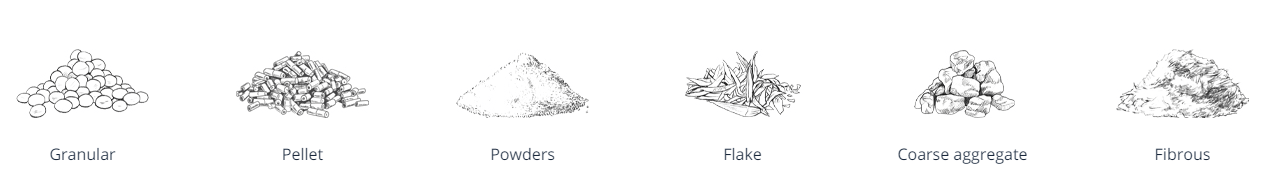

The open mouth bagging systems are specifically designed to efficiently bag free-flowing materials into open-mouth bags ranging from 5 to 50 kg per bag. These systems are particularly suitable for bagging flakes and granules from industries such as Food, Feed, Pet Food, Chemicals, and Minerals.

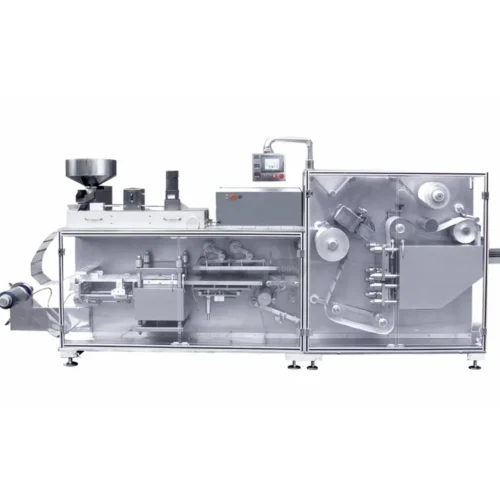

The open mouth bagging equipment comes with modular designs offered in three versions: the compact open-mouth bagging system (FP-200 SERIES up to 200 bags per hour / FP-400 SERIES up to 400 bags per hour), the high-speed open-mouth bagging system (FP-600 SERIES, up to 600 bags per hour), and the high-speed open-mouth bagging system for PE bags (FP-600 FS SERIES, up to 600 bags per hour). These units can be equipped with either gross or net weighing systems to ensure optimal system performance.

Key Features of the Open Mouth Bagger include:

- Automatic adjustments for quick product and bag changeovers

- Total bag top control

- Optimised dust control

- PLC controlled with user-friendly human machine interfaces (HMI)

- Easy to clean and maintain configurations

- Compact design suitable for restricted packaging rooms

- Fully integrated gross or net weighing systems

Machine details encompass a variety of features such as all common types of bag closing devices, bag marking systems for empty or filled bags, product de-aeration, remote control panel, bag turning, closed bag (top or bottom first), and a full stainless steel design.

Applications for the Open Mouth Bagging Machine focus on packing powders with good fluidity like starch, flour, tea powder, and salt. It can also be used for packaging items such as washing powder, rice, flour, beans, pet food, PVC, and fertilizers.

The machine can handle various bag types including paper bags, paper-plastic composite bags, PE bags, woven bags, and aluminum foil bags. It offers a range of technical parameters such as packaging speed, power consumption, and equipment size to suit different production needs.

The working process involves several steps including pre-placing empty bags, bag opening and supplying, material filling, and heat sealing for efficient and automated operation. The factory gallery showcases a glimpse of the manufacturing process and the machinery involved.

This rewritten content aims to consolidate and present the information provided in the original text in a more organized and concise manner. Let me know if you need further modifications or additional details.