List Technical Parameters of “honey packaging machine”

Honey packaging machines are essential in the packaging of honey in sealed packets that offer quality and safety to the consumer. Technical parameters of a honey packaging machine may vary depending on the specific machine model, design, and manufacturer. However, some of the most critical technical parameters to look out for include the following:

1. Packaging speed: Honey packaging machines should have adjustable packaging speeds to suit the required output rates.

2. Packaging material: These machines should handle different packaging materials such as PET, LDPE, and laminated films.

3. Accuracy and consistency: Honey packaging machines must possess the ability to dispense accurate quantities of honey into each packet consistently.

4. Seal strength: Honey packaging machines should seal packets tightly to prevent any leakages or contamination.

5. Control systems: An efficient honey packaging machine should have programmable control systems with a touchscreen panel, which can be set to work automatically.

6. Safety features: A honey packaging machine should be fitted with necessary safety features such as warning systems, automatic shut off, and emergency stops to ensure that the machine does not pose a risk to users.

7. Product compatibility: Honey packaging machines should be compatible with the viscosity and texture of different kinds of honey and not affect the quality or integrity of the product.

8. Maintenance and cleaning: Honey packaging machines should be easy to clean and maintain, with easily removable components and quick connectivity for repairs and replacements.

Overall, choosing the right honey packaging machine would ensure that you can efficiently and safely package your honey with minimal human input while at the same time, guaranteeing the integrity and quality of the honey.

List Product features of “honey packaging machine”

Honey packaging machines are specialized machines designed to pack honey into bottles, jars, or other packaging containers. These machines are commonly used in the food processing industry to improve efficiency and pack honey into containers. There are several types of honey packaging machines available, and their features can vary depending on the manufacturer and the model.

1. Automatic packaging: Honey packaging machine features automatic packaging that is designed to improve the efficiency of packing honey into containers.

2. Versatility: Honey packaging machines can be used to pack different types of honey into various containers, including glass jars, plastic bottles, and sachets.

3. High accuracy: These machines offer high-level accuracy to ensure that the package has the correct measurement. They can control the filling levels with impressive accuracy, ensuring consistent density.

4. Customizable: Honey packaging machines can be customized to suit the specific packaging needs of a particular production line.

5. User-friendly: Honey packaging machines are designed to be easy to operate, even for inexperienced operators. These machines are built using state-of-the-art technology, making them user-friendly and efficient.

6. Easy to clean: The machines are made of stainless steel, which makes them easy to clean and hygienic. This feature ensures that the product is free of contaminants that can affect the quality of the honey.

7. Controlled Packaging speed: Honey packaging machines are built with a variable speed control feature. The feature allows the operator to control the packing speed for improved efficiency.

8. Minimal maintenance: The machines have a simple design that requires minimal maintenance. They have a low need for technical support, ensuring that the production process is not interrupted.

9. Energy-efficient: Honey packaging machines are designed to be energy-efficient, reducing utility costs for the production process.

In conclusion, honey packaging machines are essential tools in the food processing industry that help to improve efficiency and consistency. The features specified above make the machine one of the most convenient and valuable tools for honey processing businesses.

List Application of “honey packaging machine”

Honey packaging machines are essential equipment in the food packaging industry, specifically in the honey packaging sector. They provide an efficient and faster way of packing honey into jars, sachets, and bottles. Here are some applications of honey packaging machines.

1. Production Efficiency: The use of honey packaging machines increases the production efficiency and reduces the time spent manually filling, capping, and labeling honey jars. This results in lesser production costs, and the risk of contamination is reduced.

2. Flexibility: Most honey packaging machines are versatile, which means they can be used to pack honey in various sizes of bottles, jars, and sachets. By adjusting the machine settings, the operator can package the right quantity of honey required by the customer.

3. Quality Control: Honey packaging machines help to maintain quality control by ensuring that the packaging is done correctly. The weight of each package is measured accurately, and the volume of honey in the package is consistent throughout the production run.

4. Sanitation: Honey packaging machines are built to adhere to strict hygiene standards, which means that the likelihood of contamination is greatly reduced. This is important because honey is vulnerable to contamination, which could render it unfit for human consumption.

5. Cost-Effective: Honey packaging machines are affordable, and they save packaging costs because the operator can package exactly the quantity required by the customer. Additionally, the machine requires minimal maintenance, which means that the production costs are further reduced.

In conclusion, honey packaging machines offer a lot of benefits to honey packers. They increase production efficiency, quality control, sanitation, and cost-effectiveness. With their versatility, packers can package honey in various bottle sizes, jars, and sachets, meeting the specific needs of their customers. They are a valuable addition to any honey packaging enterprise.

List Various Types of “honey packaging machine”

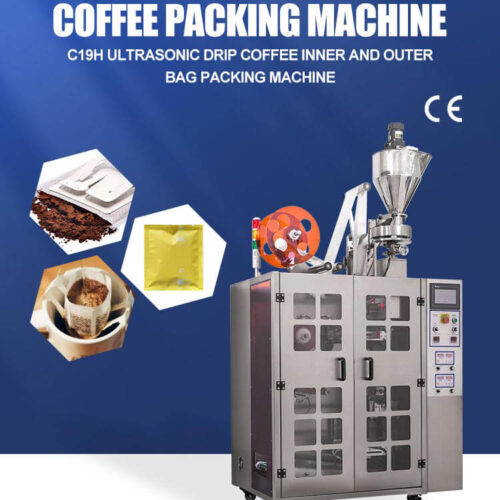

1. Vertical Form Fill Seal Machines: These machines are used to package honey in pouches. They can be adjusted to produce different pouch sizes, and they have the ability to fill and seal multiple pouches at the same time, significantly increasing production rates.

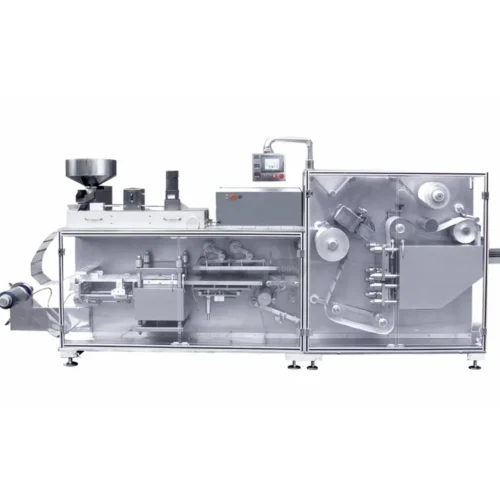

2. Jar Filling Machines: These machines are used to fill jars with honey. They can handle various types of jars, including PET, glass, and plastic. They come equipped with a piston filling system, which can accurately fill jars to a specified volume.

3. Automatic Honey Stick Packing Machines: These machines are designed to fill and seal individual honey sticks automatically. The machine manufactures them according to the necessary weight and packaging preference. They can produce up to 600 sticks per minute.

4. Bottle Filling Machines: These semi-automatic machines are used to fill bottles with honey. They are equipped with a piston filling system and can fill up to 1000 bottles per hour.

5. Flow Wrapping Machines: These machines are used to package honey in flow packets. The honey is fed into the machine, and it is wrapped in a transparent film. It has the ability to produce different packet sizes, and it can run at speeds of up to 300 packets per minute.

6. Automatic Sachet Honey Packing Machines: These machines are designed to fill and seal sachets of honey. They are versatile and can be adjusted to produce various sachet sizes and packaging materials. They can produce up to 600 sachets per minute.

7. Preformed Pouch Fill and Seal Machines: These machines are designed to fill and seal pre-formed pouches with honey. They use a weighing system to accurately fill the pouch with the correct amount of honey.

In conclusion, the honey packaging machine market offers a range of options for small and large-scale operations. The above machines are just a few examples of the variety of packaging machines available; their specifications and features remain dependent on the user’s product, production requirements, and budget.

List The Process of “honey packaging machine”

Honey packaging machines are designed to package honey in bottles, jars, or any other container. The process involves different steps that ensure the honey is packaged efficiently and hygienically. Here are the steps involved in the honey packaging machine:

1. Honey Collection: The first step involved in honey packaging is the collection of honey. The honey is collected from bees and processed to remove any impurities and ensure it is of high quality.

2. Filling the Honey: Once the honey is pure, it is stored in a tank or silo from where it is pumped into the honey filling machine. The filling process is automated, and it involves the use of a piston, peristaltic pump, or gear pump to fill the honey into bottles or jars.

3. Sealing the Honey Containers: After filling the honey, the next step is to seal the containers. The sealing process involves the use of a capper, which seals the bottles’ lids, ensuring that the honey stays fresh and doesn’t leak.

4. Labeling the Honey Containers: The honey containers’ labeling is an essential aspect of the packaging process. The labeling process involves the use of a labeling machine to print labels and stick them on the containers. This step ensures that the customers know what they are buying and the honey’s source.

5. Packing the Honey Containers: The final step in the honey packaging process is packing the honey containers in boxes for storage or transportation. The honey packages are packed into boxes of different sizes, and each box is marked with the product’s details.

In conclusion, the honey packaging machine follows a strict and efficient process to ensure that the honey is packaged under high hygienic conditions. The process involves honey collection, filling, sealing, labeling, and packing the containers for storage or transportation.

How to use “honey packaging machine”

Honey packaging machine is a specialized equipment that is designed to help package honey for commercial purposes. It is a highly efficient machine that can package honey into various containers, such as glass jars, plastic containers, and squeeze bottles. The machine is easy to operate and requires minimal maintenance. Here are the steps to follow in using a honey packaging machine:

1. Prepare the Honey: The first step in using a honey packaging machine is to prepare the honey. This involves filtering the honey to remove any impurities and ensuring that the honey is of the desired consistency.

2. Set up the Machine: Once the honey is prepared, set up the machine by assembling the various components and ensuring that they are in working order. Check that the conveyor belt, filling chamber, and dispenser are all in good condition.

3. Adjust the Settings: Depending on the type of container being used, adjust the settings of the honey packaging machine. This includes adjusting the fill volume and setting the speed of the conveyor belt.

4. Start the Machine: After adjusting the settings, start the machine by powering it on. The conveyer belt will start running, and the filling chamber will begin to dispense the honey into the containers.

5. Monitor the Process: Keep an eye on the honey packaging process to ensure that everything is running smoothly. Check that the containers are being filled correctly, and that there are no leaks or spills.

6. Label and Package: Once the containers are filled, label them with the appropriate information, including the type of honey, the date, and the batch number. Then, package the containers for shipping or storage.

In conclusion, using a honey packaging machine is a straightforward process that requires a few simple steps. By following the above steps, one can efficiently package honey into different containers, saving time and money in the process.

List Properties of “honey packaging machine”

1. Capacity: Honey packaging machines are available in various capacities, starting from a few hundred packs per hour to several thousand packs per hour.

2. Material: The honey packaging machine is typically constructed from high-quality stainless steel, making it sturdy, rust-resistant, and easy to clean.

3. Filling Range: Honey packaging machines are capable of filling different volumes of honey into packages ranging from 5g to 1000g.

4. Filling Accuracy: Honey packing machines are designed to provide consistent and accurate filling using a volumetric or weight filling method.

5. Package Sizes: The honey packaging machine can handle various package sizes and shapes, with the most common being sachets, pouches, and bottles.

6. Additional Features: Some honey packaging machines come with additional features such as date coding, sealing, and labeling systems, to ensure that the packages are properly sealed and labeled.

7. Energy Efficiency: Honey packaging machines are energy-efficient, with most models using less energy and reducing the carbon footprint.

8. User-Friendly: The honey packaging machine comes equipped with an intuitive user interface that is easy to operate, reducing the risk of operator error.

9. Maintenance: Honey packaging machines are designed for easy maintenance, with most components easily accessible, and hence, effortless to clean.

10. Compliance: Honey packaging machines adhere to industry regulations, including safety, health, and quality standards.

List “honey packaging machine” FAQ

1. What is a honey packaging machine?

A honey packaging machine is a type of machinery designed to pack honey into containers, usually jars or bottles, for commercial distribution and consumption.

2. What are the types of honey packaging machines?

There are several types of honey packaging machines, including semi-automatic, automatic, and fully automatic machines. The main difference between them is the level of automation and speed, with the fully automatic machine being the fastest and highest in terms of production volume.

3. How does a honey packaging machine work?

The honey packaging machine works by feeding honey into a hopper, which feeds the machine’s conveyor belt. The machine automatically fills the containers, seals them, and labels them, if necessary.

4. Can a honey packaging machine pack different container sizes?

Yes, honey packaging machines are designed to accommodate different container sizes and shapes, allowing for versatility in packing. The settings can be adjusted to cater to a range of container sizes by changing the mold for the machine.

5. What is the production capacity of a honey packaging machine?

The production capacity of a honey packaging machine depends on the model and type of machine. The semi-automatic machine can produce up to 120 jars per hour, while the fully automatic machine can produce up to 1000 jars per hour.

6. Can a honey packaging machine handle different types of honey?

Yes, honey packaging machines can handle different types of honey, including raw honey, creamed honey, and liquid honey, by adjusting the heating and cooling settings to ensure the honey is appropriate for packaging.

7. What is the maintenance cost of a honey packaging machine?

The maintenance cost of a honey packaging machine depends on the type of machine and the level of use. Regular maintenance should be carried out, including cleaning, lubricating, and replacing worn parts, to ensure optimal performance and longevity of the machinery.

In conclusion, a honey packaging machine is an important machine in the food processing industry that plays a crucial role in the packaging and commercial distribution of honey in varying quantities and the desired packaging format.