List Technical Parameters of “ice pop filling sealing machine”

Ice pop filling sealing machine is a versatile machine used in the process of filling and sealing ice pops. The machine can handle a wide range of materials, including fruit juices, yogurt, ice cream, and mixtures. The ice pop filling sealing machine is ideal for use in small and medium-sized enterprises that require efficient, reliable, and consistent production of ice pops.

The technical parameters of the ice pop filling sealing machine include the machine’s size, weight, power supply, production capacity, and filling accuracy. Firstly, the machine’s size and weight are critical factors that determine where and how the machine can be installed. The machine’s dimensions and weight also determine the amount of space that the machine occupies, making it easy to integrate into existing production lines.

Secondly, the ice pop filling sealing machine requires a stable power supply to function optimally. The power requirement of the machine ranges from 220 volts to 380 volts, depending on the model and configuration. The machine’s power consumption is also a critical parameter that should be considered when choosing the right model for the production line.

Thirdly, the production capacity of the ice pop filling sealing machine is a critical parameter that determines the machine’s output per hour. The machine’s capacity ranges from 1500 to 3000 pieces per hour, depending on the model and configuration. Additionally, the machine’s filling accuracy guarantees the consistent and uniform filling of the ice pop.

Finally, the ice pop filling sealing machine’s operation principle is also an essential technical parameter. The machine operates using a set of synchronized processes: material loading, filling, sealing, and cutting. The machine’s operation principle ensures that the production process is efficient, reliable, and consistent, saving time and minimising wastage.

In conclusion, the technical parameters of the ice pop filling sealing machine are crucial for achieving efficient and reliable production of ice pops. When selecting the right model for your production line, it is essential to consider the machine’s size, power supply, production capacity, filling accuracy, and operational principle to ensure maximum productivity and profitability.

List Product features of “ice pop filling sealing machine”

The ice pop filling sealing machine is a reliable and efficient machine designed for filling and sealing ice pops. It is equipped with several features that make it ideal for use in ice pop production. Some of the product features of the ice pop filling sealing machine include:

1. High-Speed Production: The machine is designed for high-speed production and can fill and seal up to 6000 units per hour. This makes it ideal for large-scale ice pop production.

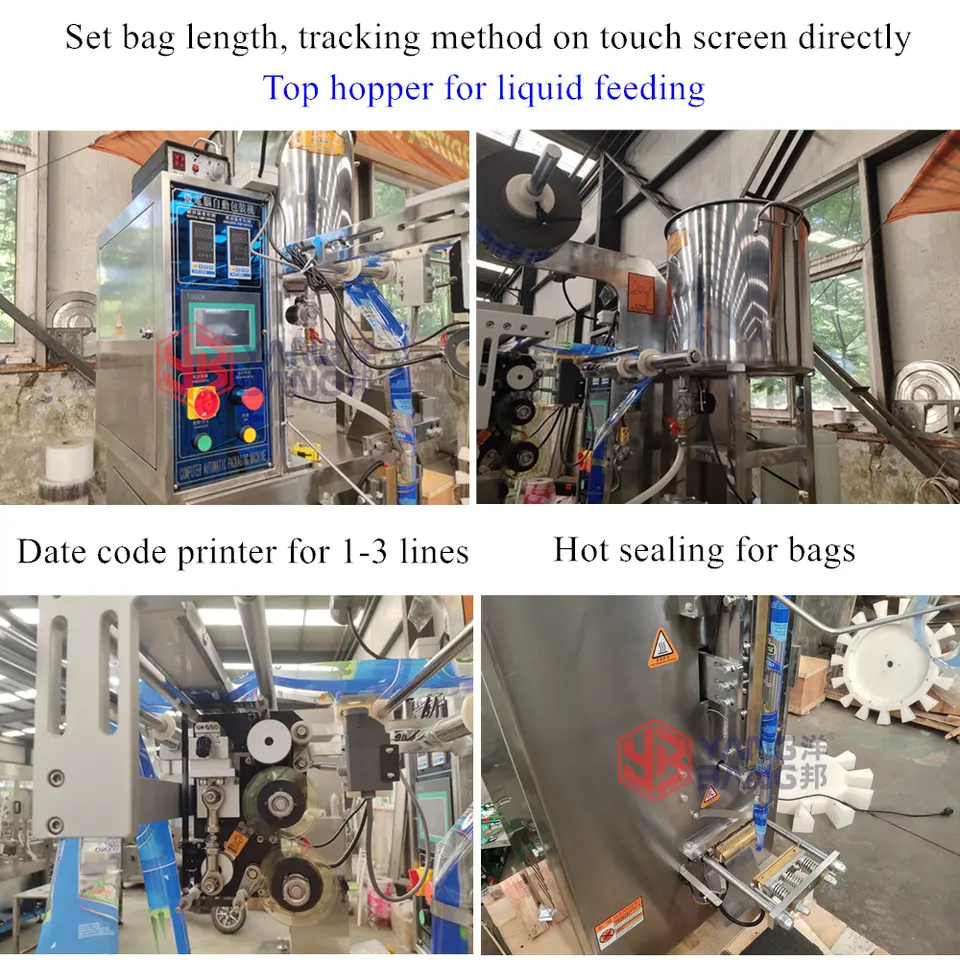

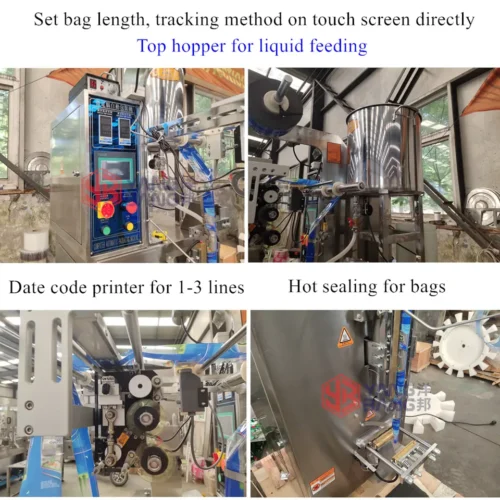

2. Automatic Control: The machine is equipped with an automatic control system that ensures accurate filling and sealing of ice pops. The control system is programmable and can be set to meet the specific needs of the user.

3. Easy to Clean: The machine is designed to be easy to clean, with all the parts accessible for cleaning. This makes maintenance and cleaning of the machine easy and quick.

4. Efficient Cooling System: The ice pop filling sealing machine is equipped with an efficient cooling system that keeps the machine and the ice pops at the ideal temperature for production. The cooling system ensures that the ice pops are frozen quickly and efficiently.

5. Multiple Popsicle Molds: The machine comes with multiple popsicle molds of different shapes and sizes. These molds can be easily changed to produce different types of ice pops.

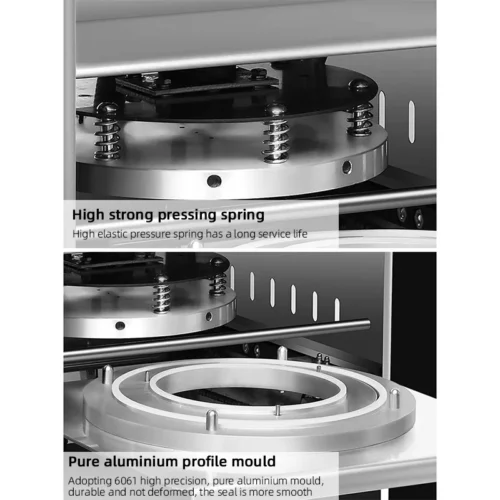

6. Durable Construction: The machine is made from high-quality materials that are durable and long-lasting. This ensures that the machine will last a long time and perform reliably.

7. User-friendly Interface: The machine has a user-friendly interface that is easy to understand and use. It comes with a touch screen that allows users to adjust settings and monitor the production process.

8. Customizable: The ice pop filling sealing machine can be customized to meet the specific needs of the user. This includes adding additional features or modifying the machine to fit different types of ice pops.

In conclusion, the ice pop filling sealing machine is a versatile, efficient, and reliable machine that comes equipped with several features designed to make ice pop production easy and efficient. Its high-speed production capacity, automatic control system, easy-to-clean design, efficient cooling system, and customizable features make it an ideal machine for ice pop manufacturers.

List Application of “ice pop filling sealing machine”

An ice pop filling and sealing machine is a device that is used to fill and seal ice pops or ice lollies at a commercial level. These machines are designed to automate the entire process of filling and sealing ice pops, which increases the efficiency and speed of the production line. Here are some of the applications of an ice pop filling sealing machine.

1. Food and Beverage Industry – This machine is commonly used in the food and beverage industry to manufacture ice pops on a large scale. This includes using it in ice cream parlors, ice lolly factories, and beverage companies that manufacture frozen drinks.

2. In-Flight Services – Ice pops are a popular snack that is served during long flights. An ice pop filling sealing machine is therefore used by airlines to produce and package ice pops for their in-flight services.

3. Food Trucks – An ice pop filling sealing machine is an ideal device for food trucks that specialize in producing frozen treats. This allows food trucks to produce ice pops quickly and efficiently, which increases their sales volume and customer satisfaction.

4. Supermarkets – Large supermarkets that have in-house food production facilities use ice pop filling sealing machines for producing ice pops for their customers. This helps ensure that the ice pops meet the desired hygiene and quality standards.

5. Events and Parties – Ice pop filling sealing machines can be used at events and parties where frozen treats are being served. The machine provides a fast and easy way to produce customized ice pops that can be personalized to match the theme of the event or party.

In summary, an ice pop filling sealing machine is a versatile device that has a wide range of applications in the food and beverage industry. Its ability to produce ice pops on a large scale and customize them makes it an essential device for many businesses.

List Various Types of “ice pop filling sealing machine”

1. Fully-Automatic Ice Pop Filling Sealing Machine: This machine is designed to carry out the entire ice pop filling and sealing process on its own. It can handle large volumes, and its operation is highly intuitive.

2. Semi-Automatic Ice Pop Filling Sealing Machine: This machine requires some level of human input, such as placing the ice pops in their slots, and starting the operation. However, it still automates the filling and sealing process.

3. Rotary Ice Pop Filling Sealing Machine: This machine has a rotary system that moves the ice pops through the filling and sealing process. It is highly efficient and can handle large volumes of ice pops.

4. Pneumatic Ice Pop Filling Sealing Machine: This machine uses compressed air to move the ice pops through the filling and sealing process. It is ideal for small to medium-sized ice pop production lines.

5. Manual Ice Pop Filling Sealing Machine: This machine requires manual input throughout the entire process. It is best suited for small scale ice pop production, or for use in low-tech settings.

6. Stick Ice Pop Filling Sealing Machine: This machine is specifically designed for the production of stick ice pops. It can handle different stick sizes and shapes, and usually operates in a semi-automatic or fully-automatic mode.

7. Cup Ice Pop Filling Sealing Machine: This machine is suitable for the production of cup ice pops. It can handle different cup sizes and shapes, and is usually a fully-automatic machine.

8. Multi-Lane Ice Pop Filling Sealing Machine: This type of machine has multiple lanes that can produce and fill several ice pops at once. It is ideal for high volume production lines.

In summary, there are various types of ice pop filling sealing machines available, each with unique features and capabilities suited for specific production needs.

List The Process of “ice pop filling sealing machine”

The process of an ice pop filling sealing machine involves several steps:

1. Preparation of the machine: The machine should be checked to ensure that it is in good condition. The necessary tools and equipment should also be assembled before starting the process.

2. Filling the ice pops: The machine should then be filled with the ice pop mixture. The mixture should be the right consistency to ensure the ice pops have a good texture. A filling nozzle connected to the machine is used to fill the molds with the mixture.

3. Sealing the ice pops: After filling the molds, the machine seals the molds with the ice pop mixture. It ensures that no leaks occur during the freezing process.

4. Freezing the ice pops: After the sealing process is complete, the molds are taken to a freezer to freeze the ice pops thoroughly. A faster freezing process is necessary to ensure that the ice pops are frozen uniformly.

5. Demolding: Once the ice pops are frozen, the molds are removed from the freezer. The ice pops are then demolded by opening the molds and removing the ice pops.

6. Packaging: After demolding, the ice pops are packaged according to the manufacturer’s specifications. The packaging process involves labeling, wrapping, and placing the ice pops in boxes or bags.

7. Distribution: The final stage of the ice pop filling sealing machine process involves the distribution of the ice pops. The ice pops are shipped to wholesalers, retailers, or directly to consumers depending on the manufacturer’s preference.

In conclusion, the ice pop filling sealing machine process involves several steps that must be carefully followed to produce high-quality ice pops. It is an essential process that ensures that the ice pops are safe, hygienic, and have a long shelf life.

How to use “ice pop filling sealing machine”

The ice pop filling sealing machine is a versatile machine used to fill and seal ice pop bags. The machine is easy to operate and requires no special skills to use. Here are the steps on how to use the ice pop filling sealing machine.

Step 1: Preparing the Machine

The first step is to prepare the machine for use. This involves plugging in the machine, setting the temperature, and allowing the machine to warm up. The machine has a digital temperature controller that allows you to adjust the temperature to suit your needs.

Step 2: Prepare the Ice Pop Bags

The second step is to prepare the ice pop bags for filling. The ice pop bags come in different sizes, shapes, and colors, and it is important to choose the right size and shape for the machine. Once you have the right bags, you should open them up and place them on the filling tray.

Step 3: Filling the Ice Pop Bags

The third step is to fill the ice pop bags. The machine has a filling pump that you can use to fill the ice pop bags with your desired liquid such as juice or flavored water. You can adjust the filling volume to suit the bag size.

Step 4: Sealing the Ice Pop Bags

The fourth step is to seal the ice pop bags. The machine has a sealing wand that you can use to seal the top of the ice pop bags. You should hold the bag tightly to ensure that it is sealed correctly.

Step 5: Cutting the Ice Pop Bags

The fifth step is to cut the sealed ice pop bags. The machine comes with a cutting mechanism that you can use to cut the sealed ice pop bags. You should be careful not to cut too close to the seal or too far away.

In conclusion, the ice pop filling sealing machine is easy to use and requires no special skills to operate. It is important to read the machine manual carefully to ensure that you use the machine correctly and safely. The machine is suitable for small-scale ice pop production or for home use.

List Properties of “ice pop filling sealing machine”

The ice pop filling sealing machine is a piece of automated equipment used by manufacturers to package ice pops in a fast and efficient manner. It is a specialized machine that fills, seals, and labels ice pops with ease. Here are some of the properties of the ice pop filling sealing machine:

1. Automated Operation: The ice pop filling sealing machine is fully automated, which means that the entire process is conducted without human intervention. The machine is designed to detect and correct any errors during the filling and sealing process.

2. High Efficiency: The ice pop filling sealing machine is capable of filling and sealing up to 6000 ice pops per hour. This high level of efficiency helps manufacturers to speed up their production process and produce large quantities of ice pops in a short amount of time.

3. Versatility: The ice pop filling sealing machine can be used to fill and seal different types of ice pops, including round, square, and rectangular shapes.

4. Easy to Operate: The ice pop filling sealing machine is easy to operate and requires minimal training. The machine is equipped with a user-friendly interface that enables the operator to set the filling and sealing parameters easily.

5. Hygienic Design: The ice pop filling sealing machine is designed with hygiene in mind. It is made of materials that are easy to clean and sanitize, which helps to prevent contamination.

6. High Accuracy: The ice pop filling sealing machine is designed to fill and seal ice pops with a high level of accuracy. This ensures that the ice pops are of the same weight and size.

7. Cost-Effective: The ice pop filling sealing machine is a cost-effective investment for manufacturers. It helps to reduce labor costs, increase production efficiency, and prevent wastage.

In conclusion, the ice pop filling sealing machine is a specialized and efficient piece of equipment that is designed to help manufacturers produce ice pops in a fast and efficient manner. Its versatility, hygienic design, ease of use, and high efficiency make it an ideal investment for ice pop manufacturers looking to boost their production capabilities.

List “ice pop filling sealing machine” FAQ

1. What is an ice pop filling sealing machine?

An ice pop filling sealing machine is a device that is used to fill and seal ice pops. It is designed to make the process of filling and sealing ice pops faster and more efficient.

2. How does an ice pop filling sealing machine work?

An ice pop filling sealing machine works by filling ice pop molds with liquid using a nozzle and then sealing the molds using heat.

3. What types of ice pops can be made using an ice pop filling sealing machine?

An ice pop filling sealing machine can be used to make a variety of ice pops, including fruit juices, smoothies, and frozen yogurt pops.

4. What is the capacity of an ice pop filling sealing machine?

The capacity of an ice pop filling sealing machine varies from model to model. Some machines can fill and seal hundreds of ice pops per hour, while others are designed for smaller production runs.

5. What are the features of an ice pop filling sealing machine?

The features of an ice pop filling sealing machine may include automatic filling, automatic sealing, adjustable nozzle height, and the ability to fill multiple molds at once.

6. What are the benefits of using an ice pop filling sealing machine?

The benefits of using an ice pop filling sealing machine include increased production efficiency, reduced labor costs, and consistent product quality.

7. What types of industries use ice pop filling sealing machines?

Industries that use ice pop filling sealing machines include food and beverage production, ice cream production, and snack production.

8. How do you maintain an ice pop filling sealing machine?

To maintain an ice pop filling sealing machine, you should clean it regularly and follow the manufacturer’s recommended maintenance schedule.

9. How much does an ice pop filling sealing machine cost?

The cost of an ice pop filling sealing machine varies depending on the model and features. Prices can range from a few thousand dollars to tens of thousands of dollars.

10. Where can I purchase an ice pop filling sealing machine?

Ice pop filling sealing machines can be purchased from manufacturers, distributors, and online retailers. Researching and comparing prices and features of different machines is recommended before making a purchase.