List Technical Parameters of "label application machine"

A label application machine is a type of equipment used to apply labels onto various products or packaging materials in a consistent and efficient manner. Some of the important technical parameters associated with a label application machine include:

1. Speed: The speed at which the machine can apply labels onto products, typically measured in labels per minute.

2. Labeling accuracy: The ability of the machine to apply labels with precision and consistency, ensuring that they are aligned correctly on the product.

3. Label size range: The range of label sizes that the machine can accommodate and apply onto products.

4. Conveyor speed: The speed at which the conveyor belt on the machine moves, carrying products through the labeling process.

5. Label type: The types of labels that the machine is compatible with, such as self-adhesive labels, wrap-around labels, or shrink sleeve labels.

6. Integration capabilities: The ability of the machine to integrate with other packaging equipment, such as filling machines or capping machines, for a seamless production process.

7. Machine dimensions: The physical dimensions of the machine, including its height, width, and length, to determine the space required for installation.

8. Power requirements: The electrical power needed to operate the machine, including voltage and frequency specifications.

Overall, a label application machine plays a crucial role in the packaging process by automating the labeling of products and ensuring consistency in the labeling process. The machine’s technical parameters are important considerations when selecting the right equipment for a specific production line.

List Product features of "label application machine"

A label application machine is a versatile piece of equipment used in various industries to accurately apply labels onto products or packaging. Some key features of a label application machine include:

1. Automatic label feeding: The machine is equipped with a system that automatically feeds labels onto the product, ensuring a consistent and efficient labeling process.

2. Variable speed control: Users can adjust the speed at which labels are applied, allowing for customization based on the size and shape of the products being labeled.

3. Precision labeling: The machine is designed to apply labels with a high degree of accuracy, reducing the chances of misalignment or errors in labeling.

4. Easy setup and operation: Label application machines are user-friendly and can be set up quickly, minimizing downtime and improving productivity.

5. Versatility: These machines can handle a wide range of label sizes and shapes, making them suitable for various products and packaging types.

6. Durable construction: Label application machines are typically built to withstand the rigors of industrial use, ensuring long-term reliability and performance.

7. Multiple labeling options: Some machines offer the flexibility to apply front, back, top, or wrap-around labels, allowing for versatile labeling solutions.

8. Integration capabilities: Label application machines can be integrated with other packaging equipment such as conveyors and printers for a seamless labeling process.

In conclusion, a label application machine is a valuable asset for businesses looking to streamline their labeling processes and ensure product consistency and quality. This equipment offers a range of features that make it a versatile and efficient solution for various labeling needs.

List Application of "label application machine"

Label application machines are commonly used in various industries for a variety of purposes. Some of the common applications include:

1. Food and Beverage Industry: Label application machines are used to apply product labels on food and beverage packaging. This ensures that the correct information such as ingredients, nutritional facts, and expiration dates are clearly displayed on the packaging.

2. Pharmaceutical Industry: Label application machines are used to accurately apply labels on medication packaging. This is crucial for ensuring that the right dosage information, warnings, and other important details are visible to the consumer.

3. Cosmetics Industry: Label application machines are used to apply labels on cosmetic products such as bottles, jars, and tubes. This helps in branding and providing important information to the consumers about the product ingredients and usage instructions.

4. Manufacturing Industry: Label application machines are used for product identification and tracking in the manufacturing process. They can be used to apply labels on products, parts, and packaging for inventory management and quality control purposes.

5. Retail Industry: Label application machines are used in retail stores for labeling merchandise with price tags, barcodes, and product information. This helps in the efficient management of inventory and enhances the shopping experience for customers.

Overall, label application machines play a crucial role in ensuring accurate and efficient labeling in various industries, helping businesses streamline their operations and meet regulatory requirements.

List Various Types of "label application machine"

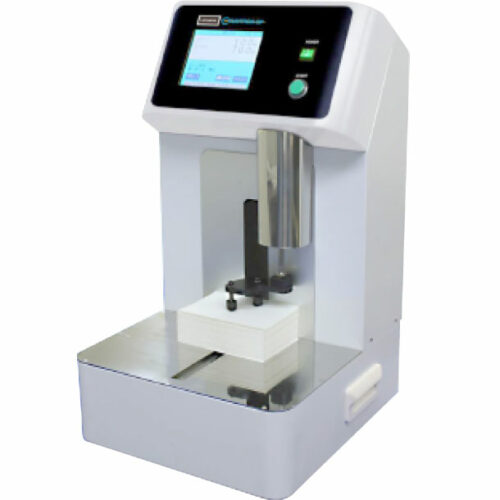

1. Automatic labeling machine: This type of machine is equipped with sensors and computerized controls to apply labels onto products accurately and efficiently. It can handle a wide range of label sizes and shapes, making it ideal for high-volume production environments.

2. Manual label applicator: This type of machine requires an operator to feed the labels and products into the machine manually. While it is less automated than automatic labeling machines, it is more cost-effective and suitable for smaller production runs.

3. Semi-automatic labeling machine: This type of machine combines the efficiency of automatic labeling machines with the flexibility of manual label applicators. It requires minimal operator intervention, making it ideal for medium-scale production environments.

4. Top labeling machine: This type of machine is specifically designed to apply labels onto the top surface of products. It is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics.

5. Wrap around labeling machine: This type of machine is designed to apply labels around the circumference of cylindrical products, such as bottles and cans. It ensures that labels are applied smoothly and accurately, even on curved surfaces.

6. Front and back labeling machine: This type of machine is capable of applying labels onto both the front and back surfaces of products in a single pass. It is commonly used in industries where products require labeling on multiple sides.

7. High-speed labeling machine: This type of machine is designed to apply labels onto products at a fast pace, making it suitable for high-volume production lines. It is equipped with advanced technology to ensure precise and consistent label application.

Custom Manufacturing Options for label application machine

When looking into custom manufacturing options for a label application machine, there are several key factors to consider. Some of the options to explore include the type of labels being applied, the speed and accuracy requirements of the machine, the size and shape of the products being labeled, and the available space for the machine.

One custom manufacturing option to consider is the type of labeling method used. For example, a machine can be designed for either pressure-sensitive labels, hot stamping labels, or sleeve labels. The machine can also be customized to apply multiple labels on a single product if needed.

Another option to explore is the speed and accuracy of the label application machine. Depending on the production volume and the desired efficiency, the machine can be designed to apply labels at different speeds and with varying degrees of precision. This can involve customization of the labeling mechanism, the conveyor system, and the control system of the machine.

The size and shape of the products being labeled will also impact the design of the label application machine. Customized fixtures and accessories may be required to ensure that the labels are applied correctly and securely on products of different shapes and sizes.

Finally, the available space for the machine should be considered when exploring custom manufacturing options. The machine can be designed to fit into existing production lines or workspaces, or it can be customized to be more compact or to have a smaller footprint if space is limited.

Overall, when exploring custom manufacturing options for a label application machine, it is important to consider all of these factors to ensure that the machine is tailored to meet the specific needs and requirements of the production process. By working closely with a manufacturer that specializes in custom machinery, businesses can create a label application machine that is efficient, reliable, and well-suited to their unique production needs.

List Quality Control and The Manufacturing Process of "label application machine"

Quality control for a label application machine involves several steps to ensure the finished product meets the necessary standards. First, the machine must be assembled correctly according to the manufacturer’s specifications. Each component must be inspected for defects or damage before installation.

During the manufacturing process, regular testing is conducted to check the machine’s performance and accuracy. This includes ensuring that labels are applied consistently and accurately onto the product. Any deviations from the desired outcome are immediately addressed and corrected.

Furthermore, the quality of the labels themselves is also important. The labels must adhere properly to the product and be free from any defects such as tears or misprints. Regular maintenance of the machine is essential to prevent malfunctions and ensure optimal performance.

The manufacturing process of a label application machine involves precision engineering and attention to detail. Each component is meticulously designed and fabricated using high-quality materials. Assembly is done with care to ensure that all parts fit together seamlessly.

Testing and calibration are key steps in the manufacturing process to ensure that the machine functions correctly. Any issues that arise during testing are addressed promptly to prevent defects in the final product.

Overall, quality control in the manufacturing process of a label application machine is essential to produce a reliable and accurate product that meets the needs of customers. By following strict quality control measures, manufacturers can ensure that their label application machines perform at their best and deliver consistent results.

How to use "label application machine"

A label application machine is a piece of equipment used to efficiently and accurately apply labels to products or packaging. To use a label application machine, start by loading the labels into the machine’s dispenser or feeder. Make sure the machine is set up correctly for the size and type of labels being used.

Next, adjust the settings on the machine to ensure that the labels are applied in the correct position on the products. This may involve adjusting the speed of the machine, the position of the label grip, or the pressure of the label applicator.

Once the machine is set up, place the products on the conveyor belt or platform of the machine. The machine will then automatically apply the labels to the products as they pass through the label applicator. It is important to regularly check the placement and quality of the labels to ensure that they are being applied correctly.

After labeling all the products, disconnect the power source and clean the machine according to the manufacturer’s instructions. This will help maintain the efficiency and longevity of the machine.

In conclusion, a label application machine is a useful tool for businesses looking to streamline their labeling process. By following these steps and maintaining the machine properly, you can effectively apply labels to your products with ease and accuracy.

List Properties and Terms of "label application machine"

A label application machine is a piece of equipment used in industries for applying labels to various products or packages. Some properties and terms associated with label application machines include:

1. Automatic operation: Label application machines are often automated, capable of applying labels quickly and accurately without the need for manual intervention.

2. High speed: These machines can operate at high speeds, allowing for efficient labeling of products in mass production environments.

3. Precision placement: Label application machines are designed to apply labels with precision and accuracy, ensuring that the labels are placed correctly on the products.

4. Adjustable settings: These machines typically have adjustable settings that allow for customization of label application, such as label size, placement, and application speed.

5. Versatility: Label application machines can be used to apply various types of labels, including pressure-sensitive labels, shrink sleeves, and wrap-around labels.

6. Integration capabilities: Some label application machines are equipped with integration capabilities, allowing them to be easily integrated into existing production lines.

7. User-friendly interface: Many label application machines feature a user-friendly interface that makes it easy for operators to set up and operate the machine.

8. Maintenance requirements: Regular maintenance is important to ensure optimal performance of label application machines and prevent breakdowns.

Overall, label application machines are essential tools for businesses looking to streamline their labeling processes and improve efficiency in product packaging.

List The Evolution history of "label application machine"

Label application machines have evolved significantly over the years with advancements in technology and automation.

1. Manual Labeling: In the early days, labeling was done manually with employees placing labels on products by hand. This method was slow and prone to errors.

2. Semi-Automatic Machines: As technology improved, semi-automatic label applicators were introduced. These machines could apply labels to products at a faster rate than manual labeling, but still required some level of human intervention.

3. Automatic Labeling Machines: With the rise of automation and robotics, automatic label application machines were developed. These machines are capable of applying labels to products at high speeds with minimal human involvement.

4. RFID Labeling: As technology continued to advance, RFID (radio-frequency identification) labeling machines were introduced. These machines not only apply labels but also encode them with information that can be read by RFID scanners.

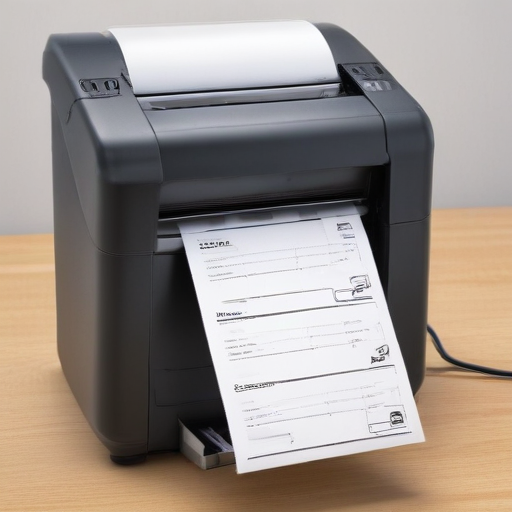

5. Print and Apply Systems: The latest evolution in label application machines is the print and apply system. These machines have the capability to print labels on demand and apply them to products in one seamless process.

Overall, label application machines have come a long way from manual labor-intensive processes to highly efficient and automated systems that save time, reduce errors, and increase productivity in various industries.

How to Select a Reliable label application machine

When selecting a label application machine for your business, there are a few factors to consider to ensure you are choosing a reliable and efficient machine.

First, consider the volume of labels you will be applying. If you have a high volume of labels to apply, you will want to choose a machine that is capable of handling that volume without sacrificing speed or quality. Look for machines that have high-speed capabilities and are designed for continuous use.

Next, consider the size and type of labels you will be applying. Make sure the machine you choose is compatible with the size and type of labels you will be using. Some machines are designed for specific types of labels, so be sure to choose one that meets your specific needs.

Also, consider the ease of use and maintenance of the machine. Look for machines that are user-friendly and easy to operate. Additionally, choose a machine that is easy to clean and maintain to ensure it continues to operate efficiently over time.

Finally, consider the reputation of the manufacturer. Choose a machine from a reputable manufacturer with a history of producing high-quality and reliable label application machines. Read reviews and ask for recommendations from other businesses to ensure you are choosing a machine that will meet your needs and stand the test of time.

By considering these factors, you can select a reliable label application machine that will help streamline your labeling process and improve overall efficiency in your business.

List "label application machine" FAQ

1. What is a label application machine?

A label application machine is a device used to apply labels onto products or packaging quickly and efficiently. This can include machines that apply labels to bottles, jars, boxes, or other types of containers.

-

How does a label application machine work?

Label application machines work by feeding labels through the machine, where they are then applied to products using various methods such as pressure-sensitive adhesive, hot melt glue, or shrink sleeve technology. -

What are the benefits of using a label application machine?

Using a label application machine can greatly increase productivity by applying labels quickly and accurately. It also reduces the risk of human error and ensures consistent labeling on all products. -

Are label application machines easy to operate?

Most label application machines are designed to be user-friendly and require minimal training to operate. Some machines are even equipped with touchscreen interfaces for easy programming and troubleshooting. -

What types of labels can be applied with a label application machine?

Label application machines can be used to apply a variety of labels including paper, plastic, vinyl, and holographic labels. They can also handle different label shapes and sizes. -

Are label application machines customizable?

Yes, many label application machines can be customized to meet specific requirements such as label placement, speed, and application method. This allows for flexibility in labeling different types of products.

Top 10 FAQ with answer about label application machine for Buyer Sourcing from China

1. What types of label application machines can I source from China?

There are various types of label application machines available from China, including semi-automatic, automatic, and fully automatic machines for applying labels on bottles, jars, boxes, and other packaging. -

What are the main features to look for in a label application machine?

Key features to consider include speed, accuracy, ease of use, flexibility in handling different label sizes and shapes, and compatibility with various types of packaging materials. -

How do I ensure the quality of label application machines sourced from China?

It is important to conduct thorough research on the manufacturer or supplier, request samples for testing, and inspect the machines before finalizing the purchase to ensure they meet your quality standards. -

Can I customize label application machines according to my specific requirements?

Yes, many manufacturers in China offer customization services to tailor the machines based on your specific needs, such as labeling speed, label placement accuracy, and compatibility with different label materials. -

What are the typical lead times for sourcing label application machines from China?

Lead times can vary depending on the complexity of the machine and customization requirements, but it is advisable to plan ahead and allow for at least 4-8 weeks for production and shipping. -

Are there any certifications or standards I should look for when sourcing label application machines from China?

It is recommended to ensure that the machines comply with international quality standards such as CE, ISO, and FDA certifications to guarantee safety and performance. -

What is the typical price range for label application machines from China?

Prices can vary based on the type, size, and features of the machine, but generally, you can expect to pay anywhere from $1,000 to $10,000 or more for a label application machine sourced from China. -

How do I handle shipping and logistics when sourcing label application machines from China?

It is advisable to work with a trusted freight forwarder or shipping agent who can assist with customs clearance, import duties, and arranging transportation for the machines to your location. -

What after-sales support and warranty options are available for label application machines sourced from China?

Many manufacturers offer warranty periods, technical support, and spare parts availability for their machines to ensure ongoing operational efficiency and maintenance. -

How can I ensure a smooth and successful sourcing experience for label application machines from China?

To ensure a positive sourcing experience, it is crucial to communicate clearly with the supplier, conduct thorough due diligence, inspect the machines before shipment, and establish a strong relationship based on trust and transparency.