List Technical Parameters of “manual packing machine”

A manual packing machine is a mechanical device used for packaging products. This machine is designed to help package various products in various sizes, using various materials. The machine can be used in various industries such as food and beverage, pharmaceutical, and other industries that require packaging. The following are the technical parameters of a manual packing machine:

1. Size and capacity: The size of the manual packing machine varies on the type of packaging it is meant for. The capacity also depends on the size and type of packaging.

2. Material used: The manual packing machine can package a wide range of materials such as plastics, paper, aluminum foil, and other suitable materials.

3. Power consumption: The manual packing machine consumes less power compared to other types of packing machines. It is designed to be energy-efficient to reduce power consumption.

4. Speed: The manual packing machine has a slower pace when it comes to packaging products due to manual operations. However, this does not affect its efficiency as it can still package products at a reasonable rate.

5. Automation: The manual packing machine is a non-automated packaging machine. It requires human input to package products.

6. Maintenance: The manual packing machine requires minimal maintenance due to its simple design. However, it should be regularly cleaned to ensure its efficiency.

7. Cost: The manual packing machine is an affordable packaging machine compared to other types of packing machines. The machine requires less investment initially and is a cost-effective packaging solution.

In conclusion, the manual packing machine is an excellent option for small and medium-sized businesses that require a simple and inexpensive packaging solution. The machine is easy to operate, maintain, and consumes less power making it suitable for businesses looking to reduce their operating costs.

List Product features of “manual packing machine”

Manual packing machines are designed to aid packaging processes for a wide range of industries that need to pack their products manually. These machines come with unique features that make them a reliable solution for packaging products manually. Here are some essential product features that make these machines ideal for many businesses:

1. Versatile: Manual packing machines come in different sizes and shapes to suit many business needs and product types. This versatility makes it possible to pack a wide array of products, including food, medicine, cosmetics, and other industries.

2. Easy to Operate: Manual packing machines are user-friendly and easy to operate and do not require any specialized skill to use. This feature makes it an ideal machine for small businesses or companies that have limited space and cannot afford to hire skilled labor to operate the equipment.

3. Durability: Manual packing machines are built to last and can withstand heavy usage. The machines are made of high-quality materials like stainless steel, aluminum, and other metals that are resistant to wear and tear.

4. Saves Time: Manual packing machines are designed to increase efficiency and productivity in the packaging process. They help to speed up the packaging process and reduce production time, making it possible to handle a higher volume of orders in a shorter time.

5. Cost-effective: Manual packing machines are relatively inexpensive compared to other packaging equipment. They offer a cost-effective solution for small businesses or those on a tight budget.

6. Customizable: Manual packing machines are customizable, allowing for modifications in their design to meet specific customer needs. Customers can request features like additional labeling systems, infeed/outfeed systems, safety guards, and more.

7. Low Maintenance: Manual packing machines require minimal maintenance, reducing the overall cost of running the machine. This feature makes it possible for businesses to allocate more funds towards other activities necessary for business growth.

In conclusion, manual packing machines are a reliable and cost-effective solution for businesses with small to medium production units. Their versatility, easy-to-use features, durability, and cost-effectiveness make them a preferred choice for many small and medium-sized businesses that need a packaging solution that is both manageable and efficient.

List Application of “manual packing machine”

A manual packing machine is a device used for packaging different products in small to medium quantities without using automated processes. This type of machine is highly versatile and can be used across different industries. Specifically, here are some of the applications where manual packing machines are most useful:

1. Food industry – Manual packing machines are highly suitable for the food industry, where packaging must follow strict safety and hygiene regulations. These machines can be used to pack different types of food such as candies, nuts, and dried fruits.

2. Cosmetic industry – In the cosmetic industry, manual packing machines are used to package small quantities of products such as lip balms, hand creams, and small cosmetic samples.

3. Pharmaceutical industry – Hand-held manual packing machines are used to package medicines in small quantities. This type of machine offers greater control over the packaging process and reduces the chances of contamination.

4. Hardware industry- In the hardware industry, manual packing machines are used to package small to medium quantities of nails, screws, and bolts.

5. E-commerce companies – With the rise of e-commerce companies packing machine companies are developing different types of manual packing machines for online sellers. These machines can be used to package small to medium sizes of items that are ordered online such as jewelry, clothes etc.

6. Veterinary industry – Manual packing machines are even used by veterinaries for packaging animal drugs in appropriate sizes and quantities.

In conclusion, a manual packing machine is used in a wide range of industries. The machine’s versatility and ease of use have made it a popular choice for small to medium-sized businesses who require a machine that can package products quickly, efficiently, and hygienically. It is an ideal solution for companies who require packaging schemes and customizations that are not achievable by automated machines.

List Various Types of “manual packing machine”

There are several types of manual packing machines on the market today. These machines are designed to automate various manual packing tasks, making them faster, more efficient, and more consistent. Some of the most common types of manual packing machines include:

1. Hand-held tape dispensers – These machines are used to apply tape to cardboard boxes manually. They feature a built-in tape cutter and a brake mechanism that allows the user to apply an even amount of tape to the box.

2. Heat sealers – Heat sealers are a popular type of machine used for sealing poly bags, Mylar bags, and other types of packaging materials. These machines use heat to melt the plastic and create a seal that is both airtight and watertight.

3. Manual strapping machines – These machines are used to secure goods and packages together using straps. They are ideal for securing heavy or bulky items that require strong support during transportation.

4. Hand-operated carton sealing machines – These machines are designed to apply tape to cardboard boxes. They come in various sizes and styles, and many feature an adjustable height to accommodate boxes of different sizes.

5. Label applicators – These machines are used to apply labels to packaging materials, such as boxes, bags, and containers. They come in various sizes and styles and can be either manual or semi-automatic.

Overall, manual packing machines can help streamline the packing process, increase productivity, and reduce errors and inefficiencies. They are an essential tool for any business that needs to package products quickly and efficiently.

List The Process of “manual packing machine”

Manual packing machines are used to package various types of products or materials manually. The packing process involves weighing, wrapping, sealing, labeling and sometimes boxing the final product. Listed below are the steps involved in the process of manual packing machine:

1. Material Preparation: Before the packing process, the materials for packing must be prepared by sorting, weighing and arranging them into various sizes and shapes.

2. Filling and Weighing: Once the materials are sorted, they are placed into the filling unit of the manual packing machine. The machine weighs the materials to a predetermined weight.

3. Wrapping: After the weighing is done, the machine wraps the materials with the appropriate film or paper, provided as per the material being packed. The wrapping material covers and seals the product.

4. Sealing: After wrapping the paper/film is sealed with the help of heat or adhesives to ensure the product inside the wrapper remains fresh and tamper-proof.

5. Labeling: The next step is labelling the product with the necessary information like expiry date, batch number, manufacturer details, etc. Labels can be added either manually or by using a separate labeling machine.

6. Boxing: In some cases, after the above steps are completed, the product is placed inside a box to provide additional protection.

7. Final Inspection: The packaging process is completed after a final inspection is completed to ensure that the product has been packed correctly. Once the inspection is completed, the box is closed, and it is packaged for dispatch or storage.

Manual packing machines are cost-effective and ideal for small scale operations, as they are simple to operate, have a lower initial cost, and require minimum maintenance. However, they are not suitable for large scale operations due to slower production rates and increased labor costs.

How to use “manual packing machine”

A manual packing machine is an easy-to-use device designed for small-scale businesses that require precise packaging of products. With this machine, the user can efficiently pack a wide range of products such as food, pharmaceuticals, cosmetics, and more. The manual packing machine is made up of different parts, including a container, filling unit, sealing unit, and frame.

To use the manual packing machine, first, sanitize the machine and its parts. Next, set up the machine by attaching the filling unit to the container and sealing unit. Adjust the settings of the machine to match the packaging requirements, such as the desired amount of product and the sealing time. Next, fill the product into the container using a spoon or funnel and close the lid.

After filling, place the container into the sealing unit and press the sealing arm for a few seconds. The heat generated by the sealing unit will melt the sealant on the lid to create an airtight seal. Once the sealing is complete, remove the container from the machine and repeat the process for the next product.

It is essential to ensure that the container is correctly positioned and that the amount of product filled is accurate. Also, carefully adjust the sealing time and temperature to avoid overheating, which can cause damage to the product and the container.

In conclusion, the manual packing machine is an easy-to-use device that requires a bit of practice for efficient use. The machine ensures accurate packaging of a wide range of products, making it an essential tool for many small-scale businesses.

List Properties of “manual packing machine”

A manual packing machine is a type of equipment used for packaging goods and products in the industrial, retail, and food sectors. It is designed to meet the demand for cost-effective and efficient packing solutions in small and medium-sized businesses. Below are some of the properties of a manual packing machine:

1. Simple Design: A manual packing machine is usually designed with a simple structure, which makes it easy to operate and maintain.

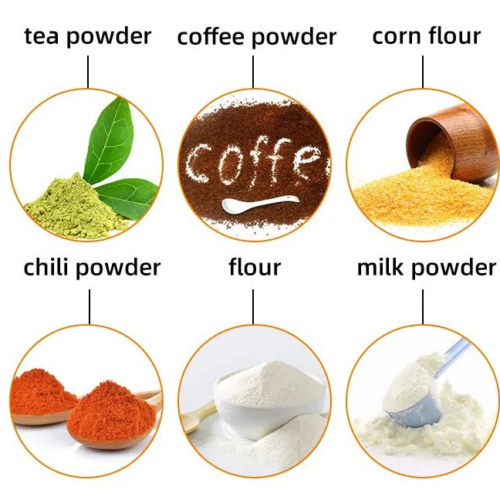

2. Versatility: This packing machine is highly versatile, as it can package a wide range of products, including powders, granules, liquids, and semi-solid materials.

3. Low Cost: Manual packing machines are relatively cheaper than fully-automatic packing machines, making them an affordable option for small businesses or start-ups.

4. Portability: Many manual packing machines have a compact design that makes them portable and easy to move from one location to another.

5. Labor-Saving: Manual packing machines can help to save labor costs as they require only one or two people to operate.

6. Energy Efficiency: Most manual packing machines are energy-efficient and consume fewer resources than fully-automatic machines.

7. Safe: Manual packing machines are generally safe to operate, as they have numerous safety features that protect operators from accidents and injuries.

8. Durability: Manual packing machines are made of sturdy materials that can withstand the rigors of daily use, making them highly durable.

9. Easy to Clean: Due to the simple design, manual packing machines are easy to clean and maintain.

Overall, a manual packing machine is an essential tool for businesses that require a cost-effective and efficient packaging solution. It offers numerous benefits, including versatility, portability, energy efficiency, and durability.

List “manual packing machine” FAQ

1. What is a manual packing machine?

A manual packing machine is a device that is used to pack products into a container by manually operating it.

2. How does a manual packing machine work?

A manual packing machine works by placing a bag or container under the machine’s spout, and then filling it with the desired product by manually turning a crank or lever until the desired amount is reached.

3. What types of products can be packed using a manual packing machine?

A manual packing machine can pack almost any type of product, including powders, granules, liquids, and solids.

4. What are the benefits of using a manual packing machine?

The benefits of using a manual packing machine include reduced labor costs, increased efficiency, accuracy, and versatility.

5. How much does a manual packing machine cost?

The cost of a manual packing machine varies depending on its size, capacity, and features. Entry-level models can cost as little as a few hundred dollars, while high-end models can cost thousands.

6. Can a manual packing machine be customized to meet specific needs?

Yes, many manufacturers offer customization options to suit various production requirements, such as different bag sizes and materials.

7. How easy is it to maintain a manual packing machine?

A manual packing machine is relatively easy to maintain and generally requires regular cleaning and lubrication.

8. Is it safe to operate a manual packing machine?

Yes, manual packing machines are generally safe to operate, provided that operators follow proper safety precautions and operating procedures.

9. Can a manual packing machine be used in a sterile environment?

Yes, manual packing machines can be used in sterile environments, provided they are designed and constructed to meet strict sanitation and hygiene standards.

10. How long does a manual packing machine last?

The lifespan of a manual packing machine depends on various factors, including frequency of use, maintenance, and environmental conditions. With proper care, a manual packing machine can last for several years.