Understanding the Napkin Paper Machine

Definition and Primary Function

Napkin paper machines are specialized machines utilized in the production of paper napkins, a staple in dining establishments, households, and various other settings. These machines are engineered to manufacture napkins efficiently, ensuring they are of high quality, consistent in size, and aesthetically pleasing. The primary function revolves around processing large rolls of paper, embossing them, automatically folding, and then cutting them into ready-to-use napkins. The machines can be configured to produce napkins of different sizes and shapes, catering to diverse market demands.

Key Components and Their Roles

- Transmission Belt Drive System: This component ensures the smooth operation of the machine, driving the production process by ensuring all parts move in a synchronized manner.

- Embossing Rollers: These are crucial for providing the napkins with textures and patterns, which are not just aesthetically pleasing but also enhance the functional properties of the napkins, such as absorbency.

- Cutting Modules: Equipped with sharp, durable blades, the cutting modules are responsible for ensuring that the napkins are cut precisely and uniformly.

- Folding Mechanisms: These mechanisms are responsible for folding the napkins into the desired shapes and sizes, which can be adjusted according to specific requirements.

- Printing Units: Some napkin paper machines come with printing units that allow for the printing of designs, logos, or text onto the napkins, providing an additional layer of customization.

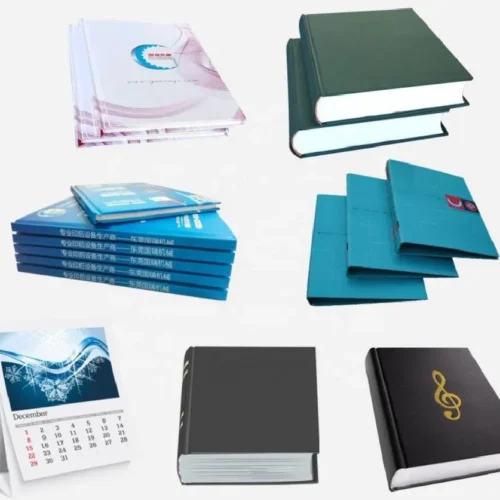

Types and Applications of Napkin Paper Machines

Different Models and Their Specific Uses

Napkin paper machines come in various models, each designed to meet specific production needs. For instance, the Fully Automatic Napkin Paper Making Machine from XiMeng is known for its high production speed, low noise, and suitability for family-type production. It can also print up to two colors and emboss various types of napkin paper, providing versatility in production.

Industries that Benefit from These Machines

- Hospitality Industry: Restaurants, hotels, and cafes utilize napkins as a fundamental part of their service.

- Airlines and Railways: In-flight and on-train meals require the use of napkins, often customized with the company’s logo.

- Healthcare Industry: Napkins are used in healthcare settings for hygiene purposes and are often disposed of after a single use to maintain cleanliness and prevent cross-contamination.

- Personal Use: Households use napkins daily, making them a staple in domestic settings.

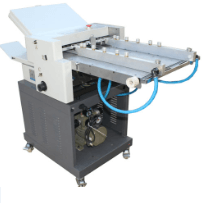

Features of the Fully Automatic Napkin Paper Making Machine

Transmission Belt Drive System

The transmission belt drive system is pivotal in ensuring the seamless operation of the machine. It facilitates the smooth transition of the paper through various stages of production, from embossing to cutting, without causing tears or disruptions in the process.

Production Speed and Noise Considerations

With a production speed that can reach up to 800 sheets/minute, the Fully Automatic Napkin Paper Making Machine is designed to cater to high-demand production while maintaining a low-noise operation, making it suitable for various working environments.

Printing and Embossing Capabilities

The machine boasts the ability to print up to two colors and can emboss various types of napkin paper, providing options for customization and enhancing the aesthetic and tactile appeal of the final product.

Safety Features and Automatic Functions

Safety and efficiency are paramount in the design of the machine. It features an automatic stop function during paper cutting and a synchronous transmission function, ensuring safety and enhancing production speed.

The Manufacturing Process

The manufacturing process of napkin papers involves several stages:

- Raw Material Preparation: Large rolls of paper are prepared, ensuring they are of the right quality and thickness.

- Embossing: The paper is passed through embossing rollers that imprint desired textures and patterns onto the napkins.

- Printing: If the machine has printing capabilities, designs, logos, or text are printed onto the napkins at this stage.

- Folding: The paper is then folded into the desired shape and size using the machine's folding mechanisms.

- Cutting: The folded paper is cut into individual napkins using the cutting modules.

- Quality Control: Each batch of napkins is checked for quality, ensuring consistency in size, texture, and print.

How to Choose the Right Napkin Paper Machine Supplier in China

China is a hub for manufacturing, and when it comes to napkin paper machines, the country boasts several reputable suppliers. Here's how to choose the right one:

- Reputation: Research the supplier's reputation in the market. Look for reviews, testimonials, and any industry awards or recognitions.

- Customization Options: Ensure the supplier offers customization options to cater to specific production needs.

- After-sales Service: A good supplier will provide robust after-sales service, including machine installation, maintenance, and troubleshooting.

- Price and Quality: While cost is a factor, it shouldn't compromise the quality. Ensure the machine is made of durable materials and boasts advanced features.

Using the Machine: A Step-by-Step Guide

- Installation: Begin by setting up the machine in a suitable location, ensuring there's enough space for operation and maintenance.

- Configuration: Configure the machine settings, including paper size, embossing patterns, and printing designs if applicable.

- Operation: Start the machine, feed the raw paper, and monitor the production process, ensuring it runs smoothly.

- Maintenance: Regularly clean the machine, lubricate moving parts, and check for any wear and tear. Schedule periodic maintenance checks with the supplier.

Questions International Buyers Should Ask Chinese Suppliers

- What is the warranty period for the machine?

- Do you provide installation and training services?

- What are the customization options available?

- How do you handle machine repairs and parts replacement?

- What are the shipping and delivery timelines?

FAQ Tips about Napkin Paper Machine

1. What materials are used in the construction of the napkin paper machine?

- Most napkin paper machines are constructed using high-grade stainless steel and other durable materials to ensure longevity and compliance with hygiene standards.

2. Can the machine handle different types of paper materials?

- Yes, most machines are versatile and can handle various paper grades. However, it's essential to consult with the manufacturer about specific paper types.

3. How energy-efficient are these machines?

- Modern napkin paper machines are designed with energy efficiency in mind, ensuring minimal power consumption without compromising performance.

4. Are there any safety features incorporated into the machine?

- Absolutely. Safety features like emergency stop buttons, overload protection, and automatic shutdown in case of malfunctions are standard in most models.

5. How does the electronic counting system work?

- The electronic counting system accurately counts the number of napkins produced, ensuring consistent batch sizes and aiding in inventory management.

6. What are the environmental considerations of using a napkin paper machine?

- Many manufacturers focus on sustainability, designing machines that produce minimal waste and are compatible with recycled paper.

7. How often should the embossing rollers be replaced or maintained?

- The longevity of embossing rollers varies based on usage. Regular inspection for wear and tear is recommended, with replacements typically needed every few years, depending on usage frequency.

8. Can the machine be integrated into an existing production line?

- Most napkin paper machines are designed to be modular and can be integrated into existing production lines with minimal adjustments.

9. What kind of training is required to operate the machine?

- While the machines are designed to be user-friendly, suppliers often provide comprehensive training on operation, troubleshooting, and maintenance.

10. How does the machine ensure consistent napkin quality?

- Through precise calibration, high-quality construction, and regular maintenance, the machine ensures that each napkin produced meets the set quality standards.

11. Are there any software updates or technological upgrades available periodically?

- Yes, as technology advances, manufacturers often release software updates or hardware upgrades to enhance machine performance and introduce new features.

12. What factors influence the price of a napkin paper machine?

- Factors include the machine's capacity, features, brand reputation, customization options, and after-sales services provided.

13. How do I troubleshoot common issues with the machine?

- The user manual typically provides a troubleshooting guide. However, for complex issues, it's recommended to consult the supplier or manufacturer directly.

14. Can the machine produce napkins with custom designs or branding?

- Yes, with the appropriate printing and embossing setups, the machine can produce napkins with custom designs, logos, and branding.

15. What are the shipping and installation considerations for international buyers?

- It's essential to discuss shipping logistics, installation services, and potential customs duties or import taxes with the supplier before finalizing the purchase.