List Technical Parameters of “orbital stretch wrap machine”

An orbital stretch wrap machine is a piece of equipment used to wrap items, usually pallets, in a protective film. This film is stretched tightly around the items, forming a secure and stable package that can withstand heavy handling, long-term storage, and transportation. The technical parameters that define the performance and capabilities of an orbital stretch wrap machine include:

1. Machine size: The overall dimensions of the machine will determine its footprint and the space required for installation.

2. Max wrapping height: This parameter determines the maximum height of the load that can be wrapped.

3. Max wrapping weight: This parameter determines the maximum weight of the load that can be wrapped.

4. Film thickness: This parameter refers to the thickness of the film used for wrapping. It affects the strength, durability, and puncture resistance of the wrap.

5. Film width: This parameter refers to the width of the film used for wrapping. It affects the coverage area and the efficiency of the wrapping process.

6. Conveyor speed: This parameter refers to the speed at which the items are moved through the wrapping process. It affects the throughput and the quality of the wrapping.

7. Turntable speed: This parameter refers to the speed at which the turntable rotates during the wrapping process. It affects the stability and wrapping quality of the load.

8. Film tension: This parameter refers to the amount of tension applied to the film during wrapping. It affects the tightness and security of the wrap.

9. Control system: This parameter refers to the software and hardware used to operate and monitor the machine. It affects the ease of use and the accuracy of the wrapping.

An orbital stretch wrap machine is a versatile and reliable solution for wrapping large items. By adjusting its technical parameters to suit different loads, it can produce consistent and high-quality wraps that protect items during storage and transportation.

List Product features of “orbital stretch wrap machine”

An orbital stretch wrap machine is a type of packaging equipment that is used to wrap goods securely. It is an automated machine that wraps a stretch film around a product, ensuring that the product is tightly packed. Some of the key features of an orbital stretch wrap machine include:

1. Flexibility: An orbital stretch wrap machine is designed to wrap both uniform and irregular-shaped products in a fast and efficient manner. This machine is suitable for wrapping products of varying sizes and shapes.

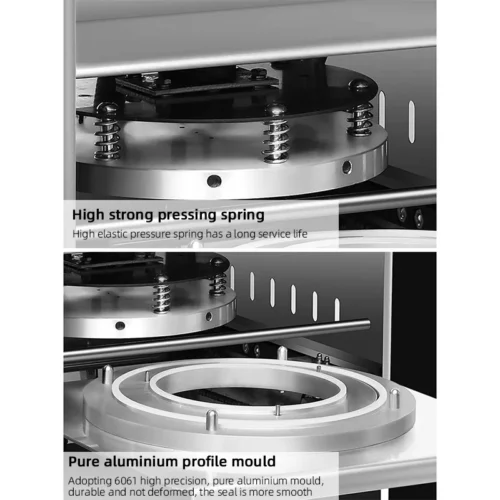

2. Durability: These machines are made from durable materials that can withstand the rigours of heavy-duty use. They are engineered to deliver reliable service for many years.

3. Speed: An orbital stretch wrap machine is capable of wrapping products at high speeds. The machine can wrap dozens of products in a short amount of time, allowing for increased productivity.

4. Precision: These machines are designed to wrap products with precision. They use advanced technology to apply the stretch film evenly and tightly around the product, ensuring that it is fully protected.

5. Easy to Operate: An orbital stretch wrap machine is easy to operate, even for inexperienced users. It comes with a user-friendly interface that makes it easy to adjust the settings and wrap products.

6. Minimal Maintenance: These machines require minimal maintenance, which helps to reduce downtime and increase productivity. They are designed to be easy to clean and maintain, making them perfect for busy production environments.

7. Enhanced Safety: An orbital stretch wrap machine is designed with safety features that help to prevent accidents and injuries. These features include safety guards, emergency stop buttons, and other safety mechanisms that ensure that the operator and other personnel are safe while the machine is in operation.

8. Eco-Friendly: Some of these machines are designed to use eco-friendly stretch film that is recyclable and reduces the carbon footprint of the packaging process. This makes them sustainable and environmentally-friendly.

In summary, an orbital stretch wrap machine is a highly efficient and versatile packaging equipment that offers numerous benefits. With its flexibility, durability, precision, speed, ease of use, minimal maintenance, enhanced safety, and eco-friendliness, it is an ideal choice for businesses of all sizes and industries.

List Application of “orbital stretch wrap machine”

Orbital stretch wrap machines refer to an innovative device designed to wrap large items quickly, efficiently, and cost-effectively. The machines are revered for their versatility, and they can be utilized in a broad range of industries and applications across the globe. Some of the most common applications of the orbital stretch wrap machine include:

1. Packaging of construction materials – The machine can be used to wrap materials like lumber, masonry, insulation materials, and roofing materials.

2. Wrapping of automotive parts – Many automotive parts, including engines, transmissions, and tires, require careful wrapping and protection during transportation. Orbital stretch wrap machines can be used in this case.

3. Pallet wrapping – The machine may be used to wrap large pallets, ensuring that the contents of the pallet remain secure during shipping and distribution.

4. Furniture wrapping – Orbital stretch wrap machines may be used to wrap furniture, protecting the pieces from dust and other contaminants.

5. Pharmaceutical packaging – In the pharmaceutical industry, orbital stretch wrap machines may be used to wrap medical equipment and supplies.

6. Electronics packaging – In the electronics industry, the machine may be used to wrap delicate electronic components, preventing damage during transportation.

7. Food and beverage packaging – In the food and beverage industry, orbital stretch wrap machines may be used to wrap items like bottled drinks and food containers to retain freshness.

8. Wrapping of textiles – Textile manufacturers can use the machine to wrap bolts of fabric and other textile products, ensuring they remain clean and dust-free.

In conclusion, the orbital stretch wrap machine is a versatile and flexible tool that can be used in various industries. The ability to wrap large items quickly, efficiently, and cost-effectively has made this machine popular, and it has become a critical component of many manufacturing and shipping operations worldwide.

List Various Types of “orbital stretch wrap machine”

There are different types of orbital stretch wrap machines designed for different applications, depending on the load being wrapped, the material being used, and the production process. These machines are used for automatic wrapping of products with stretch film to protect them during transit, storage, or shipment.

1. Rotary arm stretch wrap machine: This type of machine uses a rotating arm to wrap the load while it stays stationary on a turntable. This method is ideal for wrapping unstable or lightweight loads as it prevents any shifting during wrapping.

2. Turntable stretch wrap machine: Turntable stretch wrap machines have a rotating turntable on which the load is placed. The film is wrapped around the load as the table rotates. This type of machine is best suited for wrapping palletized loads.

3. Ring stretch wrap machine: Ring stretch wrap machines are designed for high speed wrapping of cylindrical items, bottles, cans, and other products. The item passes through the ring and the film is wrapped around it.

4. Horizontal stretch wrap machine: This type of stretch wrapping machine is primarily used for long items like pipes or tubes. The item is placed horizontally on the machine and the film is wrapped around it as the machine rotates the load.

5. Vertical stretch wrap machine: Vertical stretch wrap machines are ideal for wrapping unstable or delicate products that cannot be wrapped horizontally. The product is placed on a turntable and the machine wraps the product from the top down.

6. Mobile stretch wrap machine: Mobile stretch wrap machines are designed for wrapping products that are too large or heavy to move. These machines are mounted on a trailer or a movable platform, making it easier to wrap products on site.

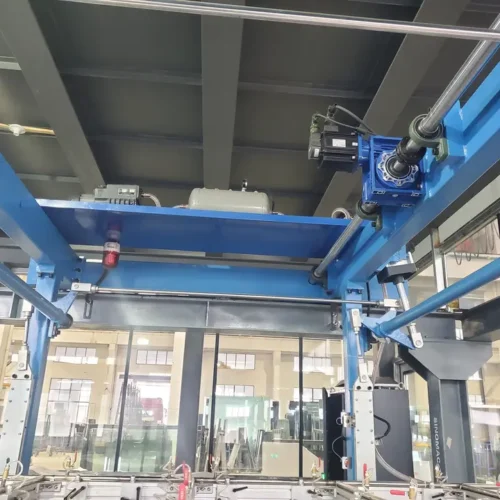

7. Automatic conveyorized stretch wrap machine: This type of machine is designed for high volume production lines and can handle a wide range of products. The machine automatically wraps and seals the film around the product, and the conveyor moves the wrapped product to the next station.

In conclusion, these are some of the main types of orbital stretch wrap machines you can find in the market. Choosing the right type of machine depends on the size and shape of the product being wrapped, the production speed, and the material being used.

List The Process of “orbital stretch wrap machine”

Orbital stretch wrap machine is a process that is used in the packaging industry to wrap products and protect them during transit. The process involves using a wrapping machine to apply stretch film around a product. Here are the steps involved in the process:

1. Product placement: The product is placed on the turntable or infeed conveyor of the orbital stretch wrap machine. The turntable revolves to place the product under the wrapping machine.

2. Stretch film placement: The stretch film is loaded onto the stretch film carriage of the machine.

3. Stretch film application: The stretch film is then applied to the product in a horizontal direction by the wrapping machine. The stretch film carriage moves down and around the product, applying a layer of film to hold the product in place.

4. Film tension: A tension control system will stretch the film to the desired level before it is applied to the product. This ensures that the stretch film is strong enough to keep the product secure during transit.

5. Cutting and sealing: Once the product has been wrapped, the stretch film is cut and sealed. This ensures that the film stays in place and does not unravel during transit.

6. Delivery: The wrapped product is then removed from the wrapping machine and is ready for delivery.

The orbital stretch wrap machine is an efficient way of protecting products during transit. It can be used to wrap products of various shapes and sizes, and the stretch film used can be customized to meet the specific needs of the product being wrapped.

How to use “orbital stretch wrap machine”

An orbital stretch wrap machine, also referred to as a stretch wrapping machine, is a piece of machinery that is used to wrap and secure products onto pallets using a plastic film wrap. It is quite common in warehouses, manufacturing, and distribution centers where large volume product handling is needed. The machine operates by rotating the product on a turntable, moving the film carriage along the vertical mast as the film spinning arm spirals it around the product.

Here’s how to use an orbital stretch wrap machine:

1. Prepare the pallet – Ensure that the pallet is set appropriately according to the machine’s specifications. It should be placed within the machine’s wrapping area similar to other packaging operations.

2. Load the film – Mount the stretch film roll, and thread the film through the carriage. Attach it to the turntable’s adjustable clamps.

3. Set up the machine – Adjust the wrapping tension, cycle settings, and film counter as per your requirements. Verify that the film carriage and tension rollers are in place and that the cut and seal operation is functioning well.

4. Place the product – Load the product onto the pallet and, if necessary, stabilizing it with bands or stretch wrap.

5. Start the machine – Initiate the machine via controls or push-button. The film carriage automatically wraps around the product while the turntable slowly spins.

6. Monitor the operation – Ensure that the wrap application is uniform and that your product’s load is secured. Observe the process from time-to-time, making adjustments if necessary.

7. Remove the finished product – Finally, remove the wrapped pallet from the machine and transport it to its expected placement.

In summary, an orbital stretch wrap machine simplifies and secures product wrapping operations. It offers benefits such as improved efficiency, consistency, and reduced product damage. With proper installation, operation, and maintenance, the machine can easily be integrated into various packaging applications.

List Properties of “orbital stretch wrap machine”

An orbital stretch wrap machine is a versatile piece of equipment used in various industries to wrap and secure pallets. Some of the properties of this machine are:

1. Stretch Wrap Capability: It is designed to wrap different types of products and cartons securely. Stretch films of various widths and thicknesses can be used.

2. High speed: The machine wraps products quickly and efficiently while preventing damage.

3. Automated Process: The machine enables automated wrapping of products, thereby eliminating the need for manual labor. It minimizes the risk of injury and requires fewer personnel.

4. Versatility: The machine can wrap a range of product shapes and sizes. It is ideal for wrapping odd-shaped items and can adapt to various industries.

5. Durability: The machine is built to last. It can withstand harsh industrial environments and intense usage without breaking down or malfunctioning.

6. Economic benefits: The machine uses less stretch film, saving costs on material. The automated process also helps in reducing labor costs.

7. Serves multiple purposes: The machine can be used to wrap multiple products, including irregularly shaped items and thin or bulky items, making it a useful tool in many settings.

8. User-friendly: The machine is simple to operate and requires minimal maintenance. An operator can easily adjust the machine’s settings and customize it to suit specific needs.

The above properties make the orbital stretch wrap machine an essential tool in the packaging and distribution industry. Its versatility, durability, automated process, and cost savings make it a practical choice for many businesses. It is an investment that can improve the efficiency and overall operations of any enterprise.

List “orbital stretch wrap machine” FAQ

Q: What is an orbital stretch wrap machine?

A: An orbital stretch wrap machine is an automated packaging machine that wraps products with stretch film to secure and protect them during storage and transportation.

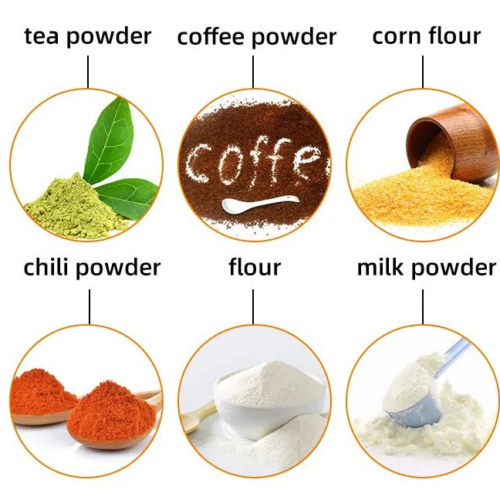

Q: What types of products can be wrapped with an orbital stretch wrap machine?

A: Orbital stretch wrap machines can wrap various types of products, including boxes, pallets, cylinders, pipes, and other irregularly shaped items.

Q: What are the benefits of using an orbital stretch wrap machine?

A: An orbital stretch wrap machine provides numerous benefits, including reduced labor costs, improved packaging efficiency, enhanced product protection, and increased production output.

Q: How does an orbital stretch wrap machine operate?

A: An orbital stretch wrap machine operates by placing the product on a turntable or platform, which spins the product while the stretch film is dispensed and wrapped around it. The machine can also cut and secure the film at the end of the process.

Q: What types of stretch film can be used with an orbital stretch wrap machine?

A: Orbital stretch wrap machines can use different types of stretch film, including blown, cast, or linear low-density polyethylene (LLDPE) films.

Q: What is the capacity of an orbital stretch wrap machine?

A: The capacity of an orbital stretch wrap machine depends on the size and model of the machine. Some machines can wrap products up to 100 inches tall and weigh up to 4,000 pounds.

Q: How long does it take to wrap a product using an orbital stretch wrap machine?

A: The duration of the wrapping process depends on the size and complexity of the product being wrapped and the speed of the machine. Typically, it takes between 20 seconds to two minutes to wrap a product.

Q: How does an orbital stretch wrap machine ensure product stability?

A: An orbital stretch wrap machine ensures product stability by applying consistent and tight wrapping around the product. The film stretches while being applied, creating a secure and stable load.

Q: What safety features should an orbital stretch wrap machine have?

A: An orbital stretch wrap machine should have safety features such as safety gates, emergency stop buttons, and safety sensors to prevent accidents and injuries.

Q: How can I maintain and care for my orbital stretch wrap machine?

A: You can maintain and care for your orbital stretch wrap machine by regularly cleaning and lubricating it, replacing worn parts as needed, and scheduling routine maintenance checks with a qualified technician.