List Technical Parameters of "packaging machine supplier"

Some technical parameters to consider when selecting a packaging machine supplier include:

1. Machine speed: The speed at which the packaging machine can operate is crucial in determining its efficiency and throughput. Consider the maximum output per minute that the machine can achieve.

2. Packaging material compatibility: Ensure that the machine supplier offers compatibility with the specific packaging materials required for your products, such as plastic film, cardboard, or metal.

3. Machine size and footprint: Consider the dimensions of the packaging machine to ensure it fits within your production facility and can be easily integrated into existing production lines.

4. Automation level: Determine the level of automation offered by the packaging machine supplier, such as manual, semi-automatic, or fully automatic operation, to meet your production needs.

5. Maintenance and support: Evaluate the availability of technical support, spare parts, and maintenance services provided by the supplier to ensure the continued operation and longevity of the packaging machine.

6. Customization options: Look for a supplier that offers customization options to tailor the packaging machine to your specific requirements, such as different packaging formats or branding features.

7. Energy efficiency: Consider the energy consumption and efficiency of the packaging machine to minimize operational costs and environmental impact.

8. Compliance and certifications: Ensure that the packaging machine supplier meets industry standards and certifications, such as CE, UL, or ISO, to guarantee the quality and safety of their products.

By evaluating these technical parameters, you can select a packaging machine supplier that meets your production needs and provides reliable and efficient packaging solutions.

List Product features of "packaging machine supplier"

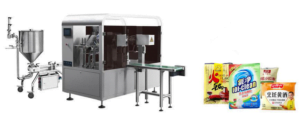

1. Wide Range of Packaging Machines: Our supplier offers a wide variety of packaging machines to suit the unique needs of each customer. Whether you need a filling machine, sealing machine, labeling machine, or all of the above, we have you covered.

2. Customizable Solutions: Our supplier understands that every customer has specific requirements when it comes to packaging. That's why we offer customizable solutions that can be tailored to meet your exact specifications, ensuring that you get the best possible packaging machine for your needs.

3. High-Quality Equipment: We only work with reputable manufacturers who produce high-quality packaging machines built to last. This means you can trust that the equipment you receive will be durable, reliable, and able to withstand the demands of your production line.

4. Expert Advice and Support: Our supplier has a team of experienced professionals who are ready to provide expert advice and support throughout the purchasing process. From helping you choose the right machine for your needs to providing installation and training, we are here to help every step of the way.

5. Competitive Pricing: We understand that cost is an important factor when choosing a packaging machine supplier. That's why we offer competitive pricing on all of our equipment, ensuring that you get the best value for your money without compromising on quality.

6. Excellent Customer Service: Our supplier prides itself on providing excellent customer service before, during, and after the sale. You can trust that we will be there to answer any questions or address any concerns you may have, ensuring a positive experience from start to finish.

List Application of "packaging machine supplier"

1. Food and beverage industry - Packaging machine suppliers provide equipment for industries producing food and beverages, such as canned goods, snacks, bottled drinks, and more. These machines help in the efficient and hygienic packaging of products to ensure their safety and freshness.

-

Pharmaceutical industry - Packaging machine suppliers cater to the pharmaceutical industry by providing machines for packaging medicines, capsules, tablets, and other medical products. These machines are designed to meet strict guidelines for cleanliness and accuracy in packaging.

-

Cosmetics industry - Packaging machine suppliers offer equipment for the cosmetics industry to pack products such as lotions, creams, perfumes, and makeup. These machines ensure that the packaging is appealing to consumers and maintains the quality of the product.

-

Electronic industry - Packaging machine suppliers provide machines for packaging electronic components, devices, and gadgets. These machines help in protecting delicate electronics from damage during shipping and handling.

-

E-commerce industry - With the rise of online shopping, packaging machine suppliers offer solutions for packaging products ordered through e-commerce platforms. These machines help in automating the packaging process, ensuring faster and more efficient delivery to customers.

-

Agricultural industry - Packaging machine suppliers also cater to the agriculture industry by providing equipment for packaging bulk produce such as fruits, vegetables, grains, and seeds. These machines help in extending the shelf life of agricultural products and maintaining their quality during transportation.

Overall, packaging machine suppliers play a crucial role in various industries by providing equipment that ensures products are packaged safely, efficiently, and attractively for consumers. Their solutions help in streamlining production processes, reducing labor costs, and maintaining the quality of products throughout the supply chain.

List Various Types of "packaging machine supplier"

1. Automatic packaging machine supplier: These suppliers specialize in providing automated packaging solutions that can efficiently package products in a variety of industries such as food, pharmaceuticals, and cosmetics.

2. Filling machine supplier: Filling machines are used to accurately fill containers with a specific quantity of liquid, granules, or powder. Suppliers of these machines offer a range of models suitable for different types of products.

3. Sealing machine supplier: Sealing machines are essential for ensuring that packaged products are properly sealed to maintain product freshness and prevent contamination. Suppliers of sealing machines offer a variety of options, including heat sealers, induction sealers, and vacuum sealers.

4. Labeling machine supplier: Labeling machines are used to apply labels to packaged products, providing essential information such as ingredients, expiry dates, and barcodes. Suppliers of labeling machines offer a range of solutions, including automatic and semi-automatic models.

5. Wrapping machine supplier: Wrapping machines are used to wrap products in protective packaging such as shrink film, stretch film, or bubble wrap. Suppliers of wrapping machines offer a variety of equipment designed to meet different packaging needs.

6. Coding and marking machine supplier: Coding and marking machines are used to print essential information on packaging, including batch numbers, expiry dates, and barcodes. Suppliers of these machines offer a range of solutions, including inkjet printers, thermal transfer printers, and laser marking systems.

7. Palletizing machine supplier: Palletizing machines are used to automatically stack products onto pallets for efficient transportation and storage. Suppliers of palletizing machines offer a range of solutions, including robotic palletizers and conventional palletizers.

8. Stretch wrapping machine supplier: Stretch wrapping machines are used to securely wrap products on pallets with stretch film for protection during shipping and storage. Suppliers of these machines offer a variety of models suitable for different industries and applications.

Custom Manufacturing Options for packaging machine supplier

As a packaging machine supplier, offering custom manufacturing options can be a valuable service to your clients. By providing custom solutions, you can better meet the specific needs and requirements of each customer, leading to higher customer satisfaction and loyalty.

One option for custom manufacturing is to offer personalized machine configurations. This could involve adjusting the size, shape, or features of the packaging machine to better suit a client’s production line or product packaging needs. By working closely with clients to understand their unique requirements, you can tailor the machine to their exact specifications.

Another custom manufacturing option is to offer design and engineering services to create completely bespoke packaging machines. This could involve developing new technologies, incorporating specific automation processes, or integrating specialized components to create a machine that is truly unique to the client’s needs. By leveraging your expertise and experience in packaging machine design, you can provide innovative solutions that set your clients apart from their competitors.

Additionally, offering customization options for packaging materials and components can further enhance your service offering. This could involve sourcing high-quality materials, such as eco-friendly or biodegradable options, or developing custom packaging designs that help clients differentiate their products on the market.

Overall, by offering custom manufacturing options as a packaging machine supplier, you can better serve your clients’ unique needs, foster strong relationships, and differentiate your business in a competitive market.

List Quality Control and The Manufacturing Process of "packaging machine supplier"

Quality control in the manufacturing process of a packaging machine supplier is crucial to ensure that the products meet the required standards and specifications. This process involves monitoring and inspecting every stage of manufacturing, from design and assembly to testing and packaging. Quality control measures include conducting regular checks on materials, components, and finished products to identify any defects or irregularities.

The manufacturing process of a packaging machine supplier typically begins with the design phase, where engineers develop concept drawings and specifications based on customer requirements. Once the design is approved, the manufacturing process moves to the assembly stage, where skilled technicians assemble the components and integrate the various parts of the machine.

During the assembly process, quality control checks are performed to ensure that the components fit properly, and all connections are secure. If any issues are identified, they are addressed immediately to prevent any defects in the finished product. Once the machine is fully assembled, rigorous testing is conducted to verify that it functions correctly and meets performance standards.

After passing all quality control tests, the packaging machine is prepared for packaging and shipping to customers. The packaging process ensures that the machine is protected during transportation and delivery to its final destination. Throughout the entire manufacturing process, the packaging machine supplier follows strict quality control protocols to maintain high standards and deliver reliable products to their customers.

How to use "packaging machine supplier"

A packaging machine supplier is a crucial partner for businesses in various industries that require efficient and reliable packaging solutions. When looking for a packaging machine supplier, it is important to consider several factors to ensure that you are getting the best equipment for your specific needs.

Firstly, it is essential to research and compare different packaging machine suppliers to determine who offers the most suitable equipment for your production requirements. Consider factors such as the type of packaging machines they offer, their technology and capabilities, as well as their reputation in the industry.

Once you have selected a packaging machine supplier, it is important to communicate your specific requirements and expectations clearly. Provide details about the type of products you need to package, the volume of production, and any special requirements or customization needed for the machines.

A reliable packaging machine supplier will work closely with you to understand your needs and provide recommendations on the best equipment for your business. They should also offer ongoing support, maintenance, and training to ensure that your packaging machines are operating efficiently and effectively.

In conclusion, choosing the right packaging machine supplier is essential for ensuring smooth and efficient packaging operations. By selecting a reputable supplier and clearly communicating your needs, you can invest in high-quality equipment that will streamline your production process and help you meet your business goals.

List Properties and Terms of "packaging machine supplier"

Packaging machine supplier refers to a company or entity that specializes in providing machinery and equipment used for packaging products in various industries. Some key properties and terms associated with packaging machine suppliers include:

1. Product range: Suppliers offer a variety of packaging machines, such as filling machines, sealing machines, labeling machines, and wrapping machines, to cater to different packaging needs.

2. Customization: Suppliers may offer customization services to tailor packaging machines to the specific requirements of their clients, such as modifying machine size, speed, or packaging materials.

3. Quality assurance: Suppliers ensure that their machines are made from high-quality materials and meet industry standards to guarantee optimal performance and durability.

4. Technical support: Suppliers provide technical support and maintenance services to help clients with troubleshooting, repairs, and machine modifications.

5. Training: Some suppliers offer training programs to educate clients on how to operate and maintain the packaging machines effectively and safely.

6. Supply chain management: Suppliers manage the supply chain of packaging materials, spare parts, and components required for the operation and maintenance of the machines.

7. Industry expertise: Suppliers often have extensive experience and knowledge of different industries, enabling them to recommend the most suitable packaging solutions for specific applications.

Overall, packaging machine suppliers play a crucial role in the packaging industry by providing clients with reliable, efficient, and cost-effective solutions to optimize their packaging processes.

List The Evolution history of "packaging machine supplier"

Packaging machines have a rich history that has evolved over the years. The concept of using machines to automate the packaging process dates back to the late 19th century when the first packaging machines were invented. These early machines were simple devices that helped speed up the process of packaging goods for transport and sale.

As technology advanced, so did the capabilities of packaging machines. In the mid-20th century, the development of more sophisticated machines allowed for greater efficiency and precision in the packaging process. These machines were able to handle a wider range of products and packaging materials, making them indispensable in the manufacturing industry.

In recent years, packaging machines have continued to evolve with the introduction of new technologies such as robotics and artificial intelligence. These advancements have further improved the efficiency and accuracy of packaging processes, while also reducing waste and increasing overall productivity.

Today, there are numerous packaging machine suppliers that offer a wide variety of machines to meet the diverse needs of different industries. These suppliers work closely with manufacturers to provide customized solutions that help optimize their packaging processes and improve overall efficiency.

Overall, the evolution of packaging machines has been a story of innovation and technological advancement, with suppliers playing a crucial role in driving progress and meeting the changing needs of the industry.

How to Select a Reliable packaging machine supplier

When selecting a reliable packaging machine supplier, there are several factors to consider to ensure you are getting the best quality equipment and services.

Firstly, it is essential to do thorough research on different packaging machine suppliers to understand their reputation in the industry. Look for reviews and testimonials from previous customers to gauge their reliability and customer satisfaction levels.

Secondly, consider the supplier's experience and expertise in the packaging industry. A supplier with years of experience is more likely to provide high-quality equipment and comprehensive support services.

Thirdly, evaluate the range of packaging machines offered by the supplier and ensure they meet your specific requirements. The supplier should have a variety of machines to choose from, including options for different types of packaging materials and production volumes.

Additionally, consider the supplier's technical support and after-sales services. A reliable supplier should offer prompt and efficient customer support to address any issues that may arise with the equipment.

Lastly, compare pricing and payment terms from different suppliers to ensure you are getting a competitive deal without compromising on quality. It is also important to establish a clear communication channel with the supplier to address any concerns or queries throughout the procurement process.

By considering these factors, you can select a reliable packaging machine supplier that meets your needs and provides quality equipment and services.

List "packaging machine supplier" FAQ

1. What types of packaging machines do you supply?

We supply a wide range of packaging machines including filling machines, sealing machines, labeling machines, and wrapping machines.

-

Can you customize packaging machines to meet specific requirements?

Yes, we can customize packaging machines to meet the specific needs of our customers, including speed, size, and packaging materials. -

What industries do you serve?

We serve a variety of industries including food and beverage, pharmaceuticals, cosmetics, and chemical industries. -

Do you provide installation and training for your packaging machines?

Yes, we provide installation and training services for all of our packaging machines to ensure they are properly set up and operated by our customers. -

What is the warranty on your packaging machines?

We offer a standard warranty on all of our packaging machines, with options for extended warranties available for purchase. -

Do you offer maintenance and support services for your packaging machines?

Yes, we offer maintenance and support services for all of our packaging machines to ensure they are running efficiently and effectively for our customers. -

How do I place an order for a packaging machine?

You can place an order for a packaging machine by contacting our sales team either by phone or email. Our team will work with you to determine the best machine for your needs and provide you with a quote and delivery timeline.

Overall, we strive to provide high-quality packaging machines, extensive customization options, and excellent customer service to meet the diverse needs of our customers in various industries.

Top 10 FAQ with answer about packaging machine supplier for Buyer Sourcing from China

1. How can I find a reliable packaging machine supplier in China?

You can start by researching online, attending trade fairs, and getting recommendations from other businesses in your industry.

-

What types of packaging machines can I find from Chinese suppliers?

Chinese suppliers offer a wide range of packaging machines, including filling machines, sealing machines, labeling machines, and more. -

What is the average lead time for a packaging machine order from China?

Lead times can vary depending on the supplier and the specific machine ordered, but it is typically around 30-60 days. -

Can I request customizations or modifications to a packaging machine from a Chinese supplier?

Yes, many Chinese suppliers offer customization options for their packaging machines to meet your specific needs. -

How can I ensure the quality of the packaging machine from a Chinese supplier?

You can request samples, visit the supplier's factory, and ask for references from other customers to ensure the quality of the packaging machine. -

What is the payment terms typically required by Chinese packaging machine suppliers?

Payment terms vary, but it is common for suppliers to require a 30% deposit upfront and the remaining balance before shipment. -

Do Chinese packaging machine suppliers provide installation and training services?

Yes, many suppliers offer installation and training services for an additional fee to help you set up and operate the packaging machine. -

How can I handle shipping and import duties for a packaging machine from China?

You can work with a freight forwarder or shipping agent to handle the shipping logistics and customs clearance for your packaging machine order. -

Are there any certifications or quality standards I should look for in a packaging machine supplier from China?

Look for suppliers who have certifications such as CE, ISO, or FDA to ensure that their packaging machines meet international quality standards. -

How can I handle any issues or disputes with a packaging machine supplier from China?

It is important to have clear communication with the supplier and address any issues promptly to resolve any disputes amicably. Consider working with a third-party mediator if needed.