List Technical Parameters of "packaging machinery company"

When evaluating a packaging machinery company, several technical parameters are critical to ensure the machinery meets the operational and strategic needs of a business. Here are key parameters:

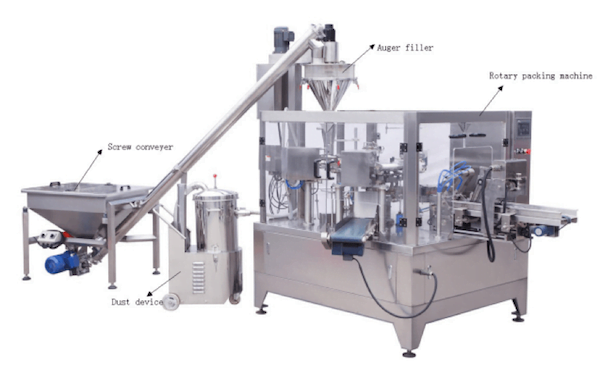

1. Machine Type and Capability: Identify whether the machinery includes form-fill-seal, labeling, carton forming, shrink wrapping, or other packaging types. Ensure it matches the product requirements (e.g., liquid, solid, granules).

2. Performance Specifications:

– Speed: Measured in units per minute (UPM). It’s crucial to know the maximum throughput.

– Accuracy: Precision in filling, labeling, or any other aspect can affect quality.

– Efficiency: The overall equipment effectiveness (OEE), considering availability, performance, and quality rates.

3. Material Compatibility: The ability to handle various packaging materials such as plastics, paper, aluminum, etc. Ensure machines can manage current and potential future materials.

4. Automation Level: Degree of automation from manual to fully automated systems. Consider integration capabilities with existing tech and scalability.

5. Flexibility and Adaptability: The ease of changing over for different products and packaging sizes. Modular designs enhance versatility.

6. Footprint: Space occupied by the machinery. Important for facility planning.

7. Compliance and Standards: Ensure machines meet industry standards and regulations (e.g., FDA for food and pharmaceuticals, CE marking for Europe).

8. Energy Consumption: Efficiency in power use, which impacts operating costs.

9. Maintenance and Support: Availability of service support, ease of maintenance, and availability of spare parts.

10. Technology Integration:

– IoT and Industry 4.0: For smart manufacturing capabilities.

– Software Compatibility: Integration with existing ERP, MES systems.

11. Safety Features: Compliance with safety standards (e.g., OSHA). Features like emergency stops, fail-safes, and guards.

Understanding these parameters helps in selecting the right machinery to enhance production efficiency, ensure quality, and meet regulatory requirements.

List Product features of "packaging machinery company"

Sure! Here are the product features of a packaging machinery company, kept concise within 300 words:

1. Versatile Application:

- Suitable for packaging various products, including food, beverages, pharmaceuticals, cosmetics, and industrial goods.

2. Automation Integration:

- Advanced automation capabilities to streamline packaging processes, reduce manual intervention, and increase efficiency.

3. Customizable Configurations:

- Machines can be tailored to meet specific customer needs and product specifications, offering adjustable settings and components.

4. High-Speed Performance:

- Equipped to handle high-speed operations ensuring rapid throughput and meeting high-demand production schedules.

5. Precision and Accuracy:

- High-precision technology for consistent, accurate filling, sealing, labeling, and other packaging tasks to maintain product quality.

6. Durability and Reliability:

- Built with robust materials and engineering excellence to ensure longevity and reliable performance over sustained periods.

7. User-Friendly Interface:

- Intuitive control panels with easy-to-use Software and touch screens for seamless operation and minimal training requirements.

8. Flexibility:

- Capable of handling different package sizes, shapes, and materials, including bags, bottles, cartons, and more.

9. Safety Features:

- Comprehensive safety mechanisms, including emergency stop functions, protective guards, and compliance with industry safety standards.

10. Energy Efficiency:

- Designed for minimal energy consumption to reduce operational costs and environmental impact.

11. Minimal Maintenance:

- Features requiring low maintenance, reducing downtime and ensuring continuous production cycles.

12. Integration with Existing Systems:

- Easy to integrate with existing production lines and ERP systems for enhanced workflow management and data tracking.

13. Quality Control Capabilities:

- Built-in quality control measures such as sensors, cameras, and software to detect defects and ensure product integrity.

14. After-Sales Support:

- Comprehensive customer support, including installation, training, troubleshooting, and spare parts services.

15. Compliance with Regulations:

- Machines designed to meet international industry standards and regulatory requirements for packaging.

By focusing on these features, a packaging machinery company can offer comprehensive, efficient, and innovative solutions to meet various industry needs.

List Application of "packaging machinery company"

Packaging machinery companies produce equipment designed for a variety of applications across different industries. Here are some common applications:

1. Food and Beverage Industry:

– Filling Machines: For liquids, solids, and powdered foods.

– Sealing and Capping: Ensuring freshness and preventing contamination.

– Labeling Machines: To provide nutritional information and branding.

2. Pharmaceutical Industry:

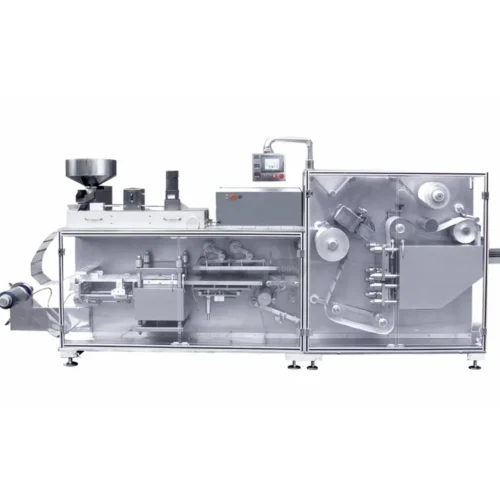

– Blister Packaging: For tablets and capsules.

– Vial Filling and Sealing: For vaccines and injectable drugs.

– Strip Packaging: For small doses and unit packaging.

3. Cosmetics and Personal Care:

– Tube Fillers: For creams, gels, and lotions.

– Bottle Fillers and Cappers: For shampoos, perfumes, and other liquids.

– Labelers and Shrink Wrappers: For appealing product presentation.

4. Chemical Industry:

– Drum Fillers: For bulk chemicals.

– Bagging Machines: For granular and powdered chemicals.

– Safety Sealers: To prevent leaks and contamination.

5. Automotive and Industrial:

– Component Packaging: For car parts and industrial components.

– Strapping and Bundling: For securing large or heavy items.

– Protective Packaging: To prevent damage during transit.

6. Consumer Goods:

– Shrink Wrapping: For electronics, toys, and appliances.

– Cartoning and Palletizing: For efficient storage and distribution.

– Scanning and Verification: To ensure packaging integrity and product traceability.

7. E-commerce and Logistics:

– Automated Packing Systems: For high-speed order fulfillment.

– Void Fillers and Cushioning: To protect products during shipping.

– Labeling and Barcoding: For inventory management and tracking.

8. Agricultural Products:

– Bagging and Pouching: For seeds, grains, and fertilizers.

– Tray Packers: For fresh produce.

– Vacuum Packaging: For extending the shelf life of perishable goods.

By utilizing advanced machinery and automation, these companies enable enhanced efficiency, consistency, and safety in packaging processes, reducing manual labor and mitigating risks associated with contamination or product damage.

List Various Types of "packaging machinery company"

Sure, the packaging machinery industry comprises various types of companies, each specializing in distinct areas of packaging technology. Here are some common types:

1. Form-Fill-Seal (FFS) Machinery Companies:

- Specialize in machinery that forms, fills, and seals packaging. Machines can be vertical (VFFS) or horizontal (HFFS).

2. Filling and Dosing Machinery Companies:

- Design machines to fill liquids, powders, and granules into containers. Common in the food, beverage, and pharmaceutical industries.

3. Labeling Machinery Companies:

- Focus on machines that apply labels to products. This includes pressure-sensitive labeling, shrink sleeve labeling, and glue-based labeling.

4. Wrapping and Bundling Machinery Companies:

- Provide machinery for wrapping products in film or paper, often used for bundling multiple items together.

5. Case Packing Machinery Companies:

- Specialize in machines that pack products into cases, crates, or boxes. This can include wrap-around case packers and drop packers.

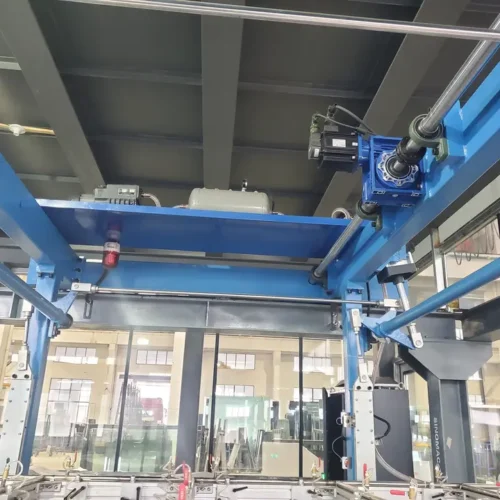

6. Palletizing Machinery Companies:

- Focus on machinery that arranges products on pallets for shipping and storage. Includes robotic and traditional palletizers.

7. Cartoning Machinery Companies:

- Manufacture machines for erecting, filling, and closing cartons. Used in the food, cosmetics, and pharmaceutical sectors.

8. Blister and Skin Packaging Machinery Companies:

- Specialize in thermoforming machines that create blister packs and skin packs, primarily for pharmaceuticals and consumer goods.

9. Vacuum and Modified Atmosphere Packaging (MAP) Machinery Companies:

- Provide machines that extend product shelf life by removing or replacing air inside the package.

10. Shrink and Stretch Sleeve Machinery Companies:

- Focus on machinery for applying shrink sleeves or stretch wraps, commonly used for bottles and jars.

11. Sealing Equipment Companies:

- Design machines for sealing packages using heat, adhesives, or other methods, ensuring the integrity and safety of the product inside.

12. Inspection and Quality Control Machinery Companies:

- Develop equipment to inspect and ensure the quality of the packaging and the product, often using X-rays, checkweighers, and vision systems.

These companies offer a range of machinery solutions catering to different needs across industries like food and beverage, pharmaceuticals, cosmetics, and consumer goods.

Custom Manufacturing Options for packaging machinery company

At PakTech Solutions, we understand that every business has unique packaging needs, and we offer a range of custom manufacturing options to meet those demands. Our state-of-the-art facility and experienced engineering team ensure that we can provide tailored solutions to enhance your packaging line’s efficiency, reliability, and cost-effectiveness.

1. Custom Design & Prototyping:

We collaborate closely with clients to design and prototype machinery that fits specific packaging requirements. Whether it’s specialized sealing mechanisms, custom-sized conveyors, or unique labeling systems, our design team uses advanced CAD software to create precise, functional prototypes.

2. Modular Systems:

Our modular packaging systems allow for easy integration of custom components. This flexibility means you can add or modify modules such as filling stations, cappers, or inspection systems as your packaging needs evolve.

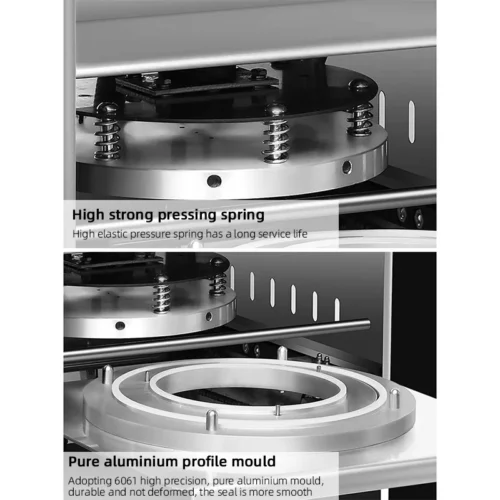

3. Material & Component Customization:

We offer custom manufacturing using a variety of materials to suit different environments and products. Stainless steel, aluminum, and food-grade plastics are just a few of the options available. We also provide custom component fabrication, from specific sensor placements to tailored nozzle designs.

4. Efficiency Enhancements:

Our engineering team can develop custom machinery aimed at maximizing throughput and minimizing downtime. Innovations such as automated changeover systems and precision control mechanisms are designed to streamline operations and increase productivity.

5. Industry-Specific Solutions:

Specialized industries such as pharmaceuticals, food and beverage, cosmetics, and electronics often require bespoke packaging solutions. We manufacture custom machinery that adheres to industry standards and regulations while ensuring optimal packaging performance.

6. Integration with Existing Systems:

Our custom machinery can be designed to seamlessly integrate with your existing production lines, ensuring smooth operation and minimal disruption. We provide detailed planning and execution for both new and retrofit installations.

Partner with PakTech Solutions for custom manufacturing options that precisely match your packaging needs, ensuring superior quality and operational excellence.

List Quality Control and The Manufacturing Process of "packaging machinery company"

Quality Control and The Manufacturing Process of a Packaging Machinery Company

#### Quality Control:

1. Incoming Material Inspection: All raw materials and components undergo rigorous inspections for compliance with specifications and standards.

2. In-Process Quality Checks: At various production stages, detailed checks are conducted using precise measurement tools to ensure parts meet design criteria.

3. End-of-Line Testing: Completed machinery is subjected to functional and performance tests to ensure they meet operational standards.

4. Calibration and Validation: Tools and equipment used in the production process are regularly calibrated and validated to maintain measurement accuracy.

5. Documentation and Traceability: Comprehensive records of inspections and tests are maintained, enabling traceability and accountability.

6. Continuous Improvement: Feedback loops from customers and ongoing internal audits drive continual enhancements in quality processes.

#### Manufacturing Process:

1. Design and Prototyping:

– Concept Development: Initial design concepts are developed based on customer requirements.

– Prototyping: Computer-aided design (CAD) software is used to create prototypes.

2. Material Sourcing:

– Vendor Selection: Materials and components are sourced from vetted suppliers with strong quality records.

– Inventory Management: Just-in-time inventory management ensures fresh, high-quality materials are available for production.

3. Fabrication:

– Machining: Precision machining processes like CNC milling and turning craft the components.

– Welding and Assembly: Skilled technicians weld and assemble the machinery, ensuring structural integrity and alignment.

4. Sub-Assembly:

– Component Integration: Key components such as motors, sensors, and control panels are integrated into sub-assemblies.

– Sub-Assembly Testing: Each sub-assembly is tested individually for functionality.

5. Final Assembly:

– System Integration: Sub-assemblies are combined to form the final machinery.

– Electrical and Software Installation: Integration of electrical systems and software ensures operational control.

6. Final Inspection and Testing:

– Operational Testing: Machines undergo thorough operational tests to ensure all functions work seamlessly.

– Packaging and Shipping: Finished machinery is carefully packed to prevent damage during transit and shipped to customers.

By adhering to stringent quality control measures and a systematic manufacturing process, a packaging machinery company ensures the delivery of reliable, high-performance equipment.

How to use "packaging machinery company"

If you are in the manufacturing or production industry, partnering with a packaging machinery company can significantly enhance your operational efficiency and product quality. Packaging machinery companies specialize in providing equipment and solutions tailored to packing various products, from food and beverages to pharmaceuticals and consumer goods.

To utilize a packaging machinery company effectively, follow these steps:

1. Identify Your Needs: Determine the type of packaging required for your products. This could be bottling, labeling, sealing, wrapping, or a combination of these processes.

2. Research Providers: Look for reputable packaging machinery companies with a proven track record. Check customer reviews, case studies, and their industry expertise.

3. Consultation: Engage in a consultation with the shortlisted companies. Discuss your specific requirements, production volume, and any special considerations like sustainability or automation.

4. Evaluate Solutions: Assess the machinery options presented. Consider factors such as cost, speed, ease of use, and maintenance requirements. Ensure that the machines comply with industry standards and regulations.

5. Customization: If standard solutions don’t meet your needs, inquire about custom machinery. Many companies offer tailored solutions to fit unique production lines.

6. Testing: Before full-scale implementation, test the machinery with your products to ensure compatibility and performance.

7. Training: Arrange for operator training. Proper training ensures your team can efficiently and safely use the equipment.

8. Installation and Support: Opt for companies that provide comprehensive installation services and ongoing technical support.

9. Maintenance: Regular maintenance is crucial. Choose a company that offers reliable after-sales service to keep your machinery in optimal condition.

By strategically leveraging a packaging machinery company, you can streamline your packaging processes, reduce downtime, and improve product presentation, ultimately enhancing customer satisfaction and operational profitability.

List Properties and Terms of "packaging machinery company"

A packaging machinery company specializes in the design, manufacture, and supply of machines used for packaging products. Below are key properties and terms relevant to such a company:

Properties:

1. Product Range: Includes machines for filling, sealing, wrapping, labeling, and cartoning.

2. Customization: Offers tailored solutions to meet specific client needs.

3. Materials Compatibility: Ability to work with various packaging materials like plastic, glass, metal, and paper.

4. Technology Integration: Incorporates advanced technologies such as automation, robotics, and IoT.

5. Regulatory Compliance: Adheres to industry standards like FDA, CE, and ISO certifications.

6. User Interface: Features intuitive controls for ease of operation.

7. Scalability: Capable of handling different production scales, from small batches to mass production.

8. Durability and Reliability: Ensures long-lasting operation with minimal downtime.

Terms:

1. Filling Machinery: Equipment used to introduce products into containers.

2. Sealing Machinery: Devices that close packages to secure contents.

3. Wrapping Machinery: Machines that wrap products for protection and presentation.

4. Cartoning Machinery: Equipment that forms, fills, and closes cartons.

5. Labeling Machinery: Machines for applying labels to packages.

6. Automation: Use of automatic equipment to streamline production.

7. Conveyor System: Mechanized movement of products between different stages of packaging.

8. Blister Packaging: A method of packaging using pre-formed plastic for protection.

9. Shrink Wrapping: A plastic film is wrapped around the product and shrink tightens with heat.

10. Foil Sealing: Sealing of containers using foil, often for airtightness.

11. Palletizing: Placement of finished packages onto pallets for transportation.

12. Serialization: Assigning unique identifiers to individual products or packages.

13. Secondary Packaging: Packing used to group primary packaged products.

14. Turnkey Solutions: Fully complete, ready-to-use packaging systems provided by the company.

15. ROI (Return on Investment): Measurement of investment effectiveness in machinery.

By understanding these properties and terms, stakeholders can better comprehend the operations and capabilities of a packaging machinery company.

List The Evolution history of "packaging machinery company"

The evolution of packaging machinery companies traces back to the industrial revolution when the need for efficient packaging solutions emerged prominently.

Early Beginnings (Late 19th Century):

The origins of packaging machinery began in the late 1800s with manual and semi-automatic machines designed to meet the growing demands of consumer goods. Innovations like the hand-operated candy wrapping machine and the mechanized canning process marked early milestones.

Early 20th Century:

The early 1900s saw the advent of more sophisticated machinery. Companies like Crown Cork & Seal Co. began producing bottle capping machines, and innovations in the paper and plastic industries ushered in automated wrapping and sealing techniques.

Mid 20th Century:

Post World War II, the packaging industry experienced significant advancements. The introduction of high-speed labeling machines, form-fill-seal machines, and advances in materials like cellophane and polyethylene transformed packaging processes. Companies like Hayssen and Bosch Packaging Technology became notable for their contributions to the sector.

Late 20th Century:

From the 1970s to the 1990s, computerization and robotics further revolutionized packaging. Enhanced automation allowed for intricate tasks like bottle filling, carton forming, and continuous sealing. Packaging companies increasingly focused on efficiency and precision, with pioneers like Tetra Pak leading the way in innovative designs for liquid packaging.

21st Century:

The 2000s onward saw an emphasis on sustainability and smart technology. Modern packaging machinery companies incorporate eco-friendly materials, energy-efficient machines, and IoT-enabled systems for real-time monitoring and predictive maintenance. Key players such as ProMach and Krones AG continue to shape the industry with cutting-edge solutions.

Recent Trends:

Today, digitalization, artificial intelligence, and Industry 4.0 technologies drive the evolution. The focus is on reducing waste, enhancing customizability, and improving overall efficiency in the packaging line.

The history of packaging machinery companies reflects continuous innovation aligned with technological advancements and market demands, shaping the way products are safely and efficiently delivered to consumers worldwide.

How to Select a Reliable packaging machinery company

Selecting a reliable packaging machinery company requires thorough consideration of several key factors:

1. Reputation and Experience: Opt for companies with a solid track record and longstanding history in the industry. Research their client reviews, testimonials, and case studies to gauge their reliability and expertise.

2. Quality and Technology: Ensure the machinery meets high-quality standards and incorporates the latest technology. Verify certifications (e.g., ISO) and inquire about their R&D efforts to understand their commitment to innovation.

3. Customization and Scalability: Choose a company that can tailor solutions to your specific needs and offers scalable machinery that can grow with your business.

4. Service and Support: Evaluate the company’s after-sales service, including warranty, maintenance, and training. Look for providers with a strong, responsive support system and easy access to spare parts.

5. Cost and Value: While price is important, balance it with the value offered. Consider long-term costs, including maintenance and energy efficiency, not just the initial investment.

6. Client References: Ask for references and contact their clients to gather firsthand feedback on their experiences and the performance of the machinery.

7. Compliance and Safety: Confirm that the machinery complies with industry standards and safety regulations. This ensures both legal compliance and operational safety.

8. Geographical Reach: If your business is international, ensure the company has a global presence or at least reliable international support.

9. Trial and Demonstration: Whenever possible, arrange for a trial or on-site demonstration to see the machinery in action and evaluate its compatibility with your operations.

Taking the time to methodically assess these factors will help you choose a reliable packaging machinery partner aligned with your business goals and operational needs.

List "packaging machinery company" FAQ

Certainly! Here’s a list of frequently asked questions (FAQ) for a packaging machinery company:

-

What types of packaging machinery do you offer?

We offer a wide range of packaging machines including filling machines, capping machines, labeling machines, form-fill-seal machines, carton sealers, and more. -

Can your machines be customized?

Yes, we provide customized solutions tailored to meet the specific requirements of your production line and product specifications. -

What industries do you serve?

Our packaging machinery caters to several industries including food and beverage, pharmaceuticals, cosmetics, chemicals, and consumer goods. -

Do you offer installation and setup services?

Yes, we provide comprehensive installation and setup services. Our team of experts ensures that your equipment is properly installed and operational. -

What kind of training do you offer?

We offer on-site training for your operators and maintenance staff to ensure they are well-equipped to handle the machinery safely and efficiently. -

Can you provide maintenance and repair services?

Yes, we offer ongoing maintenance and repair services to ensure that your machinery continues to operate smoothly. -

What is the lead time for delivery?

Lead times vary depending on the machine type and customization requirements. Typically, standard machines are delivered within 4-6 weeks, while customized solutions may take longer. -

Do you offer warranty on your machines?

Yes, all our packaging machinery comes with a warranty period that covers parts and labor. Specific terms and duration can be discussed at the time of purchase. -

How energy-efficient are your machines?

Our packaging machinery is designed to be energy-efficient, helping you reduce operational costs and minimize your environmental footprint. -

What are the payment terms?

Payment terms depend on the contract. Typically, a deposit is required upon order confirmation, with the balance due prior to delivery. -

Can I see a demonstration of your machines?

Yes, we can arrange a demonstration either at our facility or through a virtual demo. -

Do you provide technical support?

Absolutely, we offer 24/7 technical support to assist you with any issues or questions you may have.

This concise FAQ provides a quick overview of our offerings and services to help address common inquiries from potential customers.

Top 10 FAQ with answer about packaging machinery company for Buyer Sourcing from China

Absolutely, here are the top 10 FAQs with concise answers about sourcing packaging machinery from a company in China:

-

What types of packaging machinery do you offer?

We provide a wide range of packaging machines including filling machines, sealing machines, labeling machines, wrapping machines, and complete packaging lines tailored for various industries like food, beverage, pharmaceuticals, and cosmetics. -

Can you customize machines to fit specific requirements?

Yes, we offer customization services to align with your unique specifications, including machine dimensions, packaging speed, materials, and automation levels. -

How do you ensure the quality of your machinery?

Our machines are manufactured under strict quality control protocols, adhering to international standards (CE, ISO). We use high-grade materials and components, and each machine undergoes rigorous testing before shipment. -

What is the average lead time for manufacturing and delivery?

Typically, the manufacturing process takes about 30-60 days, depending on the machine’s complexity and customization. Shipping times vary based on the destination but usually range between 15-30 days. -

Do you provide installation and training services?

Yes, we offer comprehensive installation and onsite training services. Our engineers can visit your facility or provide remote support to ensure smooth setup and operation. -

What kind of after-sales support do you offer?

We provide various after-sales services including spare parts supply, maintenance, and 24/7 technical support via phone, email, or online. Extended warranties are also available. -

Can you handle large volume orders?

Absolutely, we have a robust production capacity to manage large-scale orders and ensure timely delivery without compromising quality. -

What payment terms do you accept?

We typically accept T/T (Telegraphic Transfer), L/C (Letter of Credit), and other negotiable terms based on the order specifics. -

How do you handle shipping and logistics?

We collaborate with reputable international logistics companies to manage shipping efficiently, ensuring safe and timely delivery of your machinery. -

Do you have references or case studies from previous clients?

Yes, upon request, we can provide references and detailed case studies from past clients across various industries to demonstrate our performance and reliability.

These FAQs cover essential aspects and help in building trust for potential buyers sourcing packaging machinery from China.