List Technical Parameters of "packaging machinery manufacturer"

Packaging machinery manufacturers offer a wide range of equipment designed to automate the packaging process for various industries. Some common technical parameters to consider when selecting a packaging machinery manufacturer include:

1. Capacity: This refers to the maximum output capacity of the packaging machinery in terms of units per minute or hour. It is essential to match the capacity of the machinery with the production requirements of the business.

2. Accuracy: Accuracy is crucial to ensure the precise measurement and placement of packaging materials on products. Look for machinery that offers high accuracy rates to avoid wastage and ensure consistent packaging quality.

3. Flexibility: Packaging machinery should be adaptable to a range of products and packaging materials. Look for equipment that can easily adjust to different sizes, shapes, and materials without the need for extensive retooling.

4. Speed: Packaging machinery should be able to operate at high speeds without compromising on accuracy or quality. Higher speeds can lead to increased productivity and efficiency in the packaging process.

5. Automation: Look for packaging machinery that offers advanced automation features such as programmable controls, sensors, and robotics. Automation can improve efficiency, reduce labor costs, and minimize errors in the packaging process.

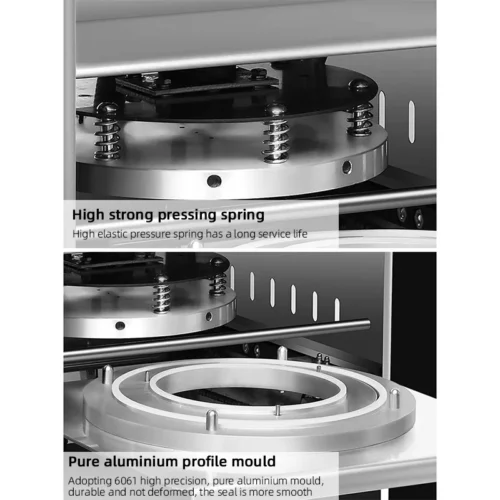

6. Durability: Packaging machinery should be built to withstand the rigors of continuous operation in a production environment. Look for equipment made from high-quality materials that are designed for long-term reliability and performance.

By considering these technical parameters when selecting a packaging machinery manufacturer, businesses can ensure they choose equipment that meets their specific production needs and delivers consistent, high-quality packaging results.

List Product features of "packaging machinery manufacturer"

Packaging machinery manufacturers offer a range of products with various features to meet the needs of different industries. Some common product features include:

1. Customization options: Packaging machinery manufacturers offer customization options to tailor the equipment to the specific needs of the client, which can include size, speed, and materials.

2. Versatility: Packaging machinery manufacturers provide machines that can handle a wide range of products, from food and beverages to pharmaceuticals and cosmetics, allowing businesses to package diverse items efficiently.

3. Automation: Many packaging machines come equipped with advanced automation features, such as programmable controllers and touch screen interfaces, to streamline the packaging process and reduce the need for manual labor.

4. Durability: Packaging machinery manufacturers create machines using high-quality materials that are durable and long-lasting, ensuring reliable performance and minimal downtime.

5. Safety features: Manufacturers prioritize safety by incorporating features like safety guards, emergency stop buttons, and sensors to protect operators and prevent accidents.

6. Energy efficiency: Packaging machinery manufacturers design machines with energy-efficient components and technologies to reduce energy consumption and lower operating costs for businesses.

7. Maintenance and support: Manufacturers provide comprehensive maintenance services and support to ensure that the equipment continues to operate smoothly and efficiently, minimizing downtime and maximizing productivity.

In conclusion, packaging machinery manufacturers offer a range of products with features like customization, versatility, automation, durability, safety, energy efficiency, and maintenance support to meet the unique needs of businesses in various industries. These features help businesses improve efficiency, reduce costs, and enhance their packaging processes.

List Application of "packaging machinery manufacturer"

1. Food packaging: Packaging machinery manufacturers play a crucial role in the food industry by providing equipment such as sealing machines, filling machines, and labeling machines. These machines help automate the packaging process, ensuring food products are properly sealed and labeled for retail distribution.

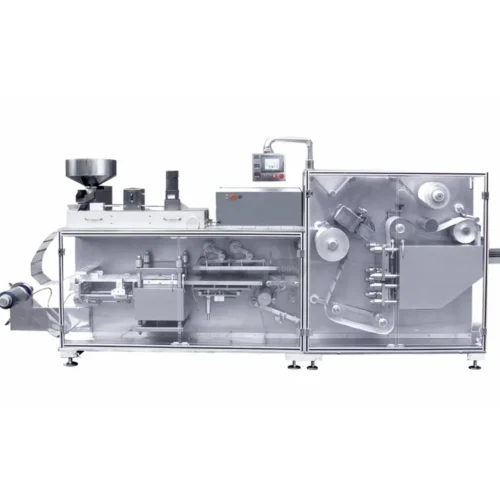

2. Pharmaceutical packaging: In the pharmaceutical industry, packaging machinery manufacturers supply equipment like blister packaging machines, bottle filling machines, and capping machines. These machines are essential for maintaining product integrity and ensuring compliance with industry regulations.

3. Cosmetics packaging: Packaging machinery manufacturers also cater to the cosmetics industry by producing equipment such as tube filling machines, jar filling machines, and labeling machines. These machines help cosmetic companies efficiently package their products in various types of containers.

4. Beverage packaging: Beverage companies rely on packaging machinery manufacturers for equipment like bottling machines, capping machines, and labeling machines. These machines ensure beverages are packaged safely and efficiently for distribution to consumers.

5. Personal care product packaging: Packaging machinery manufacturers also serve the personal care product industry by providing equipment like sachet filling machines, sachet sealing machines, and labeling machines. These machines help personal care companies package their products in convenient and attractive packaging.

Overall, packaging machinery manufacturers play a crucial role in various industries by providing innovative and efficient equipment for packaging products. Their technology helps companies streamline their packaging processes, improve product quality, and meet industry standards.

List Various Types of "packaging machinery manufacturer"

1. Filling Machines: These machines are used to accurately fill bottles, cans, pouches, and other containers with liquids, powders, or granular products. They can be gravity-fed, piston-driven, or equipped with a rotary filler to meet various production needs.

2. Wrapping Machines: These machines are designed to wrap products in a protective layer or cover for storage, transportation, or display. It includes stretch wrapping machines, shrink-wrapping machines, and vacuum sealing machines.

3. Labeling Machines: Labeling machines apply adhesive labels to products for identification, branding, or regulatory compliance. They can be automatic, semi-automatic, or fully automated to meet different labeling requirements.

4. Coding and Marking Machines: These machines are used to imprint expiration dates, batch codes, logos, and other information directly on products or packaging materials. They include inkjet printers, thermal transfer printers, and laser marking systems.

5. Cartoning Machines: Cartoning machines are used to erect, fill, and seal cartons for packaging products in bulk. They can be horizontal cartoners for high-speed production lines or vertical cartoners for manual or semi-automatic operation.

6. Sealing Machines: Sealing machines are used to secure the closure of packaging materials, such as bags, pouches, bottles, and boxes. They include heat sealers, induction sealers, and band sealers for different sealing applications.

7. Capping Machines: Capping machines are used to cap bottles, jars, and containers with screw caps, snap caps, or press-on caps. They can be automatic cappers, rotary cappers, or handheld capping tools for various cap sealing needs.

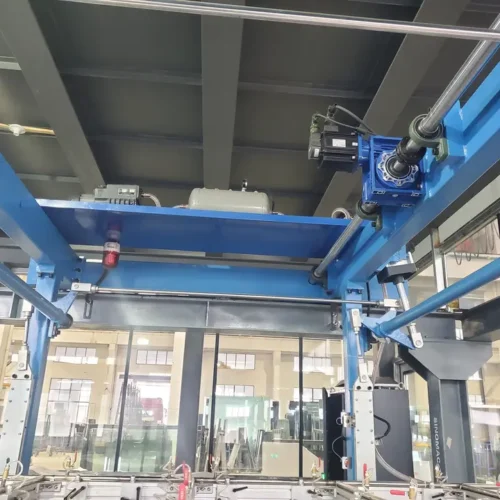

8. Conveying Systems: Conveying systems transport products between different packaging machinery, such as filling machines, labeling machines, and sealing machines. They include belt conveyors, roller conveyors, and automated transfer systems for smooth material handling in production lines.

Custom Manufacturing Options for packaging machinery manufacturer

As a packaging machinery manufacturer, it is essential to offer custom manufacturing options to meet the specific needs and requirements of your customers. By providing customized solutions, you can better serve a diverse range of industries and applications.

Some of the custom manufacturing options that you may consider offering include:

1. Customized machine design: Work closely with your customers to understand their unique packaging requirements, and develop a custom machine design that meets their specifications. This can include modifications to existing machines or the development of entirely new equipment.

2. Specialized packaging solutions: Offer specialized packaging solutions for industries with unique packaging challenges, such as pharmaceuticals, food and beverage, or cosmetics. This can involve the integration of specific features, such as cleanroom compatibility, tamper-evident sealing, or automated labeling.

3. Customized feeding and handling systems: Develop custom feeding and handling systems to accommodate a wide range of product shapes, sizes, and materials. This can include the integration of conveyors, robotics, and vision systems to optimize product flow and ensure accurate placement.

4. Integration of third-party equipment: Partner with other manufacturers to integrate third-party equipment, such as printers, labelers, or inspection systems, into your packaging machinery. This can provide your customers with a complete packaging solution that meets their specific production requirements.

5. Customized controls and automation: Offer customized control systems and automation solutions to streamline production processes and improve efficiency. This can include the development of custom software, HMI interfaces, and data tracking capabilities to enhance machine performance and operator convenience.

By offering custom manufacturing options, you can differentiate your packaging machinery company in a competitive market and provide your customers with tailored solutions that meet their unique packaging needs. This can result in increased customer satisfaction, repeat business, and a reputation for innovation and flexibility in the industry.

List Quality Control and The Manufacturing Process of "packaging machinery manufacturer"

Quality control in the manufacturing process of a packaging machinery manufacturer involves various stages to ensure the final product meets industry standards and customer requirements. This includes initial design and prototyping, material selection, production processes, assembly, testing, and final inspection.

The quality control begins with the design stage, where engineers analyze customer needs and requirements to create a detailed blueprint for the packaging machinery. Prototyping is then conducted to test the functionality and performance of the design before moving into full-scale production.

Material selection is a critical aspect of quality control as it directly impacts the durability and performance of the packaging machinery. High-quality materials are chosen based on their strength, durability, and suitability for the intended application.

During production, strict quality control measures are implemented to ensure each component is manufactured to precise specifications. This includes monitoring the machining, welding, and assembly processes to detect any defects or deviations from the design.

Assembly of the packaging machinery involves careful calibration of components to ensure proper functionality. Testing is conducted at various stages of assembly to verify performance and address any issues that may arise.

Final inspection is the last stage of quality control, where the finished packaging machinery is thoroughly examined for any defects or imperfections. This ensures that the product meets all quality standards before being shipped to the customer.

Overall, quality control is an essential part of the manufacturing process for a packaging machinery manufacturer to deliver reliable and high-performing products to their customers.

How to use "packaging machinery manufacturer"

A packaging machinery manufacturer is a company that specializes in designing, producing, and distributing machinery that is used in the packaging industry. These machines are essential for businesses that need a reliable and efficient way to package their products.

To utilize a packaging machinery manufacturer, businesses can research the various types of machines available and choose the one that best fits their needs. These machines can include equipment such as filling machines, sealing machines, labeling machines, and more.

When working with a packaging machinery manufacturer, businesses can expect to receive personalized attention and guidance on selecting the right machinery for their specific packaging requirements. Manufacturers often provide consultation services to help businesses understand their options and make informed decisions.

In addition to machinery selection, a packaging machinery manufacturer can also offer installation, training, and maintenance services to ensure that the equipment operates smoothly and efficiently. This can help businesses minimize downtime and increase productivity.

Overall, working with a packaging machinery manufacturer can help businesses streamline their packaging processes, improve product quality, and reduce costs. By partnering with a reliable manufacturer, businesses can stay competitive in the market and meet the growing demands of customers.

List Properties and Terms of "packaging machinery manufacturer"

Packaging machinery manufacturers are companies that design, produce, and sell equipment used in the packaging process of goods and products. These manufacturers provide a wide range of machinery that can automate various packaging functions, such as filling, sealing, labeling, and wrapping.

Some of the key properties and terms associated with packaging machinery manufacturers include:

1. Product Range: Packaging machinery manufacturers offer a diverse range of equipment, including filling machines, labeling machines, shrink wrap machines, carton sealers, and palletizers.

2. Customization: Manufacturers often provide custom solutions to meet the specific packaging needs of their customers. They may offer tailored equipment designs and features to optimize packaging efficiency.

3. Quality and Durability: Packaging machinery manufacturers focus on producing high-quality and durable equipment to ensure reliable and consistent performance in packaging operations.

4. Innovation: Manufacturers continuously strive to improve their machinery by incorporating the latest technological advancements, such as automation, robotics, and smart sensors.

5. Compliance: Manufacturers adhere to industry standards and regulations to ensure that their equipment meets safety, quality, and environmental requirements.

6. After-Sales Support: Manufacturers provide maintenance, repair, and technical support services to help customers maximize the performance and lifespan of their machinery.

7. Global Presence: Many packaging machinery manufacturers have a worldwide presence through sales, distribution, and service networks, catering to diverse industries and markets.

Overall, packaging machinery manufacturers play a crucial role in the packaging industry by providing efficient, reliable, and innovative equipment to meet the evolving needs of businesses in various sectors.

List The Evolution history of "packaging machinery manufacturer"

Packaging machinery manufacturers have significantly evolved over the years to meet the increasing demand for automated packaging solutions. In the early 20th century, manual packaging processes dominated the industry, with simple machines like bag sealers and hand-operated filling machines being the norm.

By the mid-20th century, advancements in technology led to the development of semi-automatic packaging machines, which improved efficiency and productivity in packaging operations. These machines were able to perform basic tasks like filling, sealing, and labeling with minimal human intervention.

In the late 20th century, the packaging industry witnessed a shift towards fully automated packaging solutions. Packaging machinery manufacturers began incorporating cutting-edge technologies such as robotics, sensors, and computer control systems into their machines. This allowed for increased speed, accuracy, and customization in packaging processes.

In the 21st century, packaging machinery manufacturers have continued to innovate and adapt to the changing demands of the market. The focus has shifted towards sustainability, with manufacturers developing eco-friendly packaging solutions that reduce waste and energy consumption. Additionally, the rise of e-commerce and the need for efficient packaging solutions for online retail has prompted manufacturers to develop specialized machinery for this growing segment.

Overall, the evolution of packaging machinery manufacturers can be characterized by a continuous drive towards automation, efficiency, and innovation to meet the evolving needs of the packaging industry.

How to Select a Reliable packaging machinery manufacturer

Selecting a reliable packaging machinery manufacturer is crucial for ensuring smooth operations and quality packaging solutions. To do so, consider the following factors:

1. Reputation: Look for a manufacturer with a solid reputation in the industry. Research their track record, customer reviews, and years of experience.

2. Quality of machinery: Inspect the quality of the machinery manufactured by the company. Look for certifications, such as ISO, CE, or others, to ensure compliance with industry standards.

3. Customization options: Choose a manufacturer that offers customization options to meet your specific packaging needs. This can include size, speed, and type of packaging machinery.

4. Customer support: Evaluate the manufacturer’s customer support services, including technical assistance, maintenance, and training. Prompt support can help in minimizing downtime.

5. Price and cost-effectiveness: Compare the prices of different manufacturers to find one that offers a good balance between quality and affordability. Consider long-term costs, such as maintenance and spare parts.

6. Innovation and technology: Select a manufacturer that invests in research and development to offer cutting-edge technology and innovative solutions for packaging needs.

7. Warranty and after-sales service: Ensure that the manufacturer provides a warranty for their machinery and offers reliable after-sales service for any issues that may arise.

By considering these factors, you can select a reliable packaging machinery manufacturer that meets your business requirements and ensures efficient and effective packaging solutions.

List "packaging machinery manufacturer" FAQ

1. What types of packaging machinery do you manufacture?

We specialize in manufacturing a wide range of packaging machinery, including form-fill-seal machines, labeling machines, shrink wrap machines, and carton sealing machines.

-

Can you provide customized packaging machinery solutions?

Yes, we offer customized packaging machinery solutions tailored to meet the specific needs of our clients. Our team of engineers and designers work closely with our clients to develop a solution that fits their unique requirements. -

Do you offer installation and training services for your packaging machinery?

Yes, we provide installation and training services for all our packaging machinery. Our team of experienced technicians will ensure that the machinery is installed correctly and train your staff on how to operate and maintain it. -

What kind of warranty do you offer on your packaging machinery?

We offer a comprehensive warranty on all our packaging machinery to provide our clients with peace of mind. Our warranty covers parts and labor for a specified period after the purchase. -

Can you provide ongoing technical support for your packaging machinery?

Yes, we offer ongoing technical support for all our packaging machinery. Our dedicated team of technical support specialists is available to assist with any questions or issues that may arise. -

How do I get a quote for your packaging machinery?

You can request a quote for our packaging machinery by contacting our sales team. They will work with you to determine your needs and provide you with a competitive quote for the machinery that best fits your requirements.

Top 10 FAQ with answer about packaging machinery manufacturer for Buyer Sourcing from China

1. What types of packaging machinery do you manufacture?

We manufacture a wide range of packaging machinery including filling machines, sealing machines, capping machines, labeling machines, and more. -

Are your packaging machinery products suitable for my industry?

Our packaging machinery products are highly versatile and can be customized to suit a variety of industries including food and beverage, pharmaceutical, cosmetics, and more. -

Can I get a sample of your packaging machinery before making a bulk purchase?

Yes, we can provide samples of our packaging machinery for testing before making a bulk purchase. -

Do you offer customization services for your packaging machinery?

Yes, we offer customization services for our packaging machinery to meet the specific needs and requirements of our customers. -

Can I visit your factory in China to see your packaging machinery production process?

Yes, we welcome customers to visit our factory in China to see our packaging machinery production process. -

What is the lead time for manufacturing and delivering packaging machinery products?

The lead time for manufacturing and delivering packaging machinery products may vary depending on the type and quantity of products ordered. We will provide you with an estimated lead time upon placing your order. -

Do you provide after-sales support for your packaging machinery products?

Yes, we provide after-sales support for our packaging machinery products including installation, training, and maintenance services. -

Can you provide references from other customers who have purchased your packaging machinery products?

Yes, we can provide references from other customers who have purchased our packaging machinery products upon request. -

What quality control measures do you have in place for your packaging machinery products?

We have strict quality control measures in place at every stage of the production process to ensure that our packaging machinery products meet the highest quality standards. -

What are your payment terms for purchasing packaging machinery products?

Our payment terms for purchasing packaging machinery products may vary depending on the order value and our agreement with the customer. We will provide you with our payment terms upon reaching a mutual agreement.