Overview of the Paper Cup Manufacturing Industry

The paper cup manufacturing industry has witnessed a significant transformation since its inception in the late 19th century. With the increasing demand for disposable and eco-friendly products, paper cups have become an integral part of our daily lives. From coffee shops to corporate events, they offer a convenient solution without compromising on environmental values.

China, as a manufacturing powerhouse, has played a pivotal role in catering to the global demand for paper cups. With advanced technology, state-of-the-art machinery, and a focus on sustainability, Chinese manufacturers have set high standards in the paper cup production arena.

Choosing the right paper cup manufacturer is crucial for businesses. Factors such as production capacity, technological advancements, customer service, and cost-effectiveness play a significant role in making an informed decision. In this guide, we'll explore the top manufacturers, their offerings, and tips for international buyers to ensure a seamless purchasing experience.

What are Paper Cups and Their Benefits?

Paper cups, as the name suggests, are cups made primarily from paper and often lined with plastic or wax to prevent liquid from leaking out or soaking through the paper. They have become an indispensable part of our daily lives, offering convenience and hygiene.

Benefits of Using Paper Cups:

- Eco-friendly: Paper cups are biodegradable and have a lesser environmental impact compared to plastic cups. With the increasing awareness about environmental conservation, many businesses are opting for paper cups.

- Convenience: They are lightweight, easy to stack, and disposable, making them perfect for events, offices, and cafes.

- Hygienic: Disposable paper cups are more sanitary as they are used only once, reducing the chances of contamination.

- Customization: Paper cups can be easily customized, making them an effective tool for branding and marketing.

Introducing PkgMach.com: Your Reliable Packaging Machine Manufacturer

PkgMach stands as a beacon of reliability in the packaging machine manufacturing industry. With its roots firmly planted in China, it has expanded its reach globally, ensuring businesses across the world have access to top-notch packaging solutions.

Key Highlights of PkgMach:

- Diverse Product Range: From salt packaging machines to rotary capping machines, PkgMach caters to a wide array of business needs.

- Commitment to Excellence: PkgMach's dedication transcends beyond mere selling. They ensure businesses not only get the best machines but also the right packaging solutions to thrive.

- Reputation: Their standing as a premier manufacturer ensures that buyers are making a sound and reliable investment.

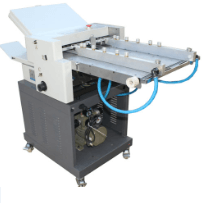

The Manufacturing Process of Paper Cup Machines

The manufacturing process of paper cup machines is a blend of precision, technology, and quality control. From the initial design phase to the final testing, every step is meticulously planned and executed to ensure the highest standards.

Steps Involved:

- Design & Blueprint: The process begins with a detailed design of the machine, keeping in mind the specific requirements and industry standards.

- Material Selection: High-quality materials are chosen to ensure durability and efficiency.

- Assembly: The machine parts are assembled with precision to ensure smooth functioning.

- Quality Control: Rigorous testing is conducted to ensure the machine meets the set standards.

- Final Inspection: Before shipping, a final inspection is done to ensure the machine is in perfect working condition.

Tips for International Buyers When Dealing with Chinese Suppliers

Engaging with suppliers from a different country, especially one as vast and diverse as China, can be a daunting task. However, with the right approach and knowledge, international buyers can ensure a smooth and beneficial collaboration.

Key Considerations:

- Research: Before finalizing a deal, conduct thorough research on the supplier. Check for reviews, testimonials, and any certifications they might have.

- Communication: Establish clear communication channels. Ensure that both parties understand the terms of the agreement, product specifications, and delivery timelines.

- Cultural Etiquette: Understanding and respecting cultural nuances can go a long way in building a strong business relationship.

- Visit the Factory: If possible, visit the supplier's factory. This gives a firsthand view of their operations, quality control measures, and overall work ethic.

- Payment Terms: Discuss and finalize payment terms in advance. Ensure there are no hidden charges or fees.

- After-sales Service: A good supplier will offer after-sales service. Ensure that this is part of your agreement.

FAQ Tips about Paper Cup Making Machine

What's the difference between Single PE Coated and Double PE Coated Machines?

Single PE Coated machines are designed for cups that require coating on one side, typically the inside. Double PE Coated machines, on the other hand, coat both the inside and outside of the cup, providing extra insulation and strength.

How does Ximenger Machinery ensure the quality of its machines?

Ximenger Machinery follows a rigorous quality control process, from the design phase to final testing. They also invest in continuous R&D to ensure their machines are technologically advanced.

What's the production capacity of Ximenger's machines?

The Single PE Coated Hot Drinks Paper Cup Forming Machine, for instance, has a production speed of 55-60pcs/min.

Are there any environmental certifications associated with the machines?

While specific certifications might vary, most reputable manufacturers ensure their machines meet environmental standards and have the necessary certifications.

How does PkgMach compare to other manufacturers in China?

PkgMach stands out for its commitment to quality, diverse product range, and global reputation. Their dedication to ensuring businesses thrive with the right packaging solutions sets them apart.

What are the payment terms and shipping options available?

Payment terms and shipping options vary based on the supplier and the specific agreement. It's essential to discuss and finalize these details in advance.

Can the machines be customized based on specific requirements?

Yes, most manufacturers, including Ximenger Machinery, offer customization options to meet specific business needs.

What's the warranty period for the machines?

Warranty periods vary, but a standard period is usually one year. It's crucial to clarify this with the supplier.

Are there any training or installation services provided?

Most reputable suppliers offer installation guidance and training to ensure smooth operation.

How to handle repairs or parts replacement during the machine's lifecycle?

Suppliers typically provide after-sales service, which includes repairs and parts replacement. It's essential to have a clear agreement regarding this.

The paper cup making machine industry, with China at its forefront, has seen significant advancements over the years. For businesses looking to venture into this domain or expand their operations, choosing the right machine and supplier is crucial. With thorough research, clear communication, and a focus on quality, businesses can ensure they make a sound investment that yields high returns.