The paper plate machine industry has witnessed significant growth over the years, with China emerging as a dominant player in the global market. As the demand for disposable tableware continues to rise, the need for efficient and reliable paper plate machines has become paramount.

Understanding the Paper Plate Machine

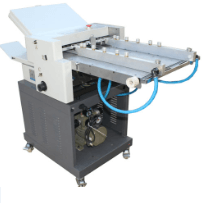

A paper plate machine is a specialized device designed to produce paper plates of various sizes and shapes. The core components include a mold, a hydraulic press, and a cutting mechanism. These machines are known for their efficiency, producing thousands of plates in a single hour.

Types and Applications of Paper Plate Machines

The versatility of paper plate machines is evident in the variety of models available in the market. Some machines are designed for high-speed production, while others focus on intricate designs and patterns.

- High-speed Machines: These are ideal for large-scale production, often used by big manufacturing units. They can produce thousands of plates per hour, ensuring that large orders are completed in a timely manner.

- Design-centric Machines: These machines prioritize design and aesthetics. They are equipped with advanced molding capabilities to produce plates with intricate patterns, suitable for high-end events or premium brands.

Applications of paper plate machines span across various sectors:

- Food and Catering: The most common use is in the food industry, where disposable plates are a staple. From street food vendors to upscale restaurants offering takeaway services, paper plates are widely used.

- Event Management: For events like weddings, parties, or corporate gatherings, disposable tableware is both convenient and practical. Paper plate machines that produce design-centric plates are especially popular in this sector.

- Personal Use: With the rise of DIY culture, many individuals invest in small-scale paper plate machines for personal projects or small-scale commercial ventures.

PkgMach.com: A Trusted Name in the Paper Plate Machine Industry

PkgMach.com has carved a niche for itself in the paper plate machine industry. With a focus on innovation and customer satisfaction, the company has consistently delivered top-notch products.

- Company Profile: Founded in [Year], PkgMach.com started as a small enterprise but has grown exponentially. Today, it's one of the leading suppliers of paper plate machines in China.

- Product Services: PkgMach.com offers a wide range of services, from machine installation to after-sales support. Their team of experts ensures that clients have a seamless experience, from purchase to production.

- Case Studies: Over the years, PkgMach.com has collaborated with various industries, showcasing their versatility. Their case studies highlight successful projects, emphasizing their commitment to excellence.

The Manufacturing Process: From Factory to Market

The manufacturing process of a paper plate machine is a blend of traditional craftsmanship and modern technology.

- Material Sourcing: Quality raw materials are sourced, ensuring the machine's durability and efficiency.

- Design and Engineering: Using advanced CAD tools, the machine is designed. Every component, from the hydraulic press to the mold, is crafted with precision.

- Assembly: Once all parts are ready, they are assembled. This stage involves rigorous quality checks to ensure that the machine operates flawlessly.

- Quality Assurance: Before the machine is shipped, it undergoes a series of tests. This ensures that the end-user receives a product that meets the highest standards.

The subsequent sections, as outlined earlier, can delve deeper into the user guide, questions for suppliers, and FAQs, ensuring a comprehensive overview of the paper plate machine industry.

User Guide: Operating the Paper Plate Machine

Operating a paper plate machine efficiently requires a thorough understanding of its components and functionalities. Here's a step-by-step guide:

- Installation and Setup:

- Choose a stable location with ample space for the machine.

- Ensure the power source matches the machine's requirements.

- Connect the machine to the power source and turn it on. Check for any unusual sounds or vibrations.

- Safety Precautions:

- Always wear safety gear, including gloves and protective eyewear.

- Ensure the workspace is free from any obstructions.

- Do not operate the machine with wet hands or in a damp environment.

- Operating the Machine:

- Load the paper roll onto the machine.

- Set the desired size and shape using the machine's control panel.

- Start the machine and monitor the production process. Ensure plates are being formed correctly.

- Maintenance and Troubleshooting:

- Clean the machine regularly to prevent paper dust accumulation.

- Lubricate moving parts as per the manufacturer's recommendations.

- If the machine malfunctions, refer to the user manual or contact the supplier for assistance.

Questions International Buyers Should Ask Chinese Suppliers

Engaging with suppliers, especially from a different country, requires due diligence. Here are some pivotal questions to ask:

- Company Verification: "Can you provide your company's registration and certification documents?"

- Product Quality: "What quality standards do your machines adhere to?"

- After-sales Service: "What kind of warranty and post-purchase support do you offer?"

- Customization: "Can the machines be customized as per specific requirements?"

- Bulk Pricing: "Do you offer discounts on bulk orders or long-term contracts?"

- Shipping and Delivery: "How do you handle international shipping, and what are the associated costs?"

- Client References: "Can you provide references or testimonials from international clients?"

FAQ Tips: Addressing Common Queries

- What is the average lifespan of a paper plate machine?

- With proper maintenance, a paper plate machine can last for several years, often up to 10 years or more.

- Can the machine handle different types of paper?

- Most machines are versatile and can handle various paper types, including thick cardstock and thin paper sheets.

- Is it environmentally friendly?

- Yes, as long as the paper used is biodegradable or recyclable, the plates produced are eco-friendly.

- How energy-intensive is the machine?

- Modern machines are designed to be energy-efficient, but exact consumption varies based on the model and usage.

- What's the return on investment for a paper plate machine?

- This depends on the scale of production and market demand. However, with the rising demand for disposable plates, ROI is generally favorable.

- Are there any training programs available for machine operation?

- Many suppliers, including PkgMach.com, offer training sessions for buyers to ensure smooth operations.

- How often does the machine require maintenance?

- Regular cleaning is advised, while thorough maintenance checks can be done every 6 months.

- What safety features are integrated into the machine?

- Modern machines come with safety shut-offs, emergency stops, and protective barriers to ensure user safety.

- Can the machine produce plates of different shapes and sizes?

- Yes, by changing the mold, the machine can produce plates of various shapes and sizes.

- Is it possible to get spare parts easily?

- Reputed suppliers usually have a stock of spare parts and can provide them as needed.

This comprehensive guide offers insights into the paper plate machine industry, ensuring potential buyers and users are well-informed and equipped to make the best decisions.