List Technical Parameters of “peanut coating machine”

The peanut coating machine is an essential piece of equipment used in the food processing industry for coating peanuts with various spices, flavors, and coatings. The following are some of the technical parameters of the peanut coating machine:

1. Production capacity: The production capacity of the peanut coating machine varies from one model to another, ranging from 50 kg to 500 kg per hour. The higher the capacity, the more peanuts can be coated in a shorter time.

2. Power consumption: The peanut coating machine requires electricity to operate, and the power consumption varies from one model to another. It ranges from 1.5 KW to 14 KW, depending on the capacity and features of the machine.

3. Material of construction: The peanut coating machine is typically constructed from stainless steel, which ensures durability, safety, and hygiene. Stainless steel is also easy to clean and maintain, making it a preferred choice for food processing equipment.

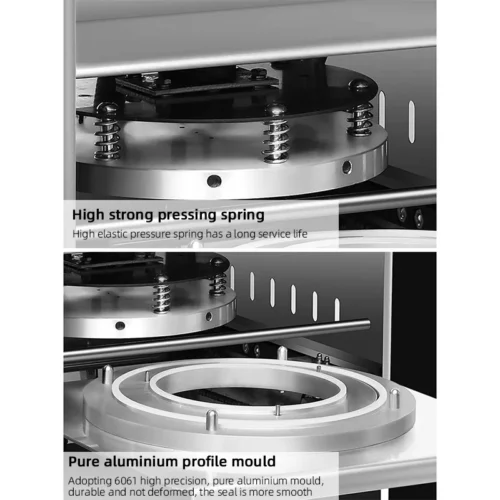

4. Coating drum size: The coating drum is an essential part of the peanut coating machine, and its size determines the amount of peanuts that can be coated at a time. The coating drum size ranges from 800 mm to 1400 mm in diameter and 400 mm to 800 mm in length.

5. Coating material: The peanut coating machine can be used to coat peanuts with a variety of materials, including flour, sugar, salt, honey, chocolate, and other spices. The coating material can be adjusted to achieve the desired flavor and texture.

6. Heating system: Peanut coating machines come with a heating system that is used to dry the peanuts after they are coated. The heating system can be electric or gas-powered, depending on the model.

7. Control system: The peanut coating machine is equipped with a control system that allows operators to adjust the speed, temperature, and other parameters necessary for optimal performance.

In conclusion, the peanut coating machine is a versatile piece of equipment that helps manufacturers produce tasty and flavorful coated peanuts. The technical parameters outlined above play a significant role in determining the performance and efficiency of the machine.

List Product features of “peanut coating machine”

The peanut coating machine is a versatile piece of equipment that has several features designed to optimize the peanut coating process. These features include:

1. High Capacity: This machine can process several kilograms of peanuts per hour, making it a perfect choice for factories or small businesses with high production requirements.

2. Adjustable Coating Thickness: This machine can adjust the thickness of coatings according to various requirements, allowing the user to experiment with different kinds of coatings to find the best one for their product.

3. Durable and Easy to Clean: Peanut coating machines are built to last and are made with high-quality materials that are resistant to rust and corrosion. They are also designed to be easy to clean, making maintenance a breeze.

4. Uniform Coating: This machine ensures that the coating applied to the peanuts is uniform, minimizing product inconsistencies and ensuring customers receive consistently high-quality products.

5. Versatile Coating Types: Peanut coating machines can accommodate different types of coatings such as sugar, chocolate, honey, and spice.

6. Industrial-grade Components: The peanut coating machine is built with robust and industrial-grade components that ensure its longevity and high performance for many years.

7. Easy to Operate: The user-friendly interface and simple controls make the machine easy to use, even for novice operators.

8. Energy Efficient: This machine uses energy-efficient technology, making it an eco-friendly and cost-effective option for businesses.

9. Safety Features: Peanut coating machines come with several safety features such as emergency stops and guards to prevent injuries while in operation.

10. Customizable: Peanut coating machines are customizable, and manufacturers can tailor them to meet specific production requirements to ensure maximum efficiency and productivity.

List Application of “peanut coating machine”

Peanut coating machines are versatile machines used in food production processes that involve coating peanut chips. The peanut coating machines can be used in many applications, including food processing factories, confectioneries, snack food factories, and many other industries. Here are some of the primary applications of peanut coating machines:

1. Confectionery production: Peanut coating machines are used in the production of confectioneries such as peanut butter, peanut candies, and peanut brittle. Peanut coating machines of different sizes can be used to coat the peanut chips with different types of coatings, including sugar, chocolate, or honey.

2. Snack food production: Peanut coating machines are used in the production of coated peanuts as a snack food. The machines can coat the peanuts with different flavors, spices, or coatings such as sugar, salt, or chili.

3. Pharmaceutical industry: Peanut coating machines are used in the pharmaceutical industry to coat small pills or capsules with a particular flavor or odor.

4. Pet food production: Peanut coating machines are used in the pet food industry to coat pet food with a variety of coatings, including vitamins, minerals, and other nutrients.

5. Agricultural industry: Peanut coating machines are used in the agricultural industry to coat seeds with pesticides to protect them from pests and diseases.

6. Industrial manufacturing: Peanut coating machines are used in the industrial manufacturing of machinery parts to create a protective coating to prevent rust or damage.

7. Chemical industry: Peanut coating machines can be used in the chemical industry to coat chemical compounds with a protective layer to prevent contamination.

In conclusion, the peanut coating machine has many applications in various industries, including food processing, confectionery production, pharmaceutical, pet food production, agricultural industry, industrial manufacturing, and the chemical industry. The flexibility of these machines makes them an essential tool in many manufacturing processes that require coating. The machines are easy to use, and they save time and labor costs significantly.

List Various Types of “peanut coating machine”

There are various types of peanut coating machines that are commonly used in the food processing industry. These machines can be classified based on their operating principle, size, and function. In this article, we will discuss some of the most popular types of peanut coating machines.

1. Drum Coating Machine – It is a type of coating machine that uses a rotating drum to coat peanuts with a thin layer of sugar syrup or starch. This machine is commonly used to produce caramelized or flavored peanuts.

2. Pan Coating Machine – This machine is similar to the drum coating machine, but instead of a drum, it uses a rotating pan. The pan is heated, and a liquid coating is added to the peanuts while they are being rotated in the pan.

3. Fluidized Bed Coating Machine – It is a machine that uses a continuous flow of air to fluidize the peanuts, and then a coating material is sprayed onto the surface of the peanuts as they are fluidized. The coated peanuts are then dried in the same machine. This machine is popularly used for coated peanuts and other snack foods.

4. Enrobing Machine – This machine is used for covering a layer of chocolate or other confectionery on peanuts. The peanuts are passed through a continuous flow of chocolate that coats the product evenly.

5. Dry Roasting Machine – It is a type of peanut coating machine that uses hot air to roast the peanuts. In this machine, the peanuts are coated with oil or other ingredients before being roasted.

These are some of the most popular types of peanut coating machines that are commonly in use in the food processing industry. Each machine has its own unique features and advantages, making it suitable for different applications in food processing.

List The Process of “peanut coating machine”

The peanut coating machine is used to coat peanuts with various flavors such as chocolate, sugar, and spice. The process of peanut coating machine involves several steps which are important to obtain perfectly coated peanuts.

The first step in the peanut coating machine is to clean the peanuts. The peanuts must be cleaned properly to remove any dirt or debris that could potentially affect the flavor of the final product.

After cleaning, the peanuts are then roasted in an oven to give them a crunchy texture and enhance their flavor. The roasting process gives the peanuts a rich and nutty taste that will be prominent in the final product.

Once the peanuts are roasted, they are then placed into the coating machine. The machine consists of a rotating drum that applies the coating mixture to the peanuts evenly. The coating mixture is usually made up of a sweet or savory ingredient such as chocolate or sugar.

As the drum rotates, the peanuts are coated with the mixture, and the excess mixture falls through the perforations in the drum. The rotation of the drum is also necessary to prevent the peanuts from clumping together.

The coated peanuts are then cooled and dried to remove any excess moisture. This is important because any moisture left within the coating could cause the peanuts to spoil quicker. Once dried, the coated peanuts are ready for packaging.

In conclusion, the peanut coating machine is a crucial component in the production of perfectly coated peanuts. The process involves cleaning, roasting, coating, and drying the peanuts to produce a delicious and crunchy snack. Through this process, the peanut coating machine provides a unique flavor experience to consumers.

How to use “peanut coating machine”

Peanut coating machines are used in the food industry to coat peanuts with a variety of flavors such as chocolate, sugar, honey, and spices, among others. They are easy to use and can produce large quantities of coated peanuts in a short time.

The first step is to prepare the peanuts by roasting or frying them until they are golden brown and cooked through. Once the peanuts are ready, they are placed into the coating machine, which has a large drum with a rotating paddle inside.

The coating material is then added into the drum containing the peanuts and rotated using the machine. The paddle stirs the nuts continuously, ensuring that the coating material is evenly distributed throughout the nuts.

The amount of coating used will depend on the recipe being followed. However, it is essential not to overload the drum as it could cause uneven distribution of the coating and damage the machine’s paddle.

Once the peanuts are evenly coated, they are transferred to a cooling tray to dry out. This helps to prevent the peanuts from clumping together and sticking to one another.

It is essential to clean the machine thoroughly after use to avoid contamination of flavor in the subsequent sessions. Peanut coating machines generally come with cleaning instructions, but it is important to follow the manufacturer’s instructions for optimal use of the machine.

In conclusion, peanut coating machines are a great addition to any food industry that needs large quantities of coated peanuts. They are easy to use, produce consistent results, and are time-saving.

List Properties of “peanut coating machine”

Peanut coating machines are devices used to coat peanut with different coatings such as chocolate, sugar, flour, etc. These machines come in different sizes and designs depending on the type of coating it is intended to apply. The following are some of the properties of peanut coating machines:

1. Material Quality: The materials used in making these machines are usually stainless steel, which is durable, resistant to corrosion, and easy to clean.

2. Automatic Control System: The machines are equipped with an automatic control system that can be programmed to control the temperature, speed, and coating thickness.

3. Efficiency: These machines are designed to coat peanuts with different coatings quickly and uniformly. This saves time, labor, and ensures consistent quality.

4. Easy to Operate: Peanut coating machines are simple to operate, with easy-to-use controls and clear procedures that make them user-friendly.

5. Versatility: These machines can coat peanuts with different coatings, including chocolate, sugar, flour, and more. They can also handle different types of nuts.

6. Safety: Peanut coating machines are designed with safety features to ensure that the operator is safe while using the machine.

7. Easy to Maintain: These machines are easy to maintain, with simple cleaning procedures and low maintenance costs.

8. Durability: Peanut coating machines are made of high-quality materials that are durable and resistant to wear and tear.

9. Customization: Manufacturers of peanut coating machines can customize the machines to meet the specific requirements of customers.

In conclusion, peanut coating machines are essential devices in the food processing industry. These machines are designed to coat peanuts with different coatings quickly, efficiently, and uniformly. Their properties include material quality, automatic control system, efficiency, ease of operation, versatility, safety, easy maintenance, durability, and customization.

List “peanut coating machine” FAQ

1. What is a peanut coating machine?

A peanut coating machine is a specialized machine used in food processing to coat peanuts with various substances such as sugar, chocolate, and seasonings.

2. What are the benefits of using a peanut coating machine?

A peanut coating machine can help to improve the texture and flavor of peanuts by coating them evenly and in a controlled manner. It also helps to speed up the production process and reduce labor costs.

3. How does a peanut coating machine work?

A peanut coating machine has a rotating drum that tumbles peanuts while a coating material is applied. The machine may also have a heating or cooling system to help the coating material adhere to the peanuts.

4. What types of coating materials can be used in a peanut coating machine?

Common coating materials include sugar, chocolate, honey, and spices such as curry and cumin.

5. What factors should be considered when using a peanut coating machine?

The type of peanut being coated, the desired thickness of the coating, and the type of coating material being used are all important factors to consider. Additionally, proper cleaning and maintenance of the machine is crucial to ensure food safety and prevent contamination.

6. Can a peanut coating machine be used for other types of nuts?

Yes, a peanut coating machine can be used for other types of nuts such as almonds, cashews, and walnuts.

7. How much does a peanut coating machine cost?

The cost of a peanut coating machine can vary depending on the size, capacity, and features of the machine. Prices can range from a few thousand dollars to tens of thousands of dollars.

8. Where can I purchase a peanut coating machine?

Peanut coating machines can be purchased from specialized food processing equipment manufacturers or through online marketplaces. It is important to research the different options and choose a reputable supplier.