Introduction to Perfect Binding Machines

Perfect binding machines have revolutionized the printing and publishing industry, offering a sleek and durable solution for binding books, catalogs, and magazines. Unlike traditional binding methods that use staples or stitches, perfect binding employs adhesive to bind pages together, resulting in a clean and professional finish.

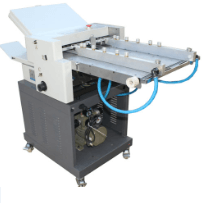

What is a Perfect Binding Machine? A perfect binding machine is a device used to bind books and publications using a method where the pages and cover are glued together at the spine. This results in a square spine that you see on most modern soft-cover books. The “perfect” in perfect binding refers to the clean, perfect edge created, not the perfection of the binding method itself.

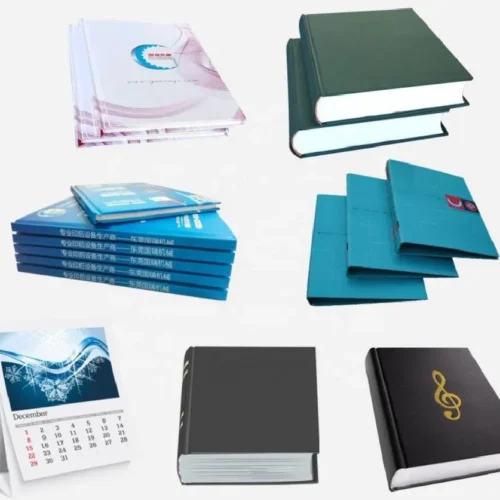

Importance in the Printing and Publishing Industry In the competitive world of publishing, presentation matters. Perfect binding provides a neat, professional appearance, making it a preferred choice for authors, publishers, and businesses alike. Whether it’s a novel, a company report, or a glossy magazine, perfect binding offers a high-quality finish that stands out on the shelf.

Types and Applications of Perfect Binding Machines

Perfect binding machines come in various models, each designed to cater to specific binding needs. Understanding the different types and their applications can help businesses make informed decisions.

Different Models and Their Specific Uses

- Desktop Models: Ideal for small to medium-sized businesses or educational institutions, these machines are compact and can handle moderate binding volumes.

- Industrial Models: Designed for large-scale operations like publishing houses, these machines can handle high volumes and offer faster binding speeds.

- Hybrid Models: These machines combine the features of both desktop and industrial models, offering versatility in binding capacities.

Industries and Sectors That Benefit the Most

- Publishing Houses: From novels to academic journals, perfect binding gives a professional finish that readers appreciate.

- Educational Institutions: For binding research papers, thesis documents, and other academic materials.

- Corporate Sector: Annual reports, company catalogs, and other corporate publications often use perfect binding for a sleek appearance.

- Print Shops: Offering binding services to a variety of clients, from students to local businesses.

Customization and Services Offered by PkgMach.com

PkgMach.com, a renowned name in the machinery industry, offers tailored solutions for businesses looking for perfect binding machines.

Tailored Solutions for Businesses

- Custom Design: Based on specific business needs, PkgMach.com offers custom-designed binding machines that cater to unique requirements.

- Integration with Existing Systems: The machines can be integrated with existing production lines, ensuring seamless operations.

After-Sales Services and Support

- Training: Comprehensive training sessions to ensure that users are well-acquainted with the machine’s operations.

- Maintenance and Repairs: Dedicated support for maintenance and any required repairs, ensuring the machine’s longevity.

- Parts Replacement: Ready availability of genuine parts for replacements, if needed.

Manufacturing Process: From Concept to Completion

The manufacturing of a perfect binding machine is a meticulous process that involves precision, expertise, and a commitment to quality. China, with its advanced manufacturing capabilities, has been at the forefront of producing these machines.

Steps in the Manufacturing Process

- Design and Blueprint Creation: Engineers draft a detailed design of the machine, considering factors like size, capacity, and functionality.

- Material Selection: High-quality metals and components are chosen to ensure the machine’s durability and efficiency.

- Machining and Assembly: Parts are machined to exact specifications and then assembled. This includes the installation of electrical components, the binding mechanism, and the adhesive system.

- Quality Control: Rigorous testing is conducted to ensure the machine operates flawlessly. This includes checking the binding quality, machine speed, and safety features.

- Packaging and Dispatch: Once approved, the machine is packaged securely and dispatched to the buyer, with all necessary installation and operational guidelines.

Operational Guidelines: Getting the Best Out of Your Machine

To ensure the longevity and optimal performance of the perfect binding machine, users must adhere to certain operational guidelines.

Setting Up the Machine

- Ensure the machine is placed on a stable surface, away from moisture and direct sunlight.

- Check all electrical connections and ensure they are secure.

- Load the adhesive and ensure it’s of the recommended quality.

Using the Machine

- Always start with a test run, binding a few sample books to ensure the settings are correct.

- Adjust the machine settings based on the thickness and size of the book being bound.

- Ensure the adhesive is applied evenly and that the binding is secure.

Maintenance Tips

- Clean the machine regularly to remove any adhesive residue.

- Check the electrical components and ensure they are functioning correctly.

- Lubricate moving parts periodically to prevent wear and tear.

Questions International Buyers Should Ask Chinese Suppliers

When sourcing a perfect binding machine from China, it’s essential to ask the right questions to ensure you’re getting a quality product.

- What certifications does your machine have?

- Can the machine be customized to our specific requirements?

- What is the warranty period, and what does it cover?

- Do you offer training on how to operate the machine?

- How do you handle repairs or part replacements?

FAQ Tips about Perfect Binding Machines

- What’s the difference between perfect binding and other binding methods?

- Perfect binding uses adhesive to bind pages, resulting in a clean, square spine, unlike methods like spiral or saddle-stitch binding.

- How long does the adhesive take to dry?

- Most modern machines use quick-drying adhesives that set within minutes.

- Can the machine handle different paper types and sizes?

- Yes, most machines are versatile and can be adjusted to handle various paper specifications.

- Is the binding durable?

- Perfect binding is known for its durability, making it ideal for books and publications that undergo regular handling.

- How often does the machine require maintenance?

- With regular cleaning and periodic checks, the machine can operate efficiently with minimal maintenance.