The beverage industry has witnessed a significant transformation over the years, with advancements in technology and machinery playing a pivotal role. Among the various machines utilized in the production process, the PET bottle filling machine stands out as a crucial component. This machine ensures that beverages are efficiently filled into PET bottles, ready for distribution and sale.

China, known for its manufacturing prowess, has emerged as a leading player in the production of these machines. With a blend of advanced technology, skilled workforce, and competitive pricing, Chinese companies have catered to the global demand effectively. One such renowned company is PkgMach.com, which has carved a niche for itself in the realm of PET bottle filling machines.

Features and Benefits

The PET bottle filling machine is not just about its specifications; its features and benefits make it stand out in the competitive market:

- Three-in-One Functionality: The machine seamlessly integrates rinsing, filling, and capping processes. This integration ensures efficiency, reduces manual intervention, and minimizes the chances of contamination.

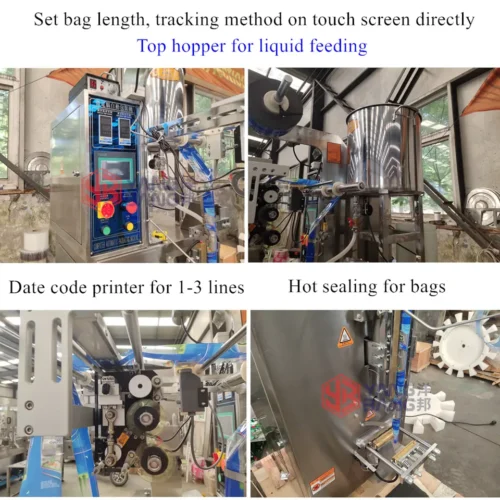

- High Automation: Equipped with a SIEMENS PLC control and touchscreen, the machine offers a high degree of automation. This feature ensures precision, reduces human errors, and enhances the overall production speed.

- Energy Efficiency: In today's world, where sustainability is paramount, this machine is designed to consume less power without compromising on performance.

- Long Service Life: Built with robust materials and designed for continuous operation, the machine promises a long service life. Its design also ensures easy maintenance, reducing downtime and ensuring consistent production.

Types and Applications

The PET bottle filling machine's versatility is evident in its adaptability to various beverage types and production scales. Let's explore the different models and their specific applications:

- Beverage Type Adaptability:

- Carbonated Drinks: Specialized machines ensure that carbonated beverages are filled without losing their fizz. This requires precision and a controlled environment to maintain the carbonation levels.

- Fruit Juices: Machines designed for juices often come with features that ensure minimal exposure to air, preserving the freshness and taste of the juice.

- Dairy Products: Dairy-based beverages require strict hygiene standards. The machines designed for this purpose ensure a sterile environment during the filling process.

- Pure Water: With the increasing demand for bottled water, machines optimized for water filling prioritize speed and accuracy.

- Custom Solutions: Recognizing that every beverage production line might have unique requirements, many manufacturers, including PkgMach.com, offer custom solutions. This ensures that businesses get a machine tailored to their specific needs.

Production Process and Factory Insights

The manufacturing of a PET bottle filling machine is a meticulous process, ensuring every unit meets the highest standards:

- Design and Blueprinting: The process begins with a detailed design, considering the machine's specifications, features, and the intended application. Advanced software tools aid in creating a virtual prototype.

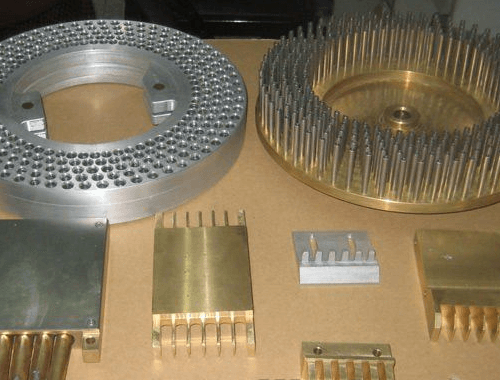

- Material Selection: Using high-quality materials like SUS304 or SUS316L ensures the machine's durability and longevity. The choice of material also plays a crucial role in maintaining hygiene standards.

- Assembly and Quality Control: Once all parts are manufactured, the assembly process begins. Every stage of assembly undergoes rigorous quality checks, ensuring the machine's optimal performance.

- Testing: Before shipping, every machine undergoes extensive testing. This ensures that it operates flawlessly under real-world conditions.

Why Choose a China-based Company and Supplier?

China's dominance in the manufacturing sector is well-established. When it comes to PET bottle filling machines:

- Competitive Pricing: Chinese manufacturers, given their scale of operations and local sourcing of materials, can offer competitive prices without compromising on quality.

- Expertise: With years of experience, companies like PkgMach.com have honed their skills, ensuring every machine meets global standards.

- Customization: Recognizing the diverse needs of the global market, Chinese suppliers often offer extensive customization options, ensuring every client gets a machine tailored to their requirements.

- After-sales Service: Beyond the product, after-sales service plays a crucial role. From installation guidance to maintenance support, Chinese suppliers ensure a holistic client experience.

Steps to Operate the PET Bottle Filling Machine

Operating a PET bottle filling machine requires a blend of technical knowledge and adherence to safety protocols. Here's a step-by-step guide:

- Setup and Initialization: Begin by ensuring the machine is correctly positioned and all parts are securely fastened. Power on the machine and initialize the PLC control system.

- Loading the PET Bottles: Depending on the machine's design, bottles may be loaded manually or automatically. Ensure they are correctly aligned on the conveyor belt.

- Setting the Parameters: Using the touchscreen interface, set the desired parameters such as filling volume, speed, and other relevant settings.

- Starting the Filling Process: Once everything is set, initiate the filling process. The machine will automatically rinse, fill, and cap the bottles.

- Monitoring and Quality Control: Continuously monitor the filling process. Ensure there are no leaks, and the filling volume is consistent. Periodic quality checks are crucial.

- Shutdown and Cleanup: After the production run, shut down the machine following the manufacturer's guidelines. Clean all parts that come in contact with the beverage to maintain hygiene.

Questions International Buyers Should Ask Chinese Suppliers

When sourcing a PET bottle filling machine from China, it's essential to ask the right questions:

- Certifications: Does the supplier have the necessary certifications that attest to the machine's quality and safety standards?

- Customization Options: Can the machine be tailored to specific requirements, and what are the associated costs?

- Training and Support: Does the supplier offer training for operating the machine? What about after-sales support and maintenance services?

- Warranty: What does the warranty cover, and for how long? Are extended warranties available?

FAQ Tips about PET Bottle Filling Machine

- How often does the machine require maintenance? Regular checks every three months and a comprehensive annual review are recommended.

- Can the machine handle different PET bottle sizes? Most machines are adjustable and can accommodate various bottle sizes.

- What's the energy consumption of the machine? This varies based on the model, but modern machines are designed for energy efficiency.

- How long is the machine's lifespan? With proper maintenance, these machines can last for 10-15 years.

- Is there a provision for integrating additional modules in the future? Many machines are modular, allowing for future upgrades.

- What safety features are in place? Features like emergency stop buttons, overload protection, and safety locks are standard.

- How does the machine ensure accurate filling? Advanced sensors and automation ensure consistent and precise filling.

- Are spare parts readily available? Reputable suppliers, like PkgMach.com, ensure a steady supply of genuine spare parts.

- What are the shipping and installation costs? This varies based on location and the supplier's policies.

- Can the machine be integrated with other production line equipment? Most machines are designed for seamless integration with existing production lines.

In conclusion, the PET bottle filling machine is an indispensable asset for beverage producers. With advancements in technology and the expertise of suppliers like PkgMach.com, businesses can ensure efficient, consistent, and high-quality production. Whether you're a small enterprise or a large-scale manufacturer, investing in the right machine can significantly impact your bottom line.