List Technical Parameters of "pickle packing machine"

A pickle packing machine is an industrial equipment designed for packing pickles or other pickled products into jars, bottles, or other containers. The equipment typically includes several technical features that enable the efficient and accurate packaging of the products. These features include:

1. Automated filling and capping: The machine is equipped with an automated filling and capping system that can accurately and quickly fill containers with pickles and seal them with caps or lids.

2. Adjustability: A good pickle packing machine should be adjustable to cater to various products, container sizes, and output rates. This means that it should have easy-to-adjust settings to ensure that the correct portion of pickles is dispensed into each container.

3. High Capacity: A good pickle packing machine should have a high production capacity to ensure reliable and efficient packaging. The capacity should be in line with customer needs and should also offer room for future expansion.

4. Consistency: The machine should ensure consistent product output, packaging, and labeling of the products. This is essential for customer satisfaction and improving the brand’s reputation.

5. Easy to clean and maintain: A good pickle packing machine should have a design that is easy to clean and maintain. The machine should have easily removable components that can aid in cleaning and maintenance.

6. Hygiene: The machine’s components should be made of food-grade materials that are easy to clean, sanitize, and do not contaminate the pickled products.

7. Quality control: The machine should have a built-in quality control system that can quickly detect any errors in the packaging process and fix them promptly.

8. Versatility: A good pickle packing machine should be versatile and capable of packing different types of pickled products and various container sizes.

In conclusion, a good pickle packing machine should offer high capacity, consistency, adjustability, hygiene, and versatility. Additionally, the machine should be easy to clean and maintain while also having a quality control system to ensure that the packed products meet the set standards.

List Product features of "pickle packing machine"

A pickle packing machine is a specialized piece of equipment that is designed to automate the entire process of packing pickles into jars, bottles, or other packaging containers. Most pickle packing machines are designed to handle high volumes of pickles at once, making the process faster, more efficient, and less labor-intensive.

The following are some of the key features of a typical pickle packing machine:

1. High-speed pickling: The machine is capable of processing pickles at a high rate of speed. It can efficiently and quickly pack large numbers of pickles into jars, bottles or other packaging containers.

2. Automated pickling process: A pickle packing machine is designed to automate the entire process. It can cap and label the jars once the pickles have been packed into them. This not only speeds up the overall process but also reduces the risk of human errors.

3. Adjustable filling speed: The machine offers the flexibility of adjusting the filling speed to accommodate different types of pickles.

4. Accurate filling quantity: Most pickle packing machines have a digital filling quantity feature that ensures that each jar is filled with a specific amount of pickles, ensuring consistency and reducing waste.

5. Low waste and spillage: These machines have been designed to handle pickles without damaging them, preventing waste and spillage. Any excess pickles or juice are collected by the machine, which can then be reused for future batches.

6. Efficient cleaning: A good pickle packing machine is easy to clean and requires minimal maintenance. The materials used to design the machines are impervious to corrosion, rust, and dirt, ensuring a long-lasting and reliable machine.

Overall, a pickle packing machine is an essential piece of equipment for any food manufacturer that deals with pickles. By automating the packing process, businesses can reduce labor costs, increase productivity, and ensure quality control in their products.

List Application of "pickle packing machine"

The pickle packing machine is a specialized machine designed to efficiently pack pickles in jars and other containers. It comes with advanced technology that simplifies the packaging process and enhances productivity. The machine has various applications in different settings, ranging from homes to manufacturing facilities. Here are some of its crucial applications:

1. Food industry - The pickle packing machine is commonly used in the food industry to pack pickles in large quantities. The machine can be utilized in food processing plants, supermarkets, and restaurants to eliminate manual labor and increase efficiency.

2. Home use - The pickle packing machine can be used in homes to process homemade pickles. It helps to simplify the packaging process, save time, and achieve professional results.

3. Processing plants - Pickle packing machines are ideal for processing plants that produce pickles in massive quantities. With the machine, the production process becomes more efficient and faster compared to manual packaging.

4. Beverage industry - The pickle packing machine is used in the beverage industry to package pickles in jars for sale. The machine improves productivity and enhances the quality of packaging.

5. Supermarkets - Pickles are common items in supermarkets. Therefore, a pickle packing machine can be installed in these facilities to enhance the packaging of the products. It ensures consistent packaging and saves time.

6. Export markets - The pickle packing machine is an essential tool for export markets. The machine ensures that pickles are packaged in a way that preserves their quality during transport to different parts of the world.

7. Medical industry - The pickle packing machine is used in the medical industry, particularly in research and development laboratories. It can be used to pack and store laboratory samples for research and testing purposes, ensuring that they are safe, secure, and well-preserved.

In conclusion, the pickle packing machine has many applications in different settings. It plays a significant role in enhancing the efficiency and effectiveness of the packaging process, regardless of the industry or market. Its use saves time, labor, and guarantees consistent packaging, thus enhancing product quality and market appeal.

List Various Types of "pickle packing machine"

Pickle packing machines are designed to help manufacturers pack pickles swiftly and safely. These machines help prevent contamination, enhance freshness and quality, and offer cost-effectiveness. Here are various types of pickle packing machines:

1. Pickle Filling Machine

This is a type of machine that helps with filling pickles into jars. The machine is designed to fill jars with a pre-determined quantity of pickles, thus ensuring uniformity of product.

2. Pickle Capping Machine

Pickle capping machines are built to work in combination with filling machines. These machines help to affix caps on jars after filling pickles. These machines are highly efficient, easy to operate, and help increase overall productivity.

3. Pickle Labelling Machine

These machines help with the application of labels on pickle jars. They are highly automated and can be customized to fit the specific requirements of a manufacturer.

4. Pickle Sealing Machines

These machines are designed to seal pickle jars after filling with pickles. They help to maintain the freshness and quality of pickles by preventing air and moisture from entering the jars. They come in different models, designs, and speeds to suit various production needs.

5. Pickle Packaging Machine

This type of machine is designed to package pickles after filling, capping, and sealing into jars. Pickle packaging machines come in various models, including vertical form fill seal machines, horizontal form fill seal machines or VFFS, and HFFS machines.

6. Pickle Frying and Roasting Machines

These machines are used to fry or roast pickles before packaging. They are designed to ensure the pickles are properly cleaned, sliced, and seasoned before frying or roasting.

7. Pickle Drying Machines

This type of machine helps remove excess moisture from pickle slices or pieces before packaging. It helps to increase the shelf life of pickles by preventing the growth of mold and bacteria due to excess moisture.

In conclusion, pickle packing machines are crucial tools for the pickle manufacturing industry. Whether it is filling, sealing, packaging, labeling, frying, or drying, there is a machine for every step of the process to ensure quality and precision.

List The Process of "pickle packing machine"

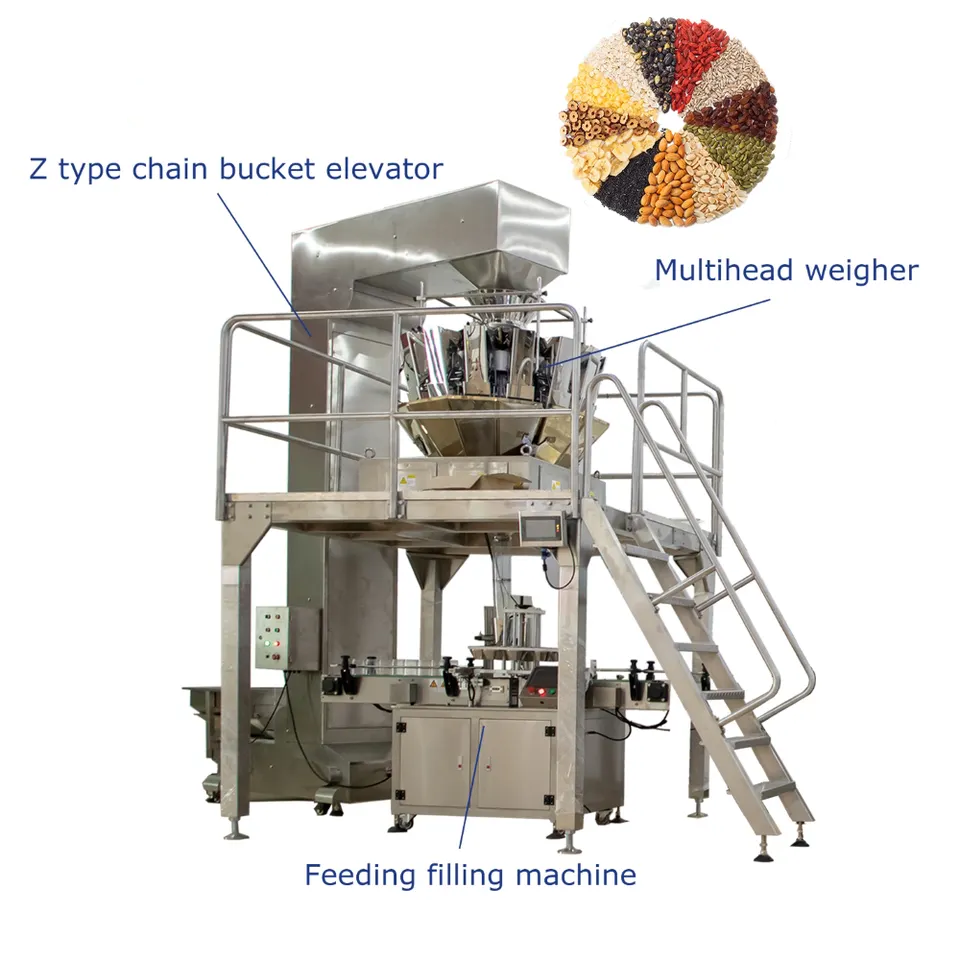

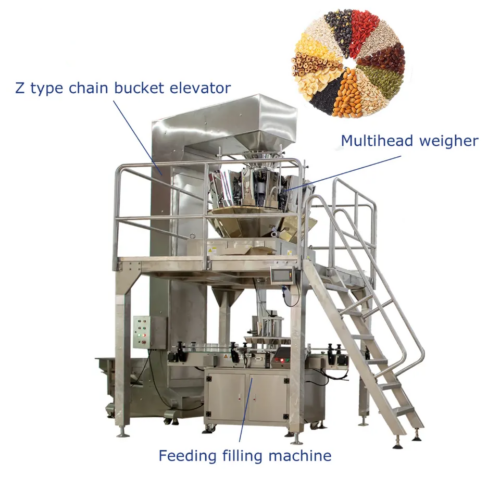

The process of pickle packing machine begins by filling the hopper with pickles. The hopper is usually situated above the main conveyor belt or feeding system. Here, the pickles are checked to ensure that they are of the required size and quality. After this, the pickles are weighed using an automated weighing system to ensure that each package contains the same amount of pickles.

Once the pickles are weighed, they are then transported to the packaging chamber where they are loaded into the packing tubes. The packing tubes are designed to hold a set weight of pickles and are usually made of stainless steel or food-grade plastic. The tubes are spaced out on the conveyor belt to allow for efficient loading.

Once the pickles are loaded into the packing tubes, they are then vacuum-sealed to remove any air from the packaging. This is done to increase the shelf-life of the pickles and to prevent spoilage. The vacuum sealing system is usually connected to the packaging chamber.

After vacuum sealing, the packages are labeled and coded for identification. The labeling system is usually automated and can print different types of information on the package, including the weight, expiry date, and other relevant details.

Finally, the packaged pickles are stored in cartons or crates for transportation. The cartons or crates are loaded onto a pallet and transported to the storage area. The storage area is usually temperature-controlled to ensure that the pickles remain fresh until they are delivered to the customers.

In conclusion, the pickle packing machine is an efficient and automated process that helps to increase the speed and accuracy of pickle packaging. The process involves weighing, loading, vacuum sealing, labeling, and storing the pickle packages in a temperature-controlled area.

How to use "pickle packing machine"

A pickle packing machine is a specialized piece of equipment that is used to fill jars or containers with pickles. The machine can be used in a variety of different settings, including food production facilities, restaurants, and other commercial kitchens. Using a pickle packing machine can help to improve the speed and efficiency of the pickling process, while also ensuring consistent quality in every jar.

To use a pickle packing machine, the first step is to prepare the pickles. This typically involves washing and slicing the cucumbers, and then placing them in a vinegar and spice brine. The pickles should marinate in the brine for several days or weeks to achieve the desired flavor and texture.

Once the pickles are ready, they can be loaded into the pickle packing machine. The machine typically has a conveyor belt system that feeds the pickles into a filling station. At the filling station, the machine uses a piston mechanism to dispense the brine into the jars or containers. The pickles are then sealed with a lid or cap, and the jars or containers can be labeled and packaged for shipment.

Some pickle packing machines are fully automated, meaning that they can perform all of these steps without manual intervention. Other machines may require some manual input, such as loading the jars onto the conveyor belt or adjusting the settings on the machine.

Overall, using a pickle packing machine can help to streamline the pickling process and improve the quality and consistency of the finished product. It's important to select a machine that is appropriate for your specific needs and production volume, and to follow proper safety and sanitation procedures when working with food products.

List Properties of "pickle packing machine"

A pickle packing machine, also known as a pickling machine, is a highly specialized piece of equipment that is designed to package pickled vegetables, fruits, and other similar products. It can handle a variety of jar sizes depending on the machine, and can pack single or multiple bags or pouches. The following are some of the most notable properties of a pickle packing machine:

1. High Efficiency: A pickle packing machine is designed to operate at high speeds, with some models able to pack over 60 jars per minute. This makes it an ideal choice for large-scale processing facilities that require high throughput rates.

2. Versatility: Some pickle packing machines come with multiple filling heads that allow for the simultaneous packing of multiple jars at once, making them capable of handling different products and jar sizes.

3. Precision Packaging: The machine will accurately measure and pack a specific amount of product into each jar or pouch. This ensures uniformity in the finished product, and minimizes waste.

4. Minimal Downtime: A quality pickle packing machine is robustly engineered with durable parts and components, allowing it to run for longer periods with minimal maintenance.

5. Customizable Packages: The pickle packing machine can perform a variety of sealing techniques, which provides the flexibility to produce different types of packages such as bags, jars, bottles, and pouches, with smooth and tight seals.

6. Ease of Cleaning: The machine is made from easily cleanable materials such as stainless steel, which makes it highly sanitary and ideal for food processing operations that have strict hygiene requirements.

In conclusion, a pickle packing machine is an essential piece of equipment for food processing companies that supply pickled products to the market. Its outstanding properties such as high efficiency, versatility, precision, minimal downtime, customizable packages, and ease of cleaning make this machine a worthy investment for businesses involved in the food industry.

List "pickle packing machine" FAQ

1. What is a pickle packing machine?

A pickle packing machine is a piece of equipment used to automatically fill jars or containers with pickles or other preserved foods.

2. How does a pickle packing machine work?

The machine works by filling jars or containers with pickles or other preserved foods using an automated process. The jars are fed into the machine, filled with pickles, and then sealed.

3. What types of pickles can be packed with a pickle packing machine?

A pickle packing machine can be used to pack a variety of pickles, including dill pickles, bread and butter pickles, sweet and spicy pickles, and more.

4. What are the benefits of using a pickle packing machine?

Using a pickle packing machine can automate the process of filling and sealing jars, making it faster and more efficient. This can help to save time and reduce labor costs.

5. What is the capacity of a pickle packing machine?

The capacity of a pickle packing machine can vary depending on the specific machine, but most machines can pack several hundred jars per hour.

6. Can a pickle packing machine be customized to fit specific needs?

Yes, many pickle packing machines can be customized to fit specific needs. This can include adjusting the filling speed, changing the size of jars or containers, and more.

7. How do pickles stay fresh when packed with a pickle packing machine?

Pickle packing machines often use a vacuum seal to help preserve the freshness of the pickles. This seal helps to prevent air and bacteria from getting in, which can cause the pickles to spoil.

8. What are the maintenance requirements for a pickle packing machine?

Maintenance requirements can vary depending on the specific machine, but most machines require regular cleaning and occasional repairs or replacements of parts.

9. Are pickle packing machines easy to use?

Most pickle packing machines are designed to be user-friendly and easy to operate. However, training may be required for new users to ensure proper operation and safety.

10. Where can I purchase a pickle packing machine?

Pickle packing machines can be purchased from a variety of manufacturers and suppliers. It is important to research and compare options before making a purchase to ensure that the machine meets your specific needs and budget.