Secondary Packaging Machinery - Bag-in-Bag Packaging Machine

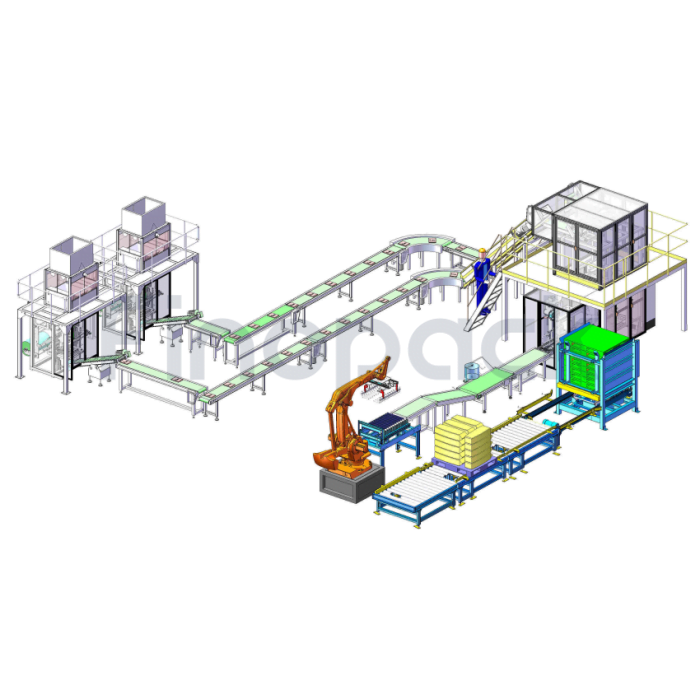

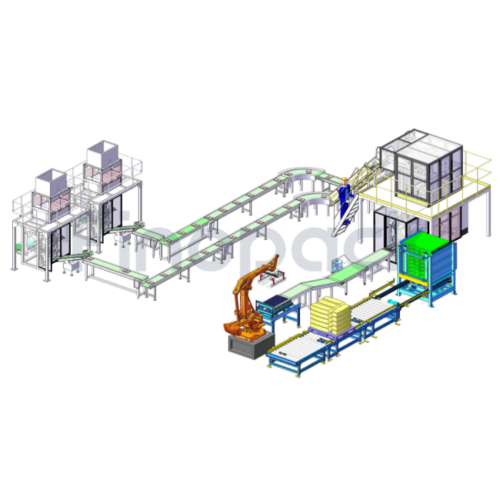

Secondary packaging machinery, specifically the Bag-in-Bag Packaging Machine, refers to equipment that handles the product's primary packaging before proceeding to the outer packaging stage. This automated process involves loading products from a vertical packaging machine into a woven bag and sewing the package based on specified requirements such as arrangement form and quantity. The secondary packaging production line typically involves tasks like transferring small bags into larger bags, placing small bags into boxes, labeling, marking, boxing, and palletizing.

The secondary packaging production line for soft bags primarily focuses on tasks like placing small bags into large bags (including laminated film bags, single film bags, or woven bags) or placing small bags into cartons and automatically stacking them.

| Model | Type of Big Bag | Packaging Scope | Packaging Speed | Form of Arrangement |

|---|---|---|---|---|

| FP1200/1500 | Pillow bag, gusset bag | 150-5000 bagged products | 6-8 for big bags | Horizontal single or double-row grouping |

| (Formed by roll film) | ||||

| FP2-1 | Prefabricated woven bag, | 150-5000g bagged products | 6-8 for big bags | Horizontal single or double-row grouping |

| Kraft bag, Paper-plastic bag | ||||

| etc. |

Packaging Range: 150g - 1000g sachet products

Packaging Materials: Paper bag, woven bag (lined with PP/PE film)

Packing Speed: 5-15 woven bags/min, 40-100 pouches/min (speed may vary according to products)

Arrangement Form: Single silo baiting, single row laying, double silo baiting, double row laying

Compressed Air: 0.5-0.7MPa, gas 0.8 m3/min

Features

- Fully automated packing process including bag feeding, opening, counting, filling, moving output, and sewing

- User-friendly touch screen control unit for easy operation, specification changes, and maintenance

- Customizable arrangement forms to meet various customer needs

Working Process

Sackets → Horizontal conveyor → Double slope conveyor → High-speed conveyor → Bag counting machine → Automatic bag feeding machine → Auto sewing machine → End woven bag putout

Applications

This unit is extensively used for packaging powder and granule products such as sugar, rice, washing powder, salt, seeds, milk powder, etc. It comprises components like a double-layer inclined conveyor, high-speed conveyor, counting and sorting machine, woven bag automatic packaging machine, sewing machine, and product conveyor.

Factory Gallery

Images are available for viewing in the attached related posts.

Related Posts:

- Heavy Bag Packaging Machine

- 50 kg Bag Packing Machine

- Vacuum Packing Machine

- 25kg Open Mouth Bagging Machine for Powder

- 25kg Open Mouth Bagging Machine for Granule

- Automatic 25kg Bagging Machine