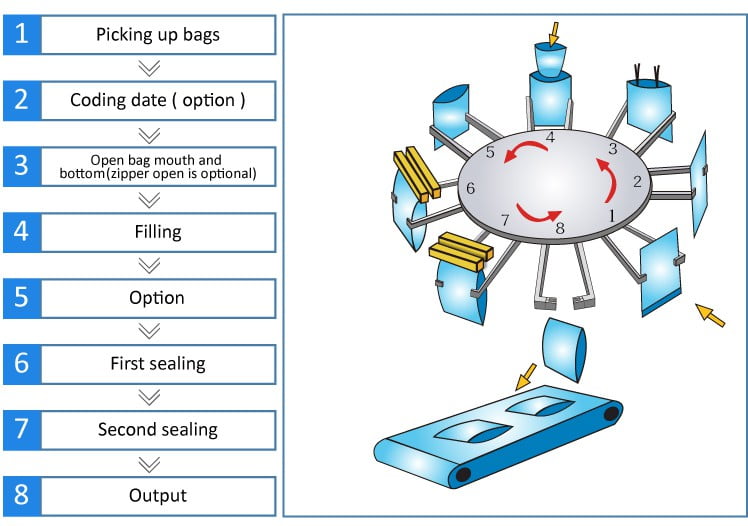

The Rotary Packing Machine unit comprises a packaging machine, work platform, finished product conveyor, linear scale, cup filler, or multihead weigher mechanism with Z type elevator. This equipment is designed for handling granular products like grains, chips, cookies, puffed food, peanuts, chilies, dry fruits, frozen fruits, pasta, beans, chia seeds, gum, gourmet powder, granular drugs, capsules, seeds, condiments, sugar, candies, chicken essence, melon seeds, nuts, pesticides, and fertilizers.

| Technical Specifications Model : | FP6-200 | FP6-250 | FP8-200 | FP8-320 | FP10-200 |

|---|---|---|---|---|---|

| Working Position | Six-working position | Six-working position | Eight-working position | Eight-working position | Ten-working position |

| Pouch Material | Laminated film | Laminated film | Laminated film | Laminated film | Laminated film |

| Pouch Pattern | Stand-up & zipper bag | Stand-up & zipper bag | Stand-up & zipper & 3-side sealing & 4-side sealing bag | Stand-up & zipper & 3-side sealing & 4-side sealing bag | Stand-up & zipper bag |

| Pouch Size | W:150-260mm L:150-350mm | W:200-330mm L:150-450mm | W:60-200mm L:150-380mm | W:200-320mm L:100-400mm | W:130-250mm L:120-360mm |

| Speed | 10-50 pouches/min | 10-50 pouches/min | 40-60 pouches/min | 10-30 pouches/min | 6-55 pouches/min |

| Weight | 1350KGS | 1500KGS | 1200KGS | 1400KGS | 1000KGS |

| Voltage | AC380V±10%, 3Phase50HZ | AC380V±10%, 3Phase50HZ | AC380V±10%, 3Phase50HZ | AC380V±10%, 3Phase50HZ | AC380V±10%, 3Phase50HZ |

| Total Power | 3.0KW | 3.0KW | 2.5KW | 2.5KW | 3.5KW |

| Compress Air | Air consumption 0.6m³/min | Air consumption 0.6m³/min | Air consumption 0.4m³/min | Air consumption 0.4m³/min | Air consumption 0.5m³/min |

| Bag Open | Vacuum open | Vacuum open | Vacuum open | Vacuum open | Vacuum open |

| Alarm Situation | 1. No bag no material, no sealing 2. Overload alarm 3. Low-pressure alarm |

Features:

- Easy to operate with an advanced PLC from Germany Siemens.

- Equipped with a user-friendly man-machine interface incorporating a touch screen and electric control system.

- Automatic checking function to prevent errors like no pouch, pouch open error, no fill, and no seal.

- Safety features include machine stop at abnormal air pressure and heater disconnection alarm.

- Easy to clean and maintain, with parts in contact with materials made of stainless steel.

Applications:

This machine can be used for a variety of solid and granular products.

- Solid Species: candy, peanuts, green beans, pistachios, cookies, cakes, pickles, etc.

- Granule Species: grains, drugs, capsules, seeds, sugars, nuts, fertilizers, etc.

Additional Features:

The machine can be customized with additional functions based on bag specifications and production requirements, including tong material stations, exhaust systems, vibration mechanisms, and more.

Factory Gallery: (Images not provided in this text)