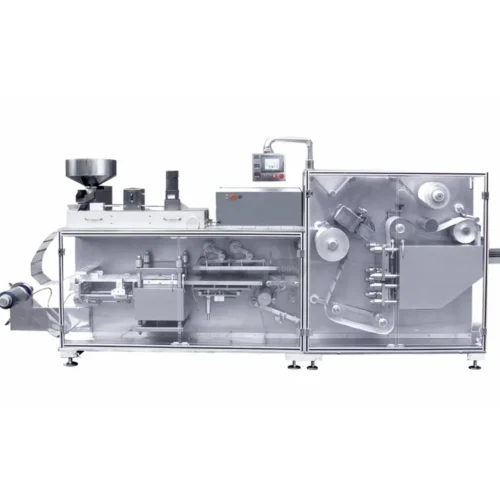

Understanding Sachet Packaging Machines

Sachet packaging machines have revolutionized the packaging industry, offering a compact and efficient solution for packing a variety of products. These machines are designed to automatically fill and seal sachets with precision, ensuring consistent product quality and presentation.

Customization: The Key to Meeting Unique Business Needs

One of the standout features of sachet packaging machines is their ability to be customized. Whether it's the logo on the sachet or the packaging material used, suppliers like PkgMach.com offer a range of customization options to meet the unique needs of every business.

The manufacturing of sachet packaging machines is a meticulous process that ensures the highest level of precision and efficiency. Here's a brief overview:

- Design and Blueprinting: Before the actual manufacturing begins, a detailed design of the machine is created. This includes the layout, size, and positioning of each component. Modern CAD tools are employed to visualize and test the design virtually.

- Material Selection: The primary materials used in these machines are stainless steel and high-grade plastics. These materials are chosen for their durability, resistance to corrosion, and suitability for food and chemical packaging.

- Assembly: Once all parts are fabricated, the assembly process begins. Each component, from the PLC to the motors, is carefully installed in its designated position.

- Quality Control: After assembly, each machine undergoes rigorous testing. This ensures that it operates smoothly, fills sachets accurately, and seals them perfectly.

- Customization: Depending on client requirements, the machine might undergo further customization. This could include branding, adjusting machine settings for specific sachet sizes, or integrating additional features.

Using the Sachet Filling Machine: A Step-by-Step Guide

Operating a sachet filling machine is a systematic process. Here's a basic guide:

- Setup: Ensure the machine is clean and positioned on a flat surface. Connect it to the power source and switch it on.

- Loading the Packaging Material: Insert the roll of packaging material into the designated slot.

- Filling Mechanism: Depending on the product (liquid, powder, granules), set up the appropriate filling mechanism.

- Setting the Machine: Using the control panel, set the desired sachet size, filling quantity, and sealing type.

- Start the Operation: Once everything is set, start the machine. It will automatically fill and seal the sachets.

- Regular Checks: Periodically check the machine to ensure that sachets are being filled and sealed correctly.

- Shutdown and Cleaning: After the operation, switch off the machine and clean it thoroughly to ensure it's ready for the next use.

Questions International Buyers Should Ask Chinese Suppliers

When sourcing sachet packaging machines from China, it's essential to ask the right questions:

- Certifications: Does the supplier have the necessary certifications that attest to the machine's quality and safety standards?

- Customization Options: What customization options are available, and at what cost?

- After-sales Support: What kind of support does the supplier offer post-purchase? This includes warranty, maintenance, and spare parts availability.

- Training: Does the supplier provide training on how to operate and maintain the machine?

- Shipping and Delivery: What are the shipping costs, and how long will delivery take?

Why Choose PkgMach.com as Your Trusted Supplier?

PkgMach.com stands out in the industry for several reasons:

- Experience: With years in the industry, PkgMach.com understands the nuances of packaging machinery.

- Quality Assurance: Every machine undergoes stringent quality checks to ensure top-notch performance.

- Custom Solutions: PkgMach.com offers tailored solutions to meet individual business needs.

- Global Reach: With a vast network of logistics partners, PkgMach.com ensures timely delivery worldwide.

FAQ Tips about Sachet Packaging Machine

What materials can the sachet packaging machine handle? The machine is versatile and can handle a variety of materials, including plastics, laminates, and foil, ensuring optimal packaging for different products.

How long does it take to set up the machine for operation? Initial setup, especially for first-time users, might take a couple of hours. However, with experience, the setup time can be reduced significantly.

Is there any specific training required to operate the machine? While the machine is designed to be user-friendly, initial training is recommended to understand its functionalities thoroughly. Most suppliers, including PkgMach.com, offer comprehensive training sessions.

What safety features are integrated into the machine? The machine comes with multiple safety features, including emergency stop buttons, overload protection, and alarms for irregularities in operation.

How energy-efficient is the sachet packaging machine? Modern sachet packaging machines are designed with energy efficiency in mind. They consume minimal power, reducing operational costs.

Can the machine handle multiple sachet sizes simultaneously? While the machine can handle various sachet sizes, it's typically set to one size at a time for consistency. However, switching between sizes is a straightforward process.

What's the average lifespan of a sachet packaging machine? With proper maintenance and care, a sachet packaging machine can last for several years, often beyond a decade, depending on usage intensity.

How do I troubleshoot common issues with the machine? Most machines come with a detailed manual that outlines common issues and their solutions. For complex problems, it's recommended to contact the supplier or manufacturer.

Are there any environmental considerations with the machine's operation? Yes, it's essential to ensure that the packaging materials used are recyclable or biodegradable, reducing environmental impact.

How does the machine ensure airtight sealing of sachets? The machine employs heat or ultrasonic sealing mechanisms to ensure that each sachet is airtight, preserving the freshness and quality of the product inside.