List Technical Parameters of “salt packaging machine”

Salt packaging machines are specifically designed to package and seal salt in various packaging formats. The technical parameters of salt packaging machines include their speed, accuracy, capacity, and versatility. A typical salt packaging machine has an output range of 10 to 80 bags per minute.

The two main types of salt packaging machines are vertical form-fill-seal (VFFS) machines and horizontal form-fill-seal (HFFS) machines. The former utilizes a vertical motion to form, fill, and seal the bags, whereas the latter uses a horizontal motion. The choice of machine depends on the packaging format, the type of salt, and the required output.

The technical parameters of salt packaging machines include the following:

1. Bag size: Salt packaging machines can accommodate bags of varying sizes, ranging from small sachets of 2g to large bags of 50kg.

2. Bag type: Salt packaging machines can produce various bag types, such as pillow bags, gusseted bags, and quad bags.

3. Filling accuracy: Salt packaging machines must ensure accurate filling of salt to avoid under or over-filling the bags. The accuracy is determined by the type of feeding system and the weighing technology used.

4. Sealing system: The sealing system must be reliable to prevent salt from spilling during transportation. The sealing technology used includes heat-seal, ultrasonic sealing, or band sealing.

5. Machine control: Salt packaging machines have advanced control systems that monitor the entire packaging process. These systems regulate the bagging process, temperature, pressure, and other parameters.

6. Material for packaging: Salt packaging machines use different materials for packaging, such as paper, plastic, and aluminum foil. The choice of material depends on the packaging format, the type of salt, and the storage environment.

7. Safety features: Salt packaging machines have safety features that prevent accidents, such as emergency stop buttons, interlocks, and safety covers.

In conclusion, salt packaging machines have evolved over the years to meet the increasing demand for packaged salt. The technical parameters of these machines ensure reliable, efficient, and safe packaging of salt in various formats.

List Product features of “salt packaging machine”

A salt packaging machine is a specialized equipment designed to package salt into varying sizes and shapes of bags. The machine has several features that enable it to perform its primary function of packaging salt efficiently. Some of the notable product features of a salt packaging machine include:

1. Bagging Speed: The salt packaging machine is designed to operate at high speeds. It can package salt in bags at a rate of up to several hundred bags per minute. This feature ensures a high level of productivity, and it can be customized to meet the specific needs of the manufacturer.

2. Bagging accuracy: The machine has high accuracy in bagging salt. It ensures that each bag has the correct weight of salt. This feature is critical in ensuring that consumers receive the right amount of salt, and it helps to minimize waste.

3. Bag Types: The salt packaging machine can package salt in various bag types, such as flat bottom bags, stand-up pouches, and gusseted bags, among others. This feature allows manufacturers to customize their packaging to fit their specific needs and preferences.

4. Touch Screen Display: The salt packaging machine has an intuitive touch screen display that enables operators to monitor the machine’s performance and make necessary adjustments. This feature ensures that the machine operates efficiently, and it increases productivity.

5. Low-maintenance: The machine is designed to be low-maintenance, making it easy to operate and maintain. It has minimal moving parts, and the packaging materials are easy to replace.

6. Safety Features: The salt packaging machine has several safety features, such as emergency stop mechanism, overcurrent protection, and overload protection. These features ensure that the machine operates safely and minimize the risk of accidents.

7. Material Compatibility: The machine is compatible with different packaging materials, such as laminated film, PE film, and paper, among others. This feature ensures that manufacturers have multiple options for packaging their salt.

In summary, the salt packaging machine is an essential tool for salt manufacturers. It has numerous features that ensure a high level of productivity, accuracy, and safety. The machine’s design enables it to package salt in different bag types and materials, making it a versatile tool for salt packaging.

List Application of “salt packaging machine”

1. Food Industry – The food industry requires packaging machines to pack edible products such as salt in a hygienic and convenient manner. The salt packaging machine can be used to pack salt in various quantities and sizes, including small sachets or large bags. This machine prevents contamination, preserves the quality of the salt, and enhances shelf life.

2. Agricultural Industry – Agricultural salt is used to enhance soil fertility, control weed, and support the growth of crops. The salt packaging machine is designed to handle the large volumes of salt required for agricultural purposes. The machine packages the salt in durable bags that can withstand storage and transportation.

3. Chemical Industry – The chemical industry uses salt in various chemical processes, including the production of chlorine and caustic soda. The salt packaging machine can package salt that is used as raw material or as a final product. The machine can handle different types of salt, including rock, sea, and table salt.

4. Pharmaceutical Industry – Salt is used in various pharmaceutical processes, including the formulation of IV saline solutions, cleaning of medical equipment, and preservation of vaccines. The salt packaging machine can package salt in different sizes and quantities needed for various pharmaceutical applications.

5. Water Treatment Industry – Salt is used in water softening, the regeneration of ion exchange resins, and in the treatment of water that is used in boilers and cooling systems. The salt packaging machine can package salt in the required quantities needed for these applications.

6. Animal Feed Industry – Salt is added to animal feed as a source of sodium and chlorine, which are important for animal health and growth. The salt packaging machine can package the salt that is used in animal feed in different sizes and quantities needed for different types of animals.

Overall, the salt packaging machine is a versatile piece of equipment that is essential for many industries that rely on salt as a raw material or final product. The machine contributes to the efficiency, accuracy, and quality of the packaging process, ensuring that these industries can produce and distribute quality products to their customers.

List Various Types of “salt packaging machine”

Salt packaging machines are used to pack salt in various types of packaging such as pouches, bags, sachets, jars, cans, and cartons. The different types of salt packaging machines include the following:

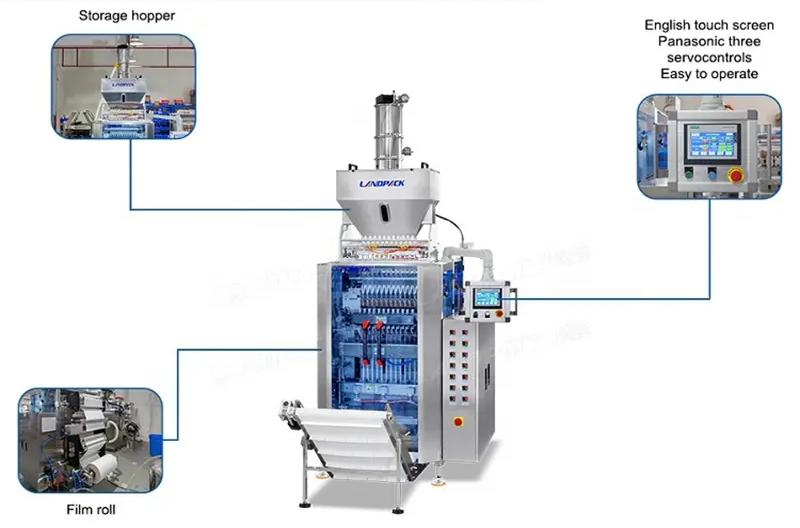

1. Vertical form fill seal machines- These machines form bags from a roll of film, fill the bags with salt, and seal them.

2. Auger filling machines- These machines fill salt into containers by using an auger screw to measure and dispense the salt.

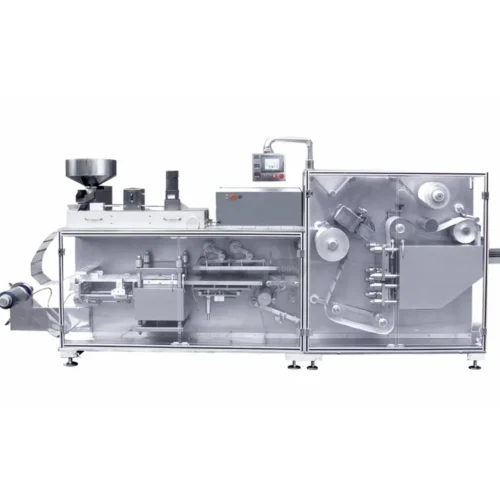

3. Horizontal flow wrap machines- These machines are used to wrap salt in a film, which forms a sealed bag around the salt.

4. Volumetric cup filling machines- These machines dispense salt into containers using cups of a predetermined volume.

5. Gravity feed machines- These machines are used for dispensing powdered salt into containers from a hopper using gravity.

6. Automatic bagging machines- These machines form and fill bags with salt using an automatic system with a conveyor belt and sealers.

7. Carton sealing machines- These machines are used to seal salt boxes or cartons.

8. Manual filling machines- These machines are hand-operated and require manual input from an operator to fill salt into containers.

Salt packaging machines ensure that salt is packaged efficiently, accurately, and hygienically. They ensure a consistent quantity of salt is dispensed into each package and that the packaging meets the desired quality standards. The type of machine used, would depend on the specific packaging requirements of the salt product, and the desired production capacity and speed.

List The Process of “salt packaging machine”

The process of salt packaging involves several steps to ensure that the product is safe, clean, and properly packaged. Below is a brief description of the steps taken by a salt packaging machine:

1. Weighing: The salt is weighed accurately and put in a hopper. It is important to ensure that the right amount of salt is put into each bag.

2. Bag making: The packaging machine creates a bag from a roll of plastic film. The roll is unwound, and the bag is formed using a sealer. The bag size is determined by the amount of salt put into it.

3. Filling: The salt is filled into the bag using a chute or auger. The machine can either use gravity to fill the bag or an auger to push the salt into it.

4. Sealing: Once the bag is filled, it is then sealed using a heat sealer. This ensures that the salt stays inside the bag and prevents any spillage.

5. Printing: The packaging machine can print the necessary information such as the weight, expiry date, and product code onto the bag.

6. Inspection: The packaged bags undergo a quality inspection to ensure that they are properly sealed and meet the required standards.

7. Counting: The bags are then counted and packed into boxes or cartons for transport.

In conclusion, the salt packaging process involves several important steps to ensure that the product is properly weighed, packaged, and labeled. A salt packaging machine plays a significant role in automating this process, resulting in increased efficiency, reduced labor costs, and improved product quality.

How to use “salt packaging machine”

Salt packaging machine is a type of equipment that is designed to package salt in various forms, including powder, granules, and flakes. It is an automated system that ensures the smooth packaging of salt, without any manual intervention, and with minimal wastage. The salt packaging machine is equipped with several components, such as weighing scales, filling and sealing machines, and conveyor belts, which work together to ensure accurate and efficient packaging.

To use the salt packaging machine, the first step is to prepare the salt for packaging. This involves cleaning and drying the salt, and ensuring that it is free of any impurities. The salt should also be in the correct form, depending on the type of packaging machine being used. For example, if the machine is designed for granulated salt, the salt should be in granular form.

Once the salt is prepared, it is loaded onto the hopper of the salt packaging machine. The machine automatically weighs the salt and dispenses it into the packaging bag or container. The packaging material is then sealed, and the finished product is moved along the conveyor belt to the next stage of the process.

The salt packaging machine is designed to work at a high speed, allowing for fast and efficient packaging. It is also easy to operate, with simple settings and controls that can be adjusted as needed. The machine can be used for packaging various sizes and quantities of salt, depending on the needs of the manufacturer or supplier.

Overall, the salt packaging machine is an essential piece of equipment for any manufacturer or supplier of salt products. It ensures accurate and efficient packaging, saving time and reducing wastage, while also improving the quality and consistency of the finished product.

List Properties of “salt packaging machine”

Salt packaging machines are specially designed equipment that can automatically pack salt in various forms such as granules, pellets, or powder. Listed below are the properties of the salt packaging machine:

1. Material Construction – Salt packaging machines are made of durable and high-quality materials such as stainless steel. This supports the machine with its heavy-duty workload without compromising the quality of the packaged product.

2. Speed and Efficiency – Salt packaging machines are designed to operate at high speeds, making them very efficient in mass production applications. They can pack several thousand bags in an hour, making them an excellent investment for large-scale use.

3. Precision and Accuracy – A reliable salt packaging machine ensures accurate weight and the precise amount of product in each bag. It is designed with precision tools to minimize errors and guarantee high-quality packaging every time.

4. Flexibility in Packaging Size – Salt packaging machines can pack salt in various sizes ranging from small to large pouches according to the preference of the customer.

5. User-Friendly Interface – A salt packaging machine’s user interface is designed to be simple and intuitive with minimal training requirements. The ease of use to operate and maintain the equipment makes it efficient for the manufacturer and reduces downtime.

6. Multiple Safety Features – Salt packaging machines have multiple safety features that include sensors, interlocks, and alarms, ensuring safe operation and reducing the possibility of accidents.

7. Dust-Free Packaging – Salt packaging machines have dust collection features to ensure a dust-free production environment and improve the air quality of the production area.

Overall, the properties of the salt packaging machine are essential for large-scale salt manufacturing, packaging efficiency, and product safety.

List “salt packaging machine” FAQ

What is a salt packaging machine?

A salt packaging machine is a specially designed machine that packs salt into various sizes and quantities. It is a machine that makes the salt-packaging process efficient, cost-effective and automates the entire process.

What is the process of salt packaging?

The process of salt packaging starts with filling and sealing the bags or pouches of different sizes. The operator needs to feed the salt into the machine hopper, which then feeds the salt into the packaging system. The machine then automatically forms, fills and seals the bags.

What are the benefits of using a salt packaging machine?

The use of a salt packaging machine has several advantages such as reducing labor costs, increasing efficiency, and improving product quality. It also helps in minimizing the wastage of salt and ensures uniformity in packaging sizes.

What are the packaging sizes that a salt packaging machine can handle?

Salt packaging machines can handle a variety of packaging sizes such as small packets of 5g to large bags of 50kg or more. The packaging size can be adjusted according to the customer’s requirements.

What are the types of packaging materials that can be used in salt packaging machines?

Salt packaging machines can handle various types of packaging materials such as plastic bags, pouches, and sacks. The packaging material can also be customized according to the customer’s preference.

How much does a salt packaging machine cost?

The cost of a salt packaging machine depends on the type, size, and specifications. The cost ranges from a few thousand to several hundred thousand dollars.

What is the maintenance frequency for a salt packaging machine?

A salt packaging machine requires regular maintenance and cleaning to keep it in good condition. The maintenance frequency depends on the usage of the machine, but it is recommended to perform maintenance at least once a year.

Can a salt packaging machine be used for other products?

Yes, salt packaging machines can be used for packaging other products such as sugar, flour, rice, and other granular products.

In conclusion, salt packaging machines are efficient, cost-effective, and essential for industries that require the packaging of salt products. This machine assures the uniformity of packaging sizes while reducing labor costs, increasing efficiency, and improving product quality.