List Technical Parameters of "sauce packaging machine"

The sauce packaging machine is a highly specialized piece of equipment that is designed to package sauces and other viscous liquids into a variety of containers, including bottles, jars, and pouches. These machines are used extensively in the food processing industry, where they play a critical role in ensuring product quality, consistency, and safety. Here are some of the key technical parameters of a typical sauce packaging machine:

1. Capacity: The capacity of a sauce packaging machine is typically measured in units per hour, and can range from a few hundred units per hour for small machines to several thousand units per hour for larger machines.

2. Container type: The types of containers that a sauce packaging machine can handle can vary widely depending on the size and configuration of the machine. Some machines are designed to fill only bottles or jars, while others can handle pouches or other types of packaging.

3. Fill volume: The fill volume of a sauce packaging machine refers to the amount of sauce or other liquid that the machine can dispense into each container. This can range from a few milliliters to several liters, depending on the application.

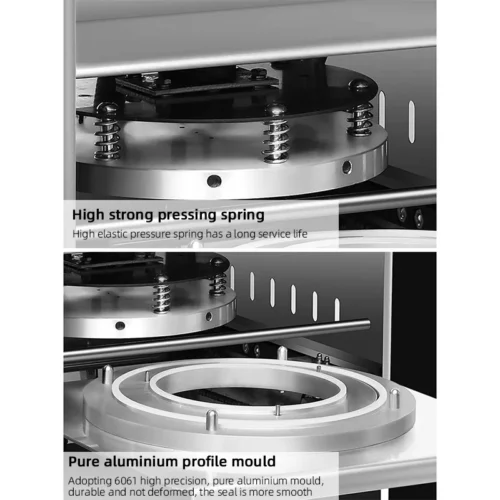

4. Accuracy: The accuracy of a sauce packaging machine is critical to ensuring that each container is filled to the correct level. Most machines have a built-in volume measurement system that ensures precise filling.

5. Speed control: The speed at which the sauce packaging machine fills containers can be adjusted to suit the specific needs of the application. This allows for greater flexibility and control over the filling process.

6. Cleaning and maintenance: A sauce packaging machine must be designed for easy cleaning and maintenance in order to ensure that it operates at peak efficiency and meets all regulatory requirements.

7. Material compatibility: The materials used in the construction of the sauce packaging machine must be compatible with the type of sauce or other liquid being packaged. This includes the type of container, as well as the materials used in the filling mechanism and the product contact surfaces.

8. Safety features: Sauce packaging machines may include a range of safety features such as interlocks, guards, and alarms to protect operators from hazards such as moving parts, high temperatures, and sharp edges.

Overall, the technical parameters of a sauce packaging machine are key to ensuring that the machine performs reliably and consistently over time, and can handle a wide range of sauce and liquid packaging applications. By carefully considering the specific needs of their application and selecting an appropriate machine, food processing companies can improve efficiency, reduce waste, and deliver high-quality products to their customers.

List Product features of "sauce packaging machine"

Sauce packaging machines are designed to package different types of sauces, including ketchup, mayonnaise, mustard, hot sauce, salad dressing, and barbecue sauce, among others. These machines come with various features that enable them to package sauces quickly, accurately, and efficiently. Below are some product features of a sauce packaging machine:

1. Automated filling process: The machine has an automated filling process that fills sauces into pouches or containers in a precise and consistent manner. This ensures that each pouch or container has the same amount of sauce.

2. Different filling sizes: The machine can fill different sizes of pouches or containers, depending on the needs of the customer.

3. Adjustable filling weight: The machine has an adjustable filling weight that allows for accuracy when filling different types of sauces.

4. Easy to operate: The machine is user-friendly, making it easy for operators to operate and maintain. This reduces downtime, which can affect production.

5. Easy to clean: The machine is designed to be easy to clean, reducing contamination risks and ensuring food safety.

6. High production rates: The machine can produce a large volume of sauce packs or containers in a short amount of time. This is useful for businesses that need to meet high demand.

7. Versatile design: The machine can be used to package various types of sauces, making it a versatile solution for businesses with multiple sauce products.

8. Compact design: The machine has a compact design, making it space-efficient, ideal for small to medium-sized businesses.

9. Custom packaging design: The machine can be customized to fit the needs of specific brands. This means that businesses can have their packaging design on their sauce pouches or containers.

10. High-quality packaging: The machine ensures the packaging of sauces is of high quality, which can help improve brand reputation and attract more customers.

Overall, sauce packaging machines come with various features that make them efficient, reliable, and cost-effective solutions for packaging different types of sauces. These features differentiate them from other packaging machines, making them a must-have for sauce packaging businesses.

List Application of "sauce packaging machine"

Sauce packaging machines are specialized types of packaging machines used in the food industry for the packing of various liquid or semi-liquid sauces. These packaging machines offer numerous benefits including enhanced product quality, efficient and streamlined production, and reduced costs. Below are a few applications of sauce packaging machines:

1. Side/portion control: Sauce packaging machines allow producers to offer single-serve portions of sauces in different packaging sizes. This ensures that enough sauce is included to enhance the dish taste while avoiding food wastage.

2. Convenience: These machines enable the packaging of grab-and-go options, increasing convenience for customers looking for a quick meal option.

3. Preservation: The packaging process ensures that the sauce is sealed using high-quality packaging material, thereby protecting the contents from contamination and ensuring long shelf life.

4. Brand recognition: The packaging also plays a significant role in establishing brand recognition by incorporating the company’s logo, product name, and other relevant information about the product.

5. Improved production efficiency: The introduction of automated sauce packaging machinery helps to streamline the production process, reducing human error, and saving time and money in the production process.

6. Reduced Waste: Sauce packaging machines can significantly reduce waste that comes from production. Ensure that the product is measured and filled to specific capacities, which translates to accurate amounts, less waste to discard.

7. Customer convenience: The use of these machines also makes it easier for customers to use sauces without making a mess. The packaging maintains the integrity of the sauce, making it stable and easy to dispense and use.

In conclusion, the sauce packaging machine plays an essential role in the food industry for an array of reasons. These machines offer unparalleled precision, time, and cost savings to businesses and enhance brand recognition and customer convenience for customers.

List Various Types of "sauce packaging machine"

Sauces are a vital component of any culinary experience, adding flavor, texture, and richness to meals. With this in mind, there are various sauce packaging machines available in the market. These machines cover various aspects of sauce processing and packaging, including filling, sealing, and labeling.

One of the most common types of sauce packaging machines is the automatic sauce filling machine. This machine is designed to fill a variety of sauces into containers of different shapes and sizes. It can handle low to high viscosity sauces and comes with an adjustable filling volume. The machine saves time and ensures consistent and accurate filling of sauce containers.

Another type of sauce packaging machine is the sachet filling and sealing machine. The machine creates sachets of sauce for single serve and sample purposes. The machine can produce sachets from a roll of film, fill them with sauce, and seal them. The sachet filling and sealing machine is suitable for small businesses that need cost-effective packaging solutions.

The tube filling and sealing machine is another popular type of sauce packaging machine. This machine specializes in filling and sealing tubes with sauces, making it ideal for mayonnaise, ketchup, and other condiments. The tube filling and sealing machine comes with a variety of features, including auto-capping, hot air sealing, and photoelectric tracking, among others.

The jar filling and capping machine is designed for filling and capping of sauces in jars. Jar filling and capping machine use a volumetric filling system, which enables it to dispense sauce with high accuracy and consistency. The capping system incorporates an automatic cap feeding and high torque capping system to ensure the jars are sealed tightly.

In conclusion, sauce packaging machines are essential in any food processing or manufacturing plant. They guarantee product quality, increase efficiency, and reduce labor costs. They come in different configurations, ranging from automatic filling systems to sachet filling and sealing machines. Depending on the specific needs of a business, the appropriate sauce packaging machine should be selected.

List The Process of "sauce packaging machine"

1. Material Preparation - First off, the packaging machine will require a set of materials such as the plastic film, sauce, and any other necessary additives such as preservatives. These materials should be made ready before the process commences.

2. Filling of Sauce - The packing machine is designed to fill the sauce into different containers, depending on the specifications of the customer. The size and shape of the container can be customized based on the choice and need of the consumer.

3. Sealing of Sauce - Once the sauce has been filled into the containers, the machine will automatically seal the package with heat. This prevents the sauce from leaking or allowing contaminants to enter, ensuring that the product is safe for consumption.

4. Labeling and Coding - After sealing, the package that contains the sauce gets labeled and coded with appropriate information such as the date of manufacture, the expiry date, batch number, and other essential details. These details are vital in keeping track of inventory.

5. Inspection and Quality Control - Before packaging, the container undergoes rigorous quality control and inspection to ensure that it meets the required standards. This process ensures that the sauce is entirely safe for customers to consume without causing any harm.

6. Palletizing - Once the packaging has been completed, the packages containing the sauce gets palletized and stacked onto the shelves awaiting distribution to various regions.

7. Delivery - Finally, the sauce gets delivered to retailers who sell them to the end consumers. The packaging machine aims to provide a complete end-to-end solution for the task of packing the sauce, ensuring that it is safe and convenient to use.

How to use "sauce packaging machine"

A sauce packaging machine is a type of automated packaging machinery designed to efficiently pack and seal liquid and semi-liquid sauces, dressings, and condiments. The machine automates the entire packaging process, from filling and sealing the containers to affixing labels and coding, providing a more streamlined and efficient method of product packaging.

To use a sauce packaging machine, the packaging material is first fed into the machine, which includes a roll of heat-sealable film or sachet that will be used to form the containers. The machine then automatically seals the bottom of each container, which can be in the form of a pouch, sachet, or stand-up bag depending on the need. The next step is for the sauce to be added in a predetermined amount. Some machines can be fitted with a sauce dosing system, which helps manage the amount of sauce dispensed per container.

After filling, the packaging material is sealed at the top of the container. Depending on the machine, it may also include a labeling and coding feature, which can be used to print information on the package, such as the expiration date, product code, and other relevant information.

Once the product is packaged, it is then ready for shipping and display. The machine is easy to operate and can be automated for faster production runs, reducing the need for manual labor in the filling and sealing of product containers.

Overall, a sauce packaging machine is an ideal solution for businesses looking to streamline their packaging operations and increase productivity in their production process. With easy-to-use controls, high efficiency, and low labor costs, it can significantly improve the bottom line of any business.

List Properties of "sauce packaging machine"

A sauce packaging machine is a specialized equipment that is designed for the packaging of different kinds of sauces. These machines are used in the food and packaging industry, where large quantities of sauces are produced, and their packaging must be done efficiently.

The properties of the sauce packaging machine include speed, accuracy, and versatility. These machines are precise and can package sauce in different kinds of packaging such as sachets, pouches, and bottles. They are also fast, with some machines capable of packaging up to 200 sachets per minute. This is particularly beneficial for industries that require large quantities of sauce products.

Another essential property of the sauce packaging machine is the material used in production. Most machines are made of stainless steel, which is durable, long-lasting, and easy to clean. The use of stainless steel helps to ensure that the machine is hygienic and safe for use.

The control mechanism is also a unique property of the sauce packaging machine. The machine is equipped with a computerized control system that monitors and regulates the entire process of sauce packaging. This system ensures that the machine is running efficiently and producing accurate results.

The sauce packaging machine also has a low operational cost. They are efficient in the use of power, and their maintenance cost is relatively low. This makes them a cost-effective solution for businesses that want to package their sauce products efficiently.

In conclusion, the properties of a sauce packaging machine make them an essential tool in the packaging industry. They offer speed, accuracy, versatility, durability, easy maintenance, and a cost-effective solution for businesses that produce sauces in large quantities.

List "sauce packaging machine" FAQ

Q: What is a sauce packaging machine?

A: A sauce packaging machine is a type of packaging equipment that is specifically designed to package and seal sauces, such as hot sauce, mayonnaise, ketchup, barbecue sauce, salsa, and other condiments.

Q: How does a sauce packaging machine work?

A: A sauce packaging machine generally works by filling, sealing, and labeling the sauce in individual portion sizes, such as sachets, pouches, or cups. The machine typically uses automated processes, including filling and sealing the packaging material, cutting the packaging to size, and labeling the finished product.

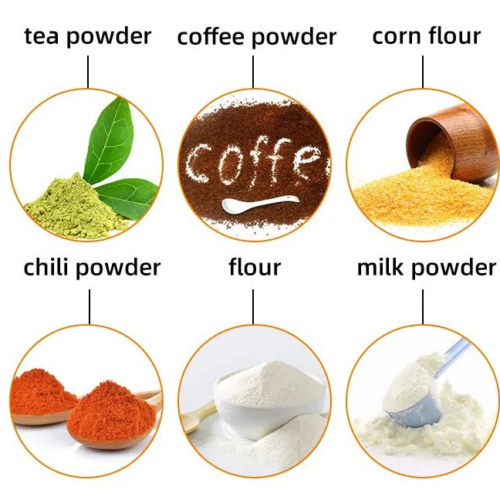

Q: What types of sauces can be packaged using a sauce packaging machine?

A: A sauce packaging machine can be used to package a wide variety of sauces, including liquid, semi-liquid, and thick sauces. Some common examples of sauces that can be packaged using a sauce packaging machine include salsa, hot sauce, tomato sauce, mayonnaise, mustard, ketchup, and other condiments.

Q: What are the benefits of using a sauce packaging machine?

A: The benefits of using a sauce packaging machine include increased efficiency, improved product quality, and reduced packaging waste. With automated processes, the machine can fill and seal the packaging quickly and accurately, resulting in consistent and uniform portions. This also reduces the risk of human error, such as overfilling or underfilling the packaging.

Q: What should I consider when choosing a sauce packaging machine?

A: When choosing a sauce packaging machine, you should consider the type of sauce you will be packaging, the packaging format you prefer, your production speed and volume requirements, and your budget. It is also important to ensure that the machine is compatible with your packaging materials and meets any safety and regulatory requirements.

Q: How much does a sauce packaging machine cost?

A: The cost of a sauce packaging machine can vary widely depending on the machine type, size, and capabilities. Generally, a basic model can cost several thousand dollars, while more advanced models can cost tens of thousands of dollars. It is important to consider the long-term benefits and cost savings of investing in a sauce packaging machine, as well as any financing or leasing options that may be available.