List Technical Parameters of “sausage packing machine”

The sausage packaging machine is an automated device specifically designed for packaging sausage products efficiently. It works by receiving sausages from the production line, aligning them, and then packaging them in various forms such as vacuum-sealed pouches, trays, and bags. The technical parameters of the sausage packaging machine include:

1. Material Handling: The sausage packaging machine should be able to handle different types of sausages, including fresh, cooked, smoked, and pre-cooked sausages.

2. Capacity: The capacity of the sausage packaging machine should be able to satisfy the production rate requirements of the meat processing facility. This will be directly related to the output of the line where it will be deployed.

3. Packaging Style: The sausage packaging machine should be able to support various packaging styles, including shrink-wrapping, vacuum-sealing, tray sealing, and bagging, among others.

4. Control System: The control system of the sausage packaging machine should be automated, user-friendly and reliable. It should feature touch screen interfaces that allow the user to select the corresponding packaging type to use.

5. Speed: The speed of the machine should be adjustable to accommodate different production rates.

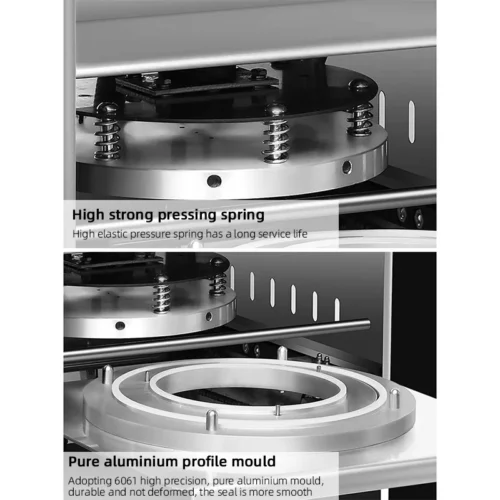

6. Reliability: The sausage packaging machine should be built to be robust and reliable, ensuring that it can operate continuously without breaking down or deteriorating.

7. Hygiene and Safety: The machine should be designed in such a way that it is easy to clean and maintain. All its components that come in contact with the product should be made of food-grade materials and allow for easy cleaning.

8. Power Supply: The machine should be designed to accommodate different electrical configurations, including single-phase and three-phase power supplies.

9. Maintenance: The sausage packaging machine should be easy to maintain, and all its components should be easily accessible.

10. Operational efficiency: The sausage packaging machine should be designed to minimize waste, rejections, and downtime, optimizing production at all times.

In summary, The sausage packaging machine is an essential component of any meat processing facility. Its technical parameters determine its efficiency, safety, and the quality of the packaged sausages. By selecting and maintaining the right parameters, a meat processing facility can optimize its sausage production line, minimize waste and maximize profitability.

List Product features of “sausage packing machine”

The sausage packing machine is a revolutionary piece of equipment that is designed to help food manufacturers and processors pack sausages in an efficient and effective manner. The machine is equipped with several features that make it easy to use and highly functional. Here are some of the key features of a typical sausage packing machine:

1. Automatic sausage loading: This feature enables the machine to load sausages onto the packing conveyor automatically, without the need for any manual intervention. This helps to save time and increase productivity, as the machine can work continuously without any interruptions.

2. Multiple packing options: The machine is designed to pack sausages in various sizes, from small to large, depending on the customer’s requirements. This flexibility makes it a versatile tool for food manufacturers, who can package different types of sausages as per their clients’ orders.

3. Adjustable speed and quantity: The machine’s speed and quantity settings can be easily adjusted to match the production rate required by the manufacturer. This helps to reduce wastage and optimize the production process, ensuring that the machine keeps up with the demand.

4. Easy to clean: The sausage packing machine is built with hygiene in mind. Its stainless-steel construction makes it easy to clean and maintain, ensuring that the machine is always in top condition for use.

5. Minimal downtime: The sausage packing machine is built to last, with durable and reliable components. This helps to minimize downtime and repair costs, ensuring that the machine is always available for use.

6. User-friendly interface: The machine’s user-friendly interface makes it easy to operate and control, even for first-time users. This saves time and reduces the risk of errors, ensuring that the machine operates effectively and efficiently.

7. Enhanced safety features: The machine is equipped with several safety features, such as emergency stop buttons and safety guards, to prevent accidents and protect operators from harm.

The sausage packing machine is a highly versatile tool that can help food manufacturers and processors improve their production output, reduce wastage, and enhance their quality control. With its advanced features, the machine offers a cost-effective and efficient solution for packing sausages, making it an essential investment for any food processing business.

List Application of “sausage packing machine”

The sausage packing machine is an automated and efficient equipment that is utilized in the packaging process of sausages. It packages the sausages reliably, quickly, and effectively in a variety of packaging types and sizes. Some of the applications of the sausage packing machine include:

1. Food Processing Industries: The sausage packing machine finds extensive applications in food processing industries. It is utilized to pack a range of sausages variants, including chicken, beef, pork, and lamb sausages.

2. Supermarkets and Butcheries: The sausage packing machine is also applied in supermarkets and butcheries. They are suitable for packing both fresh and smoked sausages. This application of the machine helps to maintain the quality and freshness of the product while extending the shelf life of the sausages.

3. Small Scale Industries: Small scale industries and manufacturers that produce sausages also benefit from the application of the sausage packing machine. This equipment is a cost-effective means to improve production and packaging efficiency, reduce labour costs, and increase profits.

4. Export and Distribution Companies: The sausage packing machine is used in companies that export sausages to different countries. It allows the sausages to be packed and transported safely in packaging that has a maximum resistance to rupture, tear, or breakage.

5. Meat Processing Plants: The sausage packing machine is widely used in meat processing plants. This application of the machine ensures that the sausages are hygienically and uniformly packaged in a reliable and repeatable manner.

In conclusion, the sausage packing machine plays a critical role in the food processing and packaging industry. The application of this equipment offers various advantages, including improved production efficiency, reduced labour costs, and increased profits. The machine is ideal for different users, including manufacturers, distributors, meat processing plants and so on.

List Various Types of “sausage packing machine”

Sausage packing machines are essential tools that help in the packaging of sausages. Various types of machines are available, and each model has its unique features depending on the user’s needs. Here are some common types of sausage packing machines:

1. Vacuum Sausage Packing Machines: This machine creates a vacuum environment through which sausages are passed for packaging. The vacuum environment helps to maintain the freshness of the sausages while protecting them against oxidation, dehydration, mold growth, and odor contamination.

2. Semi-Automatic Sausage Packaging Machines: This type of sausage packing machine requires some manual intervention. The machine forms, fills, and seals the sausage casing automatically, but the user will have to thread the casing and link the sausages manually.

3. Automatic Sausage Packaging Machines: The automatic sausage packing machine is designed to handle all the processes of sausage production. The machine forms, fills, and seals the sausage casing without human intervention.

4. Multifunctional Sausage Packing Machines: This machine is designed to pack different types of sausages with different shapes and sizes. It can adapt to various sausage casings and sausage types, which makes it versatile to use.

5. Continuous Sausage Packing Machines: This type of sausage packing machine comes with a high-speed conveyor belt that moves continuously, allowing for a constant supply of sausages. It is mostly used for industrial sausage packaging.

6. Mobile Sausage Packing Machines: This type of sausage packing machine is portable and can be moved around from one location to another. It is mostly used by small-scale sausage makers who do not have permanent production facilities.

In summary, sausage packing machines are essential tools that make the packaging of sausages easy and efficient. With the various types of machines listed above, users can choose the right model based on their production needs and budget.

List The Process of “sausage packing machine”

The process of a sausage packing machine involves several essential steps. Here are the key stages:

1. Preparation of the sausage: First of all, the sausages are made, which involves grinding, mixing and filling the meat. The sausage is made according to the recipe, and then the meat is put into the sausage casing.

2. Loading the sausage: The sausages are fed into the machine either individually or in groups. The loading process varies with different machines. For instance, some machines require the sausages to be loaded manually, while others can load automatically.

3. Sealing the sausage: Once the sausages are loaded into the machine, they are tightly sealed using a sealing mechanism. The sealing method can vary according to the machine type.

4. Cutting the sausage: After sealing, the sausage is cut into the desired length. The cutting process is usually triggered by a sensor, which then cuts the sausage.

5. Weighing the sausage: Sausages packing machines often weigh sausages during the process to ensure consistency. The machines use load cells to measure the exact weight of the sausage, which is then programmed into the machine.

6. Packaging the sausage: Once the sausage has been weighed, it is then packaged. The packaging can include heat-sealed bags, trays or vacuum-packed bags.

7. Labeling the sausage: The final step is to attach a label to the package, providing information such as the weight, shelf life, list of ingredients and nutrition facts.

In summary, a sausage packing machine process involves loading, sealing, cutting, weighing, packaging, and labeling. With a well-built machine, the process is incredibly fast and efficient. The process helps manufacturers to supply high-quality sausages, ensuring consistency, and meeting customer’s demand with ease.

How to use “sausage packing machine”

A sausage packing machine is a specialized piece of equipment that is used to pack sausages automatically. It is designed to help manufacturers produce large quantities of sausages in a short amount of time. The machine consists of several components including a hopper, a stuffer, and a casing dispenser.

To operate a sausage packing machine, the manufacturer first places the meat into the hopper, where it is mixed with ingredients such as spices and herbs. The mixture is then fed through a grinder and into the stuffer. The stuffer is used to fill the sausage casing, which is automatically dispensed from the casing dispenser.

As the sausage casing is filled with the meat mixture, it is twisted to form individual links. This process is repeated until all of the meat mixture has been used.

Once the sausages have been formed, they are usually placed on a conveyor belt, which transports them to a packaging station. At the packaging station, the sausages are typically packed into trays or vacuum-sealed bags.

The advantages of using a sausage packing machine are many. It can significantly increase production speed and efficiency, reduce labor costs, and improve product consistency. Additionally, the machine can help reduce the risk of contamination, as it is designed to work in a hygienic environment.

Overall, a sausage packing machine is a valuable investment for sausage manufacturers who want to improve their production processes. By streamlining the sausage packing process, it can help increase profits and enhance the quality of the products produced.

List Properties of “sausage packing machine”

A sausage packing machine is a specialized piece of equipment that is used to produce sausages in a bulk quantity efficiently. It is designed to increase productivity and ensure consistency in the processing phase. The following are the properties of sausage packing machines:

1. Durability: The machine is designed to last for many years and withstand constant use.

2. Automation: The machine is highly automated, reducing the need for manual intervention, and improving productivity.

3. Speed: The sausage packing machine can pack sausages at a faster rate compared to manual packing, making it a suitable choice for high volume production.

4. Versatility: The machine can be configured to accommodate different types of sausages, making it suitable for use in a wide range of sausage manufacturing processes.

5. Hygiene and sanitation: The machine is made of materials that are easy to clean, making hygiene and sanitation easier to maintain. This is essential to prevent the growth of harmful bacteria and to ensure food safety.

6. Precision: The sausage packing machine is designed to ensure that the correct amount of meat or filling is deposited into each casing, ensuring consistent sausage quality.

7. Safety: The machine is equipped with safety features that protect the operator from accidents, including emergency stop buttons and safety interlocks.

8. Energy efficiency: The machine is energy efficient, reducing the electricity consumption and operating costs.

9. Compact and space efficient: The machine has a compact design that occupies a small space. Hence, it is suitable for small and medium-sized businesses.

Overall, the properties of sausage packing machines help to achieve efficient, reliable, and consistent sausage production.

List “sausage packing machine” FAQ

Q: What is a sausage packing machine?

A: A sausage packing machine is a device used to package sausages for retail or commercial purposes. It automates the process of inserting sausages into casings, sealing them, and cutting them to the desired length.

Q: What types of sausage packing machines are available?

A: There are various types of sausage packing machines available including manual, semi-automatic, and fully automatic machines. Manual machines require a person to insert the sausage into the casing, while semi-automatic machines automate the process of casing the sausage but require manual intervention for cutting and sealing. Fully automatic machines can automatically insert, cut, tie, and package sausages without any human intervention.

Q: What are the benefits of a sausage packing machine?

A: A sausage packing machine offers various benefits such as increased production efficiency, improved product consistency and quality, and reduced labor costs. It also allows for faster turnaround times, increased safety, and reduced waste.

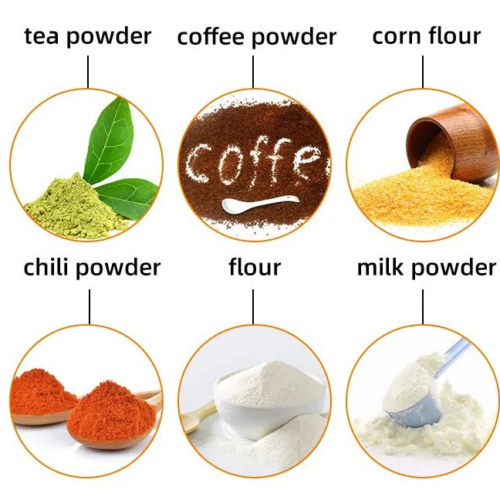

Q: What materials are used to make sausage packing machines?

A: Sausage packing machines are typically made of stainless steel or other food-grade materials that can withstand the rigorous demands of the sausage production process. These materials are easy to clean and maintain, and can prevent contamination and other health hazards.

Q: How do I choose the right sausage packing machine for my business?

A: When choosing a sausage packing machine, consider factors such as production volume, product size, casing type, and budget. It is important to research and compare different models and brands, and to consult with experts in the industry to ensure the machine meets your specific needs.

Q: How do I maintain a sausage packing machine?

A: Regular maintenance is necessary to keep a sausage packing machine in good working condition. This may include cleaning and sanitizing the machine after each use, and inspecting and replacing worn or damaged parts. It is also important to follow the manufacturer’s guidelines and schedule routine maintenance as needed.

Q: Can a sausage packing machine be customized?

A: Yes, some manufacturers offer customizations to meet specific requirements such as casing size, product shape, and packaging materials. However, customizations may come at an additional cost and may impact the overall production efficiency of the machine.

Q: What is the cost of a sausage packing machine?

A: The cost of a sausage packing machine varies depending on the type and model selected, as well as any customizations or additional features. Manual machines can cost anywhere from $500 to $2,000, while fully automatic machines can cost upwards of $50,000. It is important to consider the return on investment and long-term cost savings when deciding to invest in a sausage packing machine.