Introduction to Semi-Automatic Capsule Filling Machines

In the vast realm of pharmaceutical manufacturing, precision and efficiency are paramount. The Semi-Automatic Capsule Filling Machine stands as a testament to this, offering a seamless blend of automation and manual oversight. Designed to cater to both domestic and imported capsules, this machine is a game-changer for businesses aiming to upscale their production without compromising on quality.

The pharmaceutical industry, with its stringent standards and ever-evolving demands, requires equipment that is both robust and adaptable. The semi-automatic capsule filling machine fits this bill perfectly, ensuring that each capsule is filled with the exact dosage, every single time.

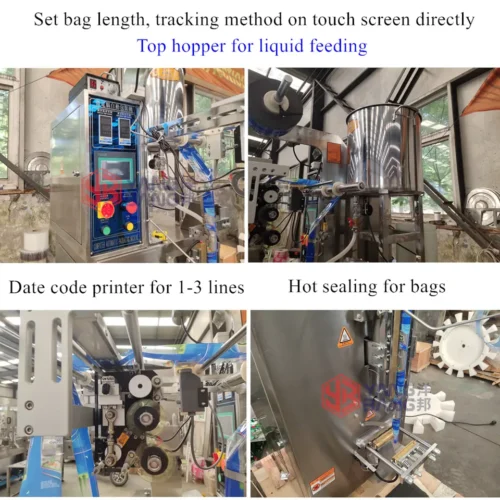

The machine's core functionality revolves around its ability to automatically locate, separate, fill, and lock capsules. This not only reduces labor intensity but also significantly boosts production efficiency, ensuring that the end product aligns with the rigorous sanitary requirements of the pharmaceutical domain.

The Uniqueness of PkgMach’s Capsule Filling Machine

In a market saturated with numerous capsule filling machines, PkgMach stands out for several reasons:

Custom Solutions: Every pharmaceutical company has unique needs. PkgMach understands this and offers tailored solutions to ensure optimal results. Whether you need a machine for a specific capsule size or a particular filling type, PkgMach has got you covered.

Wide Product Range: From honey packaging machines to automatic packers, PkgMach boasts a diverse product range, catering to various industries and requirements.

Reputation for Quality: PkgMach isn't just a manufacturer; it's a brand synonymous with quality. Their stringent quality control measures, combined with a dedicated expert team, ensure that every machine not only meets but exceeds industry standards.

Types and Applications of Capsule Filling Machines

Capsule filling machines aren't a one-size-fits-all solution. Depending on the application, different models might be more suitable:

Manual Capsule Filling Machines: Ideal for small-scale production or R&D purposes. They require manual input but offer precision.

Semi-Automatic Capsule Filling Machines: The perfect middle ground, these machines automate certain processes, boosting efficiency while still allowing manual oversight.

Fully Automatic Capsule Filling Machines: Best for large-scale production, these machines handle everything from sorting to filling, ensuring high-speed production without compromising on quality.

Different machines also cater to various industries, from pharmaceuticals and nutraceuticals to cosmetics and food supplements.

Step-by-Step Guide on Using the Semi-Automatic Capsule Filling Machine

1. Installation and Setup: Ensure the machine is placed on a level surface. Connect the power supply and the air pump.

2. Capsule Loading: Load the capsules into the machine, ensuring they are the correct size.

3. Filling Material Preparation: Prepare the material you wish to fill the capsules with, ensuring it's of the right consistency.

4. Machine Operation: Turn on the machine, adjust the settings as per your requirements, and let the machine handle the filling.

5. Regular Maintenance: Clean the machine components regularly to ensure smooth operation. Replace any worn-out parts as needed.

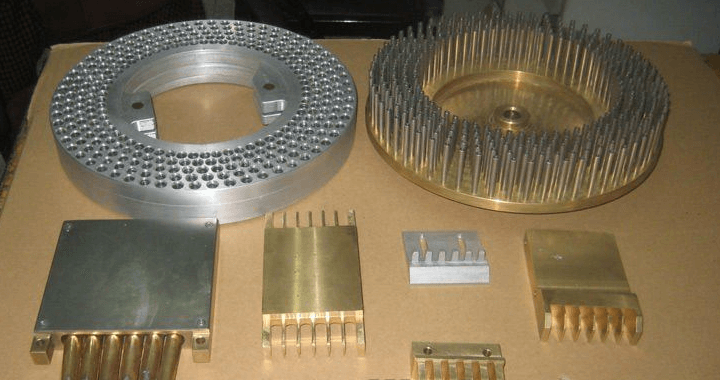

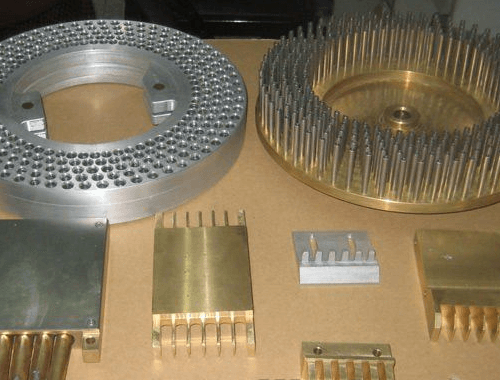

Insights into the Manufacturing Process

Design and Development: Every machine starts as an idea. Engineers and designers collaborate to create a machine that's both functional and efficient.

Quality Assurance: Once the machine is built, it undergoes rigorous testing to ensure it meets the set standards.

Packaging and Delivery: Once approved, the machine is carefully packaged and shipped to the customer, ready to boost their production capabilities.

Questions International Buyers Should Ask Chinese Suppliers

1. What certifications does your machine come with?

2. Can the machine be customized to suit specific requirements?

3. What post-purchase support do you offer?

4. How do you handle international shipping and customs?

5. Are there any additional costs involved, like installation or training?

FAQ Tips semi automatic capsule filling machine

- How often does the machine require maintenance?

Regular maintenance is recommended every 6 months, but it may vary based on usage. Always refer to the user manual for specific guidelines. - Is there a warranty for the machine?

Yes, the machine comes with a standard one-year warranty, covering any manufacturing defects. - Can the machine operate in high-humidity environments?

The machine is designed to operate in standard conditions. If you're in a high-humidity environment, it's advisable to use dehumidifiers to prevent any potential malfunctions. - What kind of customer support can I expect post-purchase?

We offer 24/7 customer support, including troubleshooting, spare parts replacement, and operational guidance. - Are there any training materials or tutorials available for new users?

Yes, every machine purchase comes with a comprehensive user manual, and we also offer online tutorials and training sessions if required. - How energy-efficient is the machine?

Our machine operates at a power of 2.12Kw, ensuring energy-efficient performance without compromising on productivity. - What safety features are integrated into the machine?

The machine comes with multiple safety features, including emergency stop buttons, overload protection, and safety interlocks to ensure operator safety. - How long is the delivery time after placing an order?

Typically, the delivery time is 3-4 weeks after the order confirmation, but it might vary based on customization requirements and shipping location. - Are there any specific storage conditions for the machine when not in use?

It's advisable to store the machine in a cool, dry place away from direct sunlight. Ensure it's covered to prevent dust accumulation. - Can the machine be integrated with other production line equipment?

Yes, our machine is designed to seamlessly integrate with other production line equipment, ensuring a smooth and efficient production process.