List Technical Parameters of “strip packing machine”

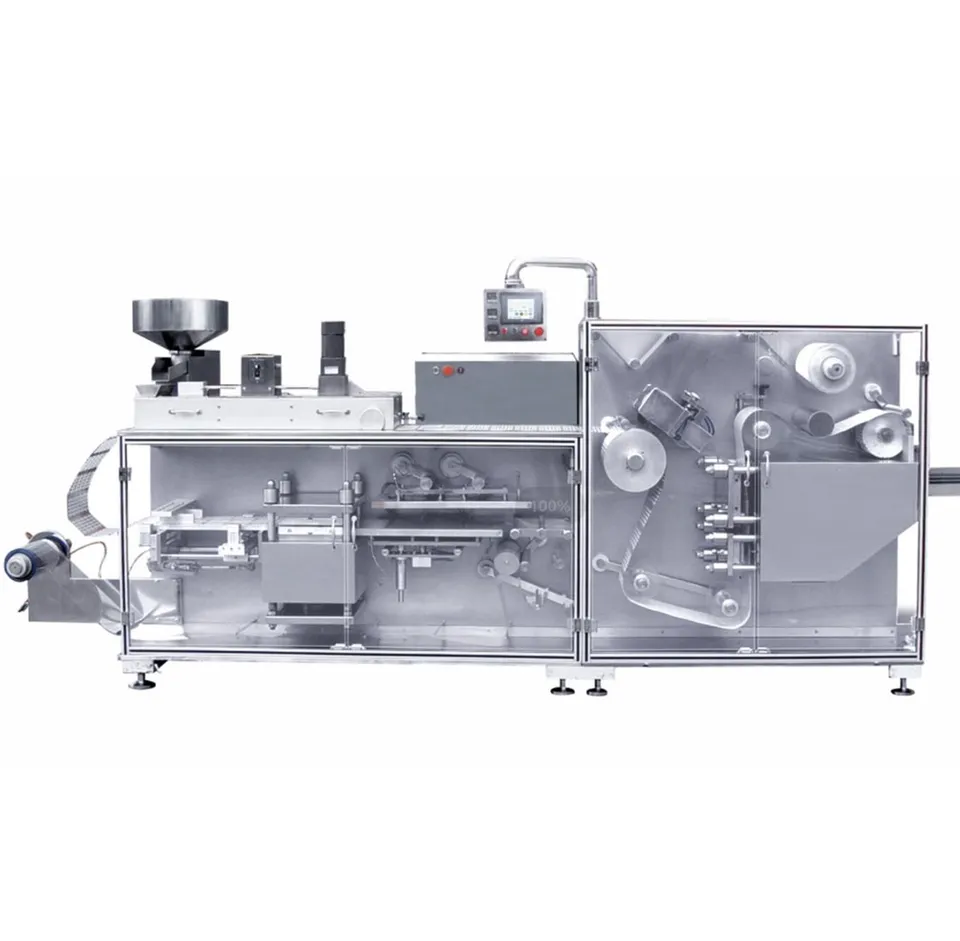

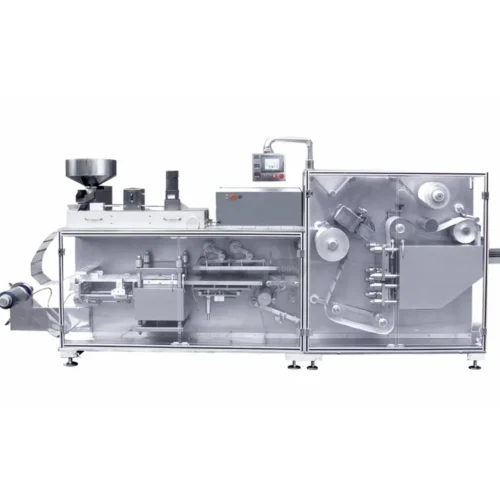

A strip packing machine is a type of packaging equipment that is used to package products in a continuous strip by sealing the edges of the packets. It is typically used in the food and pharmaceutical industries for packing tablets, capsules, candies, or other small products in individual packets.

Technical Parameters of a Strip Packing Machine

1. Size: The strip packing machine comes in different sizes, depending on the requirements of the user. They can range in size from small, table-top machines to larger, industrial-grade machines.

2. Capacity: The capacity of the strip packing machine is the number of packets that it can produce per minute. This can range from a few packets per minute to hundreds of packets per minute.

3. Material: The materials used in the construction of strip packing machines are typically stainless steel or other food-grade materials that are easy to clean and maintain.

4. Power Supply: The power supply for strip packing machines can vary depending on the size and capacity of the machine. Smaller machines may only require a standard electrical outlet, while larger machines may require a three-phase power supply.

5. Control System: The control system for strip packing machines can be either manual or automated. Manual machines require an operator to control the machine, while automated machines can be controlled by a computerized system.

6. Packaging Film Width: The packaging film width is the maximum width of the film that the machine can handle. This can range from a few millimeters to several centimeters, depending on the machine.

7. Sealing Method: Strip packing machines can use various sealing methods, including heat sealing, ultrasonic sealing, and cold sealing.

8. Strip Length: The strip length is the length of the packet produced by the machine. This can vary from a few millimeters to several centimeters, depending on the product being packaged.

Overall, a strip packing machine is an important piece of equipment for the food and pharmaceutical industries. By using the technical parameters listed above, manufacturers can choose the appropriate machine based on their production needs and requirements.

List Product features of “strip packing machine”

A strip packing machine is an automated packaging machine that is used to package tablets, capsules, and other similar products in strips. The machine is designed to operate efficiently, precisely, and with minimal human intervention. Here are some of the most important product features of a strip packing machine.

1. High-speed operation: A strip packing machine is capable of packaging products at very high speeds, up to 600 strips per minute. This makes it ideal for large-scale production environments.

2. Precision: The machine uses highly accurate sensors and controls to ensure that products are packaged with precision and consistency.

3. Versatility: Strip packing machines can be configured to work with a wide range of product sizes and shapes. This makes them a popular choice for small to mid-sized manufacturing facilities.

4. Ease of use: The user interface of modern strip packing machines is designed to be intuitive and user-friendly. This allows operators to easily control the machine and troubleshoot issues that may arise.

5. Efficient use of materials: Strip packing machines use materials very efficiently, minimizing waste and reducing costs.

6. Variety of packaging options: The machines can produce strip packaging in a variety of materials, including aluminum foil, PVC, and other laminates.

7. Compact design: Strip packing machines are typically designed to occupy a minimal amount of floor space, making them ideal for facilities with limited space.

8. Low maintenance: The machines require minimal maintenance, reducing downtime and maximizing productivity.

9. High reliability: Strip packing machines are built to last, with durable materials and components that ensure high reliability over years of operation.

10. FDA compliance: Modern strip packing machines are designed to comply with FDA guidelines for packaging pharmaceuticals and other sensitive products, ensuring both the safety and efficacy of the final product.

List Application of “strip packing machine”

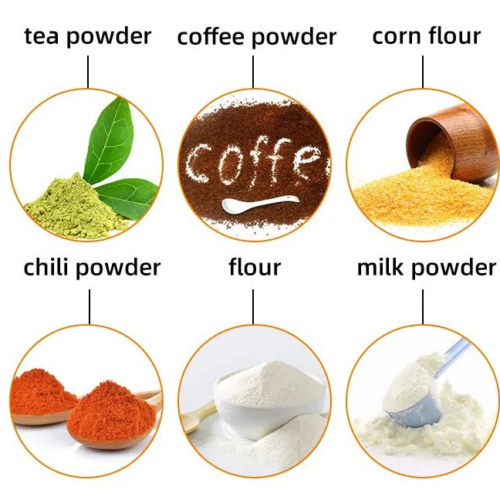

Strip packing machines are used to pack small, individual items in a narrow strip of plastic or paper. These machines are used in a variety of industries, including pharmaceuticals, food, cosmetics, and hardware. They are an essential tool in packaging automation systems due to their ability to pack items quickly and accurately. Here are some application of strip packing machines.

1. Pharmaceutical Industry: In the pharmaceutical industry, strip packing machines are used to pack tablets, capsules, and other small medical items. The machine creates an airtight seal, which helps to keep the medicine fresh and extends its shelf life. The machines’ high-speed operation allows pharmaceutical companies to produce large quantities of drugs in a short time, allowing them to meet their production targets.

2. Food Industry: The food industry also uses strip packing machines to pack small food items such as biscuits, candy, and chocolates. The machines use food-grade materials to ensure that the packed food products are safe to consume. Strip packing machines help food companies to meet their packaging needs, reduce wastage, and increase their overall productivity.

3. Cosmetics Industry: The cosmetics industry uses strip packing machines to pack small cosmetic items such as lipsticks, mascara, and eye shadow. The machines pack the products attractively, making them an excellent tool for enhancing brand image and improving sales. Strip packing machines also help cosmetic companies reduce packaging costs and improve their production efficiency.

4. Hardware Industry: The hardware industry also uses strip packing machines to pack small parts such as screws, nuts, and bolts. The machines’ accuracy and speed make them ideal for packing such small items accurately, ensuring that each package has the right number of parts. This makes it easy for hardware companies to track and manage their inventory.

In conclusion, strip packing machines have a wide range of applications in various industries such as pharmaceuticals, food, cosmetics, and hardware. They help companies increase their productivity, reduce packaging costs, and improve their production efficiency. Due to their versatility and reliability, strip packing machines are a vital component of packaging automation systems.

List Various Types of “strip packing machine”

Strip packing machines are widely used in the packaging industry to produce sealed, airtight strips of packaged products such as pharmaceuticals, confectioneries, and food. There are various types of strip packing machines, each with unique features and capabilities, as described below:

1. Rotary strip packing machine – This machine has a rotating drum with multiple pockets that fills and seals strips of packaging materials in a continuous process. It is versatile and can handle a wide range of products.

2. Blister strip packing machine – It is a high-speed machine that creates a cavity or blister in a sheet of packaging material, fill it with the product, and then seals it to form a strip.

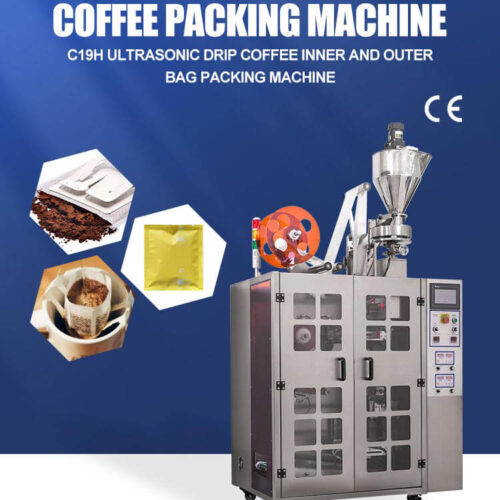

3. Sachet strip packing machine – This machine can produce small, single-dose sachets for packaging powders, granules, or liquids. It has the flexibility to produce different sizes of sachets and is ideal for low-output packaging lines.

4. Horizontal strip packing machine – This machine is designed for packaging products in a horizontal position. It is best suited for packaging irregular-shaped products and can handle a wide range of packaging materials.

5. Vertical strip packing machine – This type of machine is used for products that require vertical packaging, such as long and thin solid products. It is efficient and offers high output capacity.

6. Strip packing machine with perforation – It is a machine that can perforate the packaging material before sealing it to create easy-to-tear strips.

7. Strip packing machine with print registration – This machine can print the packaging material with product information or branding before forming and sealing strips.

In conclusion, strip packing machines offer a wide range of features and capabilities, making them an ideal choice for different packaging applications. Manufacturers can choose the type of machine that suits their needs based on product characteristics, output capacity, packaging materials, and other factors.

List The Process of “strip packing machine”

Strip packing machine is a type of automated packaging machine that is used to pack various products in strips or packets. The machine is designed with advanced features that make it easy to operate and ensure that the packaging process is carried out efficiently and effectively.

The process of strip packing machine begins with the preparation of the product intended for packaging. The product can be in solid, liquid, or semi-liquid form. This is done by ensuring that the product is at the appropriate temperature and consistency to ensure it can be adequately sealed during the packing process.

After preparing the product, the strip packing machine is set up to begin the packaging process. The machine’s feeding system, which consists of a set of rollers, is adjusted to ensure the correct width and thickness of the strip are fed through the machine. The machine also has a cutting system that can cut the strip into the desired length.

The product is then dispensed onto the strip either manually or automatically, depending on the machine’s configuration. Once the product is dispensed, the strip is then sealed, either by heat or pressure, to ensure that the product is adequately contained and protected.

The sealed strips are then cut into individual packets or pouches by the machine’s cutting system. The pouches are then discharged from the machine and are ready for further processing or distribution.

The strip packing machine is designed to work continuously without any interruption. The machine is made with high-quality materials, and it is reliable and durable, making it a perfect fit for any industrial or commercial packaging operation.

In conclusion, the strip packing machine is an essential tool for efficient and effective automated packaging. By following the process outlined above, the machine can help users pack various products quickly, efficiently, and cost-effectively.

How to use “strip packing machine”

Strip packing machine is a packaging equipment which is designed to wrap or seal a wide range of products such as tablets, capsules, candy, and other small items. This machine can handle a variety of packaging materials such as aluminum foil, cellophane, and polyethylene. It is commonly used in the pharmaceutical, food and beverage, and cosmetic industries.

To use a strip packing machine, start by adjusting the machine settings to ensure that it is capable of handling the materials and size of your product. Next, load the required packaging material into the machine. After that, feed your products into the machine where they will be wrapped or sealed.

During the packaging process, ensure that the products are properly aligned to ensure that they are correctly sealed. Additionally, check the sealing temperature and speed to make sure that they are appropriate for the material being used. Once the packaging is complete, remove the packaged products and store them safely.

The strip packing machine has several advantages. It is highly efficient, and the packaging process is relatively fast. Additionally, it seals products effectively, ensuring that they are not contaminated during the packaging process. This machine is also versatile and can handle a variety of products and materials.

In conclusion, using a strip packing machine is a simple process that requires adjusting machine settings, loading materials, and feeding products into the machine. Proper alignment and checking the sealing temperature and speed are crucial in ensuring that products are sealed correctly. This machine is efficient, versatile, and effective, making it an ideal packaging solution for various industries.

List Properties of “strip packing machine”

Strip packing machines are designed to pack strips or collations of different products including tablets, capsules, lozenges, and chewing gums. These machines are commonly used in the pharmaceutical and cosmetic industries due to their high precision and accuracy. Here are some properties of strip packing machines:

1. High speed and efficiency: Strip packing machines are designed to pack thousands of tablets or capsules in one hour, making them very efficient.

2. Customizable packing options: These machines can pack different product sizes and shapes, and they are designed to provide flexible packing options to meet different customer needs.

3. Accurate and precise packing: Strip packing machines come with advanced sensors and automatic feeders that ensure accurate and precise packing of the collations.

4. Easy to operate and maintain: These machines are easy to operate and come with a user-friendly interface that requires minimal training. Maintenance is also easy since most parts are easily replaceable.

5. Durable and robust: Strip packing machines are made of high-quality materials that make them long-lasting and robust, reducing downtime and increasing productivity.

6. Cost-effective: Purchasing a strip packing machine is a cost-effective investment that saves on labor costs and increases production efficiency.

7. Compliance with industry standards: Strip packing machines are designed to comply with regulatory standards, including Good Manufacturing Practices (GMP), ensuring the safety and quality of the packed products.

In conclusion, strip packing machines offer high-speed packing, customization, accuracy, durability, and compliance with industry standards, making them an ideal solution for collating and packing different types of products in the pharmaceutical and cosmetic industries.

List “strip packing machine” FAQ

1. What is a strip packing machine?

A strip packing machine is a type of packaging machine that packages products by sealing them in a strip of flexible packaging material, such as plastic or aluminum foil.

2. What is the application of a strip packing machine?

Strip packing machines are commonly used in the pharmaceutical industry to package tablets, capsules, powders, and other small items. They are also used in the food and cosmetic industry to package products such as chewing gum, mints, and facial wipes.

3. How does a strip packing machine work?

The strip packing machine works by feeding the products into individual pockets, which are then sealed with the flexible packaging material. The sealed strips are then cut into individual pouches through a cutting mechanism.

4. What are the benefits of using a strip packing machine?

The benefits of using a strip packing machine include the ability to package small items quickly and efficiently, the ability to pack a large volume of products at once, and the ability to ensure product integrity and shelf life.

5. What materials can be used with a strip packing machine?

Strip packing machines can use a variety of flexible packaging materials, including plastic and aluminum foil. The selection of the packaging material depends on the product being packaged and its required shelf life.

6. Can strip packing machines handle different sizes and shapes of products?

Strip packing machines are designed to handle a wide range of product sizes and shapes. The machine is typically adjustable to accommodate the size and shape of the product being packaged.

7. What are the maintenance requirements for a strip packing machine?

The maintenance requirements for a strip packing machine include regular cleaning, lubrication of moving parts, and replacement of worn parts as needed. The machine should be serviced by a qualified technician on a regular basis to ensure optimal performance.

8. What is the cost of a strip packaging machine?

The cost of a strip packaging machine varies depending on the size and complexity of the machine, as well as the application. Typically, prices range from several thousand dollars to tens of thousands of dollars.

9. How long does it take to set up and start operating a strip packing machine?

The set-up and operation time for a strip packing machine varies depending on the size and complexity of the machine, as well as the operator’s experience. However, most machines can be set up and running within a few hours with proper instruction and training.

10. Where can I purchase a strip packing machine?

Strip packing machines can be purchased from a variety of manufacturers and distributors. It is important to research and compare options before making a purchase to ensure the best fit for your specific needs and budget.