List Technical Parameters of "thali packing machine"

The technical parameters of thali packing machine include various aspects such as the size and capacity of the machine, the material used to manufacture the machine, the power requirements of the machine, and the speed at which it operates. Additionally, the machine may offer different functions or features that can impact its performance, such as automatic feeding, sealing, and cutting.

One of the primary parameters of thali packing machine is its capacity, which is determined by the size of the machine and the number of thalis it can handle at once. The capacity may vary from one model to another, with some machines capable of packing up to 500 thalis per hour. The size of the thalis that can be packed may also be a factor, with some machines designed to pack different sizes of thalis.

Another important parameter is the material used to manufacture the machine. The machine must be durable and resistant to wear and tear, and it should also be easy to clean and maintain. Common materials used for thali packing machines include stainless steel, aluminum, and sealable plastic.

Power requirements for thali packing machines are also an important parameter. The machine may require single-phase or three-phase power, with voltage ratings that can vary from 220 to 440 volts. Additionally, the machine may require a specific amount of power consumption per hour, usually ranging from 2 to 3 kilowatts per hour.

Finally, the speed of the machine is also a crucial parameter. The machine may be capable of packing thalis at different speeds, ranging from 20 to 50 thalis per minute. Some machines may also offer adjustable speed settings, allowing operators to control the speed based on their specific requirements.

Overall, thali packing machines are designed to make the process of packing thalis more efficient and streamlined. By considering the various technical parameters of these machines, businesses can select the right machine for their needs, ensuring that they can pack thalis quickly and effectively.

List Product features of "thali packing machine"

Thali packing machine is an efficient and reliable packing solution that is designed to pack food thalis in a hygienic and convenient manner. This machine is ideal for restaurants, hotels, food courts, canteens, and other food businesses that want to streamline their packaging process and improve their efficiency. Here are some of the key features of the thali packing machine:

1. High-speed packing: Thali packing machine is designed to pack thalis at a high speed, which can save a significant amount of time and effort for food businesses. It can pack up to 200 thalis per hour, depending on the size of the thali.

2. Customizable packaging: This machine can be customized to pack different sizes and types of thalis, depending on the requirements of the business.

3. Hygienic packaging: Thali packing machine ensures that the thalis are packed in a hygienic and contamination-free environment, which is essential for food businesses to maintain the quality and safety of their food products.

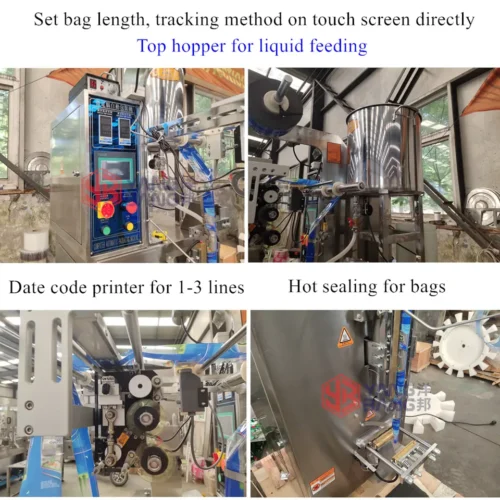

4. User-friendly operation: The machine is easy to operate and requires minimal training. It has a user-friendly interface that allows operators to set the packing parameters and monitor the packing process.

5. Durable construction: Thali packing machine is built to last, with a robust and durable design that can withstand the rigors of daily use in a food business.

6. Low maintenance: The machine requires minimal maintenance, with easy-to-clean components that can be quickly disassembled for cleaning.

7. Energy-efficient: Thali packing machine is designed to be energy-efficient, which can help food businesses save on their energy costs and reduce their carbon footprint.

8. Cost-effective: Thali packing machine is an affordable and cost-effective solution that can help food businesses improve their productivity and profitability.

In conclusion, thali packing machine is an essential tool for any food business that wants to improve its packaging process and meet the demands of its customers. With its high-speed packing, customizable packaging, hygienic packaging, user-friendly operation, durable construction, low maintenance, energy efficiency, and cost-effectiveness, thali packing machine is an investment that can pay off quickly and deliver long-term benefits for the business.

List Application of "thali packing machine"

Thali packing machines are highly automated pieces of equipment that are used to pack food thalis in various industries. Thalis are plates that hold a variety of Indian foods, including rice, dal, vegetables, and roti. Below are some of the applications of the thali packing machine:

1. Food Manufacturing Industry

Thali packing machines are extensively used in the food manufacturing industry for packaging purposes. They are utilized to pack the thalis and make them ready for distribution to various retail stores and supermarkets.

2. Canteens and Messes

Thali packing machines are used in canteens and messes to pack thalis quickly and efficiently. This helps in decreasing the time required for packing and makes the process streamlined.

3. Banquet Halls and Catering Services

Thali packing machines are used in banquet halls and catering services to pack food thalis for events like weddings, receptions, and corporate events. Thalis can be packed in bulk using these machines, helping in reducing the time and effort of employees.

4. Hospitals

Thali packing machines are used in hospitals as they can pack food thalis quickly and efficiently. This helps hospital staff save time and energy when serving meals to patients.

5. Airlines

Thali packing machines are utilized by airlines to pack food thalis for in-flight meals. The machines are designed to quickly pack thalis, and they can also be customized to pack food items as per the airline's specific requirements.

6. Self-help Restaurants

Thali packing machines are used in self-help restaurants that offer unlimited meals. The machines help in packing thalis in a quick and orderly manner and help in reducing the waiting time of customers.

Overall, thali packing machines are an essential piece of equipment in various industries. Their ability to automate the process of packing thalis and their efficiency make them an indispensable tool in many businesses.

List Various Types of "thali packing machine"

A thali packing machine is a type of packaging machine used to pack Indian thalis. Thalis often consist of multiple food items, such as rice, vegetable curries, dal, roti, and yogurt, served together on one plate. There are different types of thali packing machines available in the market based on several factors.

1. Semi-Automatic Thali Packing Machine- This machine is commonly used for packing single thalis in plastic sheets. The machine sealing and cutting of the sheets are semi-automatic and require minimal human effort.

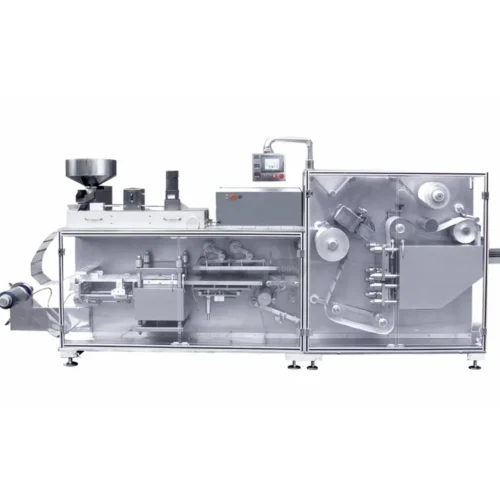

2. Fully Automatic Thali Packing Machine- This machine is highly automated and is designed to pack multiple thalis per minute. The machine is equipped with an automatic feeder that adds thalis to the conveyor, and once on the conveyor, the machine forms the thalis with plastic sheets and seals the packs.

3. Mini Thali Packing Machine- This type of thali packing machine is meant for small businesses, food stalls, and home-based businesses. The machine is small and straightforward with a low production capacity.

4. Double-Thali Packing Machine- This machine can pack two thalis at the same time with high speed and accuracy. It’s suitable for high production capacity restaurants and hotels.

5. Hydraulic Thali Packing Machine- This machine utilizes hydraulic energy to pack the thalis. It’s not automated, and the production rate is low compared to the automated machines.

6. Manual Thali Packing Machine- This machine requires manual effort to seal the thali packs.

7. Pneumatic Thali Packing Machine- This machine uses compressed air to pack the thalis. The machine is semi-automatic and can pack up to eight thalis per minute.

8. Electric Thali Packing Machine- This is a high-speed machine that uses electricity to pack the thalis. It’s fully automated and can pack up to 600 thalis per hour.

In conclusion, there are various types of thali packing machines available in the market. Each machine has its strengths and weaknesses. The selection of the right machine depends on the production requirement, the type of restaurant, and the budget.

List The Process of "thali packing machine"

The process of thali packing machine involves several steps that enable it to perform the critical task of packaging thalis in a quick and efficient manner. The following are the key steps in the process of thali packing machine:

1. Preparing the thalis: Before the packaging process can begin, the thalis need to be prepared. This involves stacking them up and placing them in a way that makes them easy to load into the machine.

2. Loading the thalis: Once the thalis have been stacked up, they are loaded onto the conveyor belt of the machine. The thalis should be placed in a way that allows them to move through the packaging process smoothly.

3. Wrapping the thalis: Once the thalis have been loaded onto the conveyor belt, the packaging process begins. The thalis move through the machine, and plastic sheets are used to wrap them up.

4. Sealing the thalis: Once the thalis have been wrapped up, they are sealed. This is done using a heat sealing process, which ensures that the packaged thalis are airtight and can be transported without any issues.

5. Cutting and separating the thalis: After the thalis have been sealed, they are cut and separated. This is done using a cutting mechanism that ensures each thali is separated from the others.

6. Ejection of packaged thalis: Finally, the packaged thalis are ejected from the machine. The packaged thalis are now ready to be transported and can be stored without any problems.

In conclusion, the thali packaging machine is a very efficient and useful device that can package thalis in a quick and efficient manner. With the above steps, you can easily understand how the process works and why it's important for the food packaging and the transportation sectors.

How to use "thali packing machine"

Using a thali packing machine is a simple and efficient way to pack thalis, which are traditional Indian dishes that typically consist of a variety of curries, rice, and breads. These machines are designed to simplify the thali packing process by automating the filling and sealing of the containers.

To use a thali packing machine, the first step is to ensure that the machine is clean and properly calibrated. The next step is to fill the thali containers with the desired components, including rice, curry, and any other accompaniments. Once the containers are filled, they are passed through the machine, which applies a seal to the top of the container to prevent spills and maintain freshness.

There are several benefits to using a thali packing machine. Firstly, it can greatly increase the speed and efficiency of thali production, making it possible to produce a large number of thalis quickly and consistently. Additionally, using a thali packing machine can help to reduce food waste and preserve the freshness of the food, which can help to improve the quality of the end product.

Overall, using a thali packing machine is a simple and effective way to pack thalis. Whether you are a restaurant owner or a caterer looking to streamline your operations, investing in a thali packing machine can be a valuable investment in your business.

List Properties of "thali packing machine"

Thali packing machines are a type of packaging machinery designed to cater to the food industry specifically. These machines are utilized for packaging food items such as thalis, plates, and other similar items. They are incredibly efficient, and their use has become an essential aspect of the food packaging industry.

Here are some of the properties of thali packing machines:

1. Automated: The thali packing machine is a fully automated machine that ensures quick and efficient packing. The machines are designed to be automated, which means that they require minimal human intervention to operate.

2. High Speed: The machines are designed to have high-speed operations and can pack several thalis in a minute. This enables the food industry to pack food items quickly, without any delays.

3. Accuracy: Thali packing machines come with a high level of accuracy, ensuring that the thalis are packed precisely. The level of accuracy leads to reduced wastage of packaging materials, which saves time and resources.

4. Versatility: The machines are versatile and can be customized to pack different types of food items, including round and rectangular thalis, plates, and more.

5. Durable: Thali packing machines are built to last, made of strong materials and able to withstand continuous use. This ensures they provide users with a long-lasting and cost-effective solution.

6. User-friendly: The machine requires minimal training to operate due to the user-friendly design. This lessens the burden of operating the machine and ensures that it is compatible with different users.

Overall, thali packing machines are an essential investment for the food packaging industry. They are efficient, cost-effective, durable, and user-friendly while ensuring a high level of accuracy and speed. It improves the food industry's productivity and user interface, leading to more profits and satisfied customers.

List "thali packing machine" FAQ

Q1. What is a thali packing machine?

A thali packing machine is a type of packaging equipment that is designed to pack food items into a thali. It has the capability to pack a variety of food items such as rice, curry, vegetables, and more.

Q2. How does a thali packing machine work?

The thali packing machine works on a mechanical process that involves placing the thali on the designated platform, and then the machine will automatically fill each compartment with the desired food items. Once the thali has been filled, the machine will wrap it in a plastic film or container to provide secure and hygienic packaging.

Q3. What are the benefits of using a thali packing machine?

The thali packing machine can provide several benefits to businesses and food production companies, including increased productivity, improved hygiene, and increased efficiency. The machine can handle a large volume of thali packing, which can save time and effort, while ensuring that the food supplied is consistent and of high quality.

Q4. How is the thali packing machine different from other packaging machines?

The thali packing machine is designed specifically for packing food items into a thali. Unlike other packaging machines, it has compartments and regions that are uniquely sized and shaped to accommodate the dimensions of a thali. This machine also has special features like automatic thali detection, customizable packaging options, and more, which helps differentiate it from other packaging machines.

Q5. How can I choose the right thali packing machine for my business?

To choose the right thali packing machine for your business, you need to assess your business needs and the volume of thali packing you require. You should also consider the space available in your premises, the budget you have for investing in a machine, and any specific features you require. Look for a reliable and reputed manufacturer who has a track record of producing quality machines.

Q6. How much does a thali packing machine cost?

The cost of a thali packing machine can vary depending on factors such as the manufacturer, type, model, and features of the machine. Generally, it can cost anywhere between 50,000 INR to 5 lakhs INR or more. It is important to keep in mind that the cost of the machine should be weighed against the benefits it can provide to your business.