List Technical Parameters of "used stretch wrap machine"

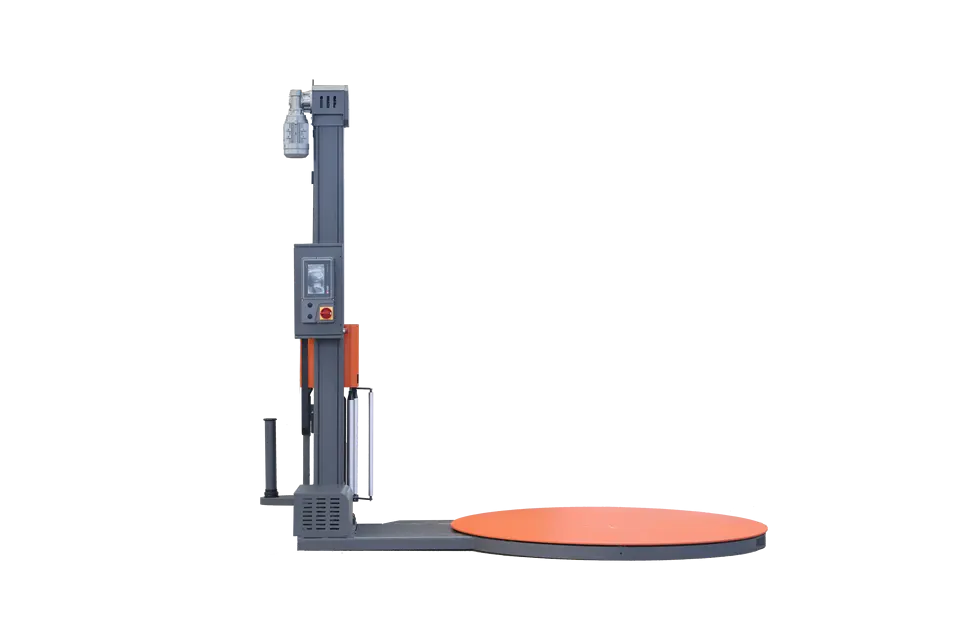

A stretch wrap machine is a packaging machine that is used to wrap pallets or products using a stretch film. A used stretch wrap machine is a machine that has already been used and possibly refurbished to work like new.

Technical parameters of a stretch wrap machine include the machine's height, width, and weight. These factors determine the machine's mobility and the space it can occupy in a warehouse or manufacturing plant.

The machine's maximum load weight should also be considered, as this determines the amount of weight the machine can handle during operation. The machine's speed is another important technical parameter, as this determines how many pallets or products can be wrapped in a given time.

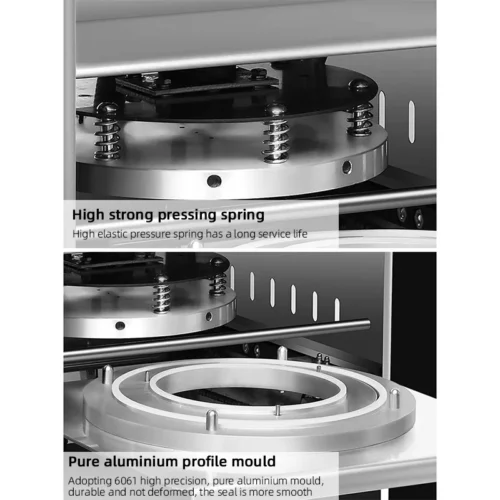

The machine's film specifications are also important. These include the type of stretch film that can be used, the maximum width of the film, and the thickness or gauge of the film. These factors determine the quality of the wrapping and the amount of film used per wrap.

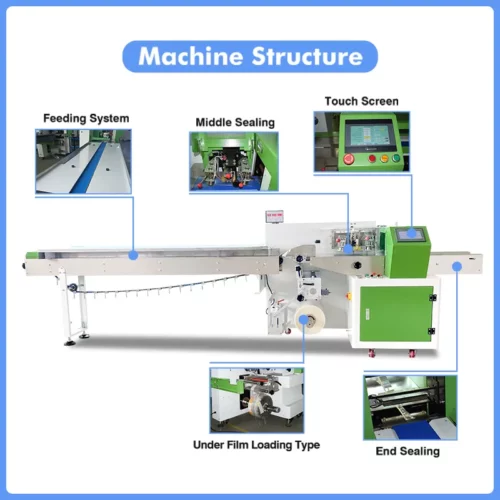

The stretch wrap machine's automatic features, such as automatic film cutting and wrapping cycle, determine the level of automation and the ease of operation. The machine's power supply also determines how much power is required to operate the machine, and whether a three-phase or a single-phase power supply is needed.

Other technical parameters to consider include the machine's control system, which determines how the machine is programmed, and the type of conveyor system the machine uses. The machine's safety features, such as emergency stop buttons and safety guards, are also critical in ensuring the safety of the machine operator.

In summary, technical parameters of a used stretch wrap machine include its height, width, weight, maximum load weight, speed, film specifications, automatic features, power supply, control system, conveyor system, and safety features. These parameters determine the machine's efficiency, effectiveness, and safety during operation.

List Product features of "used stretch wrap machine"

Used stretch wrap machines are a cost-effective solution for businesses that want to automate their pallet wrapping operations. These machines come in different types like semi-automatic, automatic, and robotic with various features that make them appealing to different types of businesses.

1. Pallet capacity - Used stretch wrap machines have different pallet capacity. Depending on the business requirements, users can choose from a range of machines that can handle 30-40 pallets per hour up to 100+ pallets per hour.

2. Film carriage - A film carriage is a crucial component of a stretch wrap machine and comes in two types - powered and manual. Powered film carriages offer high throughput and reliability, while manual film carriages are ideal for low-volume operations.

3. Turntable speed - Turntable speed determines how quickly the machine can wrap the pallet. A faster turntable speed is essential for high-volume operations as it can reduce the time required to wrap pallets.

4. Film tension - Used stretch wrap machines offer adjustable film tension, which is essential for securing the load on pallets. The adjustable film tension ensures that the load is protected during transportation.

5. Film pre-stretch - Film pre-stretch is a feature that stretches the film before wrapping it on the pallet. This feature ensures that lesser film is required to wrap the pallet and results in cost savings over time.

6. Control panel - Used stretch wrap machines come with a control panel that allows users to choose between different machine settings. The control panel allows users to adjust the turntable speed, film tension, and other settings according to their requirements.

7. Safety features - Used stretch wrap machines come with safety features such as emergency cut-off switches, fencing, and light curtains. These features ensure that the operator is safe while using the machine.

8. Maintenance - Used stretch wrap machines require periodic maintenance to ensure that they are operating efficiently. Make sure to choose a machine that is easy to maintain and has readily available parts when required.

Overall, used stretch wrap machines come with various features that make them a versatile and cost-effective solution for pallet wrapping operations. Careful consideration of the above features will help businesses choose the right machine that meets their needs.

List Application of "used stretch wrap machine"

A used stretch wrap machine, also known as a used pallet wrapping machine, has a wide range of applications in various industries. Some of these applications are:

1. Warehouse and Logistics: This is one of the most common applications of a used stretch wrap machine. In warehouses and logistics facilities, pallets are wrapped with stretch wrap to protect goods from damage during transport or storage. Wrapping with a used stretch wrap machine ensures that goods are tightly secured and remain in place during movement.

2. Manufacturing: In manufacturing facilities, products are often stored on pallets. Wrapping these pallets with a used stretch wrap machine keeps them from shifting or falling during transportation. Using a stretch wrap machine can also save time and labor costs compared to wrapping by hand.

3. Retail: Retail stores use stretch wrap machines to secure products on pallets to be transported to different locations or for storage. Used stretch wrap machines are popular among retailers due to their reliability and ability to wrap pallets quickly and efficiently.

4. Food and Beverage: Used stretch wrap machines are also used in the food and beverage industry to wrap pallets of products such as canned goods, bottled beverages, and perishable items. Stretch wrapping helps prevent contamination, spoilage, and damage during transportation or storage.

5. Pharmaceuticals: In pharmaceuticals, stretch wrapping helps prevent contamination and maintain the integrity of products during transportation or storage. Used stretch wrap machines can help ensure that pharmaceutical products are securely wrapped and protected.

In conclusion, a used stretch wrap machine has numerous applications across various industries. From protecting goods during transportation to maintaining product integrity, it is an essential tool in ensuring safe and efficient movement and storage of goods.

List Various Types of "used stretch wrap machine"

Used stretch wrap machines are an essential manufacturing and packaging tool for businesses in various industries. These machines are designed to wrap products, pallets, and items of all sizes and shapes using stretchable films. The machines are available in different types, and each type has unique features, capabilities, and benefits.

1. Semi-Automatic Stretch Wrap Machines

Semi-automatic stretch wrap machines require human intervention to place the products on the pallet before starting the wrapping process. These machines are more economical than automatic machines and ideal for businesses wrapping small to medium-sized products.

2. Automatic Stretch Wrap Machines

Automatic stretch wrap machines automate the entire wrapping process without any human intervention. These machines are more efficient, can wrap higher volumes of products, and are suitable for businesses with high-volume of orders.

3. Rotary Arm Stretch Wrap Machines

Rotary arm stretch wrap machines consist of a rotating arm that wraps the film around the product pallet. These machines are suitable for wrapping very light or unstable loads. They are also ideal for use in dusty environments since they don't drag the pallet across the floor.

4. Turntable Stretch Wrap Machines

Turntable stretch wrap machines are the most common type, and they work by wrapping the film around the pallet while it rotates on a turntable. These machines are suitable for wrapping more stable loads, and they are available in both semi-automatic and automatic models.

5. Robot Stretch Wrap Machines

Robot stretch wrap machines are the latest type of stretch wrap machines. They use robotic arms to wrap the film around the products, and they are incredibly versatile and flexible. Robot stretch wrap machines are ideal for businesses that wrap products that are irregularly shaped or sized.

In conclusion, a business's choice of a used stretch wrap machine should be based on its specific packaging and product needs. By understanding the various types of used stretch wrap machines, businesses can identify the right machine that suits their specific requirements and budget.

List The Process of "used stretch wrap machine"

The process of a used stretch wrap machine involves several steps, starting with the selection of the appropriate machine for the specific packaging needs of a user. Once the machine has been acquired, it needs to be transported to its operational location and installed, usually with the help of a technician.

After installation, the machine needs to be configured with specific settings, depending on the type of product being wrapped and the desired level of tension required for proper wrapping. This can include selecting the appropriate film thickness, tension settings, and speed of rotation.

Once the machine is configured, it can be loaded with the product to be wrapped, which is usually placed on a turntable or conveyor belt. The stretch wrap film is then fed into the machine, where it is oriented across the product to hold it securely in place. As the turntable rotates, the stretch film is wrapped securely around the product to form a tight, protective seal.

During the wrapping process, the machine may also apply heat or pressure to the film to increase its adhesion, while sensors ensure that the film is correctly tensioned and wrapped. Once the wrapping process is complete, the product is released from the turntable or conveyor, and the machine can be reloaded with the next product.

To ensure continued operation of the used stretch wrap machine, regular maintenance and cleaning are necessary. This includes periodic inspection and replacement of worn or damaged parts, as well as cleaning of the machine's moving parts to prevent damage and ensure smooth operation.

In conclusion, the process of a used stretch wrap machine includes selecting the right machine, installation, configuration, loading, wrapping, and maintenance. With the appropriate settings and regular upkeep, this equipment can help to streamline the packaging process and ensure that products are protected during shipment and handling.

How to use "used stretch wrap machine"

A used stretch wrap machine is a machine used in warehouses, factories, and shipping centers to wrap pallets and protect goods during transportation. It's an economical way to ensure the safety of products during transit. To use a used stretch wrap machine:

1. Firstly, make sure that the machine is properly assembled and all the parts are in their respective places.

2. Turn on the machine and adjust the settings according to the type of goods that need to be wrapped. These can include the speed, tension, and wrapping patterns.

3. After adjusting the settings, place the pallet of goods in the designated area on the machine.

4. Start wrapping the pallet by pulling the stretch wrap from the dispenser and wrapping it over the top of the box or wrapping the entire pallet depending on the packaging standard.

5. The machine will continue to wrap the pallet automatically until it reaches the pre-set wrapping count, or you can set the wrapping count manually depending on the packaging requirement.

6. Once the wrapping is finished, the stretch wrap can be cut using a built-in cutter.

7. The wrapped pallet is now ready to be moved to a staging area or shipped to its final destination.

In summary, using a used stretch wrap machine is a simple process. Just follow the instructions and safety guidelines provided by the manufacturer, and be sure to maintain the machine regularly to ensure that it operates efficiently. Used stretch wrap machines can be an affordable way for businesses to improve their packaging processes and protect their goods during transit.

List Properties of "used stretch wrap machine"

A used stretch wrap machine typically has several properties that make it an attractive option for companies looking for cost-effective packaging solutions.

One of the most obvious benefits of a used stretch wrap machine is its lower cost compared to purchasing a new machine. This can be especially appealing for smaller businesses or those with budget constraints. Additionally, used machines are often readily available, which can help speed up the procurement process and get the new packaging equipment up and running more quickly.

Another advantage of a used stretch wrap machine is its potential durability. Many machines are built to last and can provide years of reliable performance, even after being used for long periods of time. This can offer significant value for companies that need a reliable packaging solution but don't want to invest in brand new equipment.

Furthermore, used stretch wrap machines are often versatile and can be used to package a wide range of products and materials. Many machines can handle various types of wrap films, including polyethylene, PVC, and other materials. They can also be used to wrap different types of products, from boxes and pallets to irregularly shaped items.

When considering a used stretch wrap machine, it's important to assess the machine's overall condition. This includes looking at the machine's age, maintenance history, and any potential wear or damage to key components. A reputable seller or dealer can provide this information and help ensure that the machine is in good working order before purchase.

Overall, a used stretch wrap machine can offer many benefits for companies looking for a cost-effective and reliable packaging solution. With proper maintenance and care, these machines can continue to provide value and improve operational efficiency for years to come.

List "used stretch wrap machine" FAQ

1. What is a stretch wrap machine?

A stretch wrap machine is a device that is used to wrap pallets and other large objects with stretch film to secure and consolidate them for transportation or storage.

2. What are the benefits of using a stretch wrap machine?

Stretch wrap machines provide many benefits, including increased efficiency, reduced labor costs, improved load stability, and reduced damage to products during transport.

3. What types of stretch wrap machines are available?

There are several types of stretch wrap machines available, including semi-automatic, automatic, and robotic stretch wrap machines.

4. What is the difference between semi-automatic and automatic stretch wrap machines?

Semi-automatic stretch wrap machines require some manual input from an operator, while automatic machines are fully automated, requiring no operator involvement.

5. How do I know which stretch wrap machine is right for me?

The type of stretch wrap machine you need will depend on your specific requirements. Factors to consider include the amount of goods you need to wrap, the frequency of use, and your budget.

6. Can I use used stretch wrap machines?

Yes, used stretch wrap machines are available and can provide a cost-effective solution for those on a budget. However, it is important to ensure that the machine has been properly maintained and is in good condition before purchasing.

7. What should I look for when buying a used stretch wrap machine?

When buying a used stretch wrap machine, it is important to consider factors such as the machine's age, condition, and maintenance history. It is also important to ensure that the machine meets your specific requirements.

8. Do I need training to use a stretch wrap machine?

Yes, it is recommended that operators receive proper training on the use of stretch wrap machines to ensure safe and efficient operation.

9. How often should I perform maintenance on my stretch wrap machine?

Regular maintenance is important to ensure that your stretch wrap machine operates properly and lasts for many years. It is recommended that maintenance be performed at least once a year, or more frequently if the machine is used frequently.

10. Where can I purchase a used stretch wrap machine?

Used stretch wrap machines can be purchased from equipment dealers, online marketplaces, or directly from other businesses that are selling their used equipment.