List Technical Parameters of “vacuum coating machine”

Vacuum coating machines are used in a wide range of industries for various coating applications. These machines operate in a vacuum environment, which allows for precise and consistent deposition of coatings onto the substrate. The technical parameters of vacuum coating machines mainly include the following:

1. Vacuum Chamber: It refers to the main chamber of the vacuum coating machine where the substrate is placed for coating. The vacuum chamber is made up of high-quality stainless steel and can withstand high vacuum levels.

2. Vacuum Pumps: The vacuum pumps are used to create and maintain the required vacuum levels in the vacuum chamber. There are different types of vacuum pumps used in vacuum coating machines, including rotary vane pumps, diffusion pumps, and cryogenic pumps.

3. Coating Source: The coating source is the material used to create the coating. The most common coating sources used in vacuum coating machines are evaporation sources, sputtering targets, and electron beam sources.

4. Substrate Holder: The substrate holder is used to hold the substrate in place during the coating process. The substrate holder can be customized to fit different substrates sizes and shapes.

5. Power Supply: The power supply is used to provide the necessary power to the coating sources. The type of power supply used depends on the type of coating source used in the vacuum coating machine.

6. Control System: The control system is used to control and monitor various parameters during the coating process, such as vacuum level, substrate temperature, coating thickness, and deposition rate.

7. Gas System: The gas system is used to introduce various gases into the vacuum chamber during the coating process, such as argon, oxygen, nitrogen, and hydrogen.

In summary, vacuum coating machines are complex pieces of equipment that require a range of technical parameters to deliver optimal results. These parameters include the vacuum chamber, vacuum pumps, coating source, substrate holder, power supply, control system, and gas system.

List Product features of “vacuum coating machine”

A vacuum coating machine is a type of equipment for deposition of thin films on surfaces. Various technologies can be used for vacuum coating, such as physical vapor deposition (PVD), chemical vapor deposition (CVD), or plasma-enhanced chemical vapor deposition (PECVD). The specific features of a vacuum coating machine depend on the technology used, as well as the size, configuration, and options of the machine. However, some common product features of a vacuum coating machine include:

1. Vacuum chamber: a closed vessel where the deposition process takes place under reduced pressure or vacuum. The size and shape of the chamber can vary depending on the application and the substrate size.

2. Deposition sources: the devices that generate and direct the flux of atoms or molecules towards the substrate. Depending on the technology used, the sources can be thermal evaporation crucibles, electron beam guns, sputtering targets, or plasma sources.

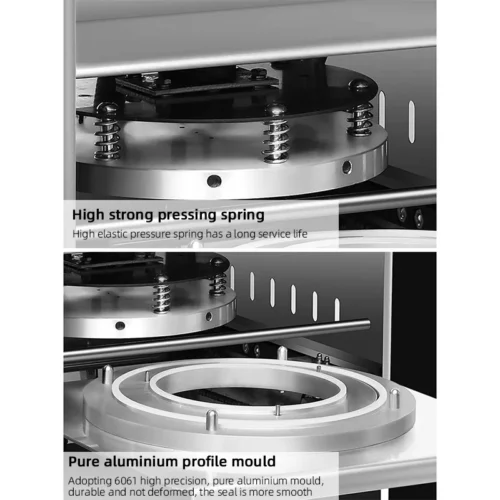

3. Substrate holder: the mechanism that supports and moves the substrate inside the vacuum chamber. The holder can be designed for single or multiple substrates, and it can have various motion modes, such as rotation, tilt, or linear translation.

4. Vacuum pumps and gauges: the components that control the pressure and gas composition inside the vacuum chamber. The vacuum pumps can be turbomolecular, diffusion, or cryogenic pumps, while the gauges can be ionization or thermal conductivity gauges.

5. Heating and cooling systems: the tools that control the temperature of the deposition sources and the substrate. The heating can be resistance, induction, or radiant heating, while the cooling can be water or gas cooling.

6. Process control and monitoring: the devices that regulate and measure the deposition parameters, such as deposition rate, thickness, and uniformity. The control systems can be manual or automated, and they can include power supplies, mass flow controllers, or optical monitors.

7. Auxiliary equipment: the optional components that enhance the performance or versatility of the vacuum coating machine. These can include plasma cleaning systems, ion sources, optical filters, or substrate cleaning stations.

Overall, a vacuum coating machine provides a versatile and precise tool for the creation of functional or decorative thin films on various materials, such as metals, semiconductors, ceramics, or polymers. The product features of a vacuum coating machine can affect the quality, efficiency, and cost of the deposition process, and they should be selected according to the specific needs and requirements of the users.

List Application of “vacuum coating machine”

Vacuum coating machines are versatile and useful machines that are utilized in different industries for various purposes. Here are some of the applications of a vacuum coating machine:

1. Electronics and semiconductors – Vacuum coating machines are extensively used in the electronics field to coat electronic components with metallic and insulating materials. It also helps to improve the electrical conductivity, thermal stability, and corrosion resistance of the electronic device.

2. Optics industry – Optics industry uses vacuum coating machinery to apply coatings like metal or dielectric layers onto glass surfaces to maintain the reflectivity of mirrors, camera lenses, broadband filters, mobile phone screens, LED lighting, and other optical systems.

3. Automotive Industry – Vacuum coating machine plays an essential role in the automotive industry. The machines deposit various types of coatings like chromium, aluminum, titanium, and ceramics on car parts to improve their wear and corrosion resistance, and UV stability. It also gives a glossy and smooth finish to vehicle exteriors and interiors.

4. Medical industry – Vacuum coating is useful for medical devices that come into contact with biological fluids. It provides anti-microbial coatings that prevent the growth of bacteria and assist in sterilization.

5. Aerospace industry – Vacuum coating machines are crucially used in making aircraft parts and components. The process provides a protective layer like Teflon or Parylene that resists wear, friction, and corrosion.

6. Packaging industry – Coatings, like metal and CVD, can be applied to packaging materials like plastic containers and bottles to make them stronger, corrosion-resistant, scratch-resistant, and attractive to buyers.

The above-listed applications are just a few of the many benefits that vacuum coating machines offer to the industry. Its ability to enhance the durability, toughness, and aesthetics of different materials makes it an essential tool for modern-day technology.

List Various Types of “vacuum coating machine”

Vacuum coating machines are designed to deposit thin films on substrates to enhance their surface properties, such as hardness, corrosion resistance, and wear resistance. There are various types of vacuum coating machines that can be used for different applications. Some of the common types of vacuum coating machines are:

1. Thermal Evaporation: In this coating technique, the material is evaporated by heating it in a vacuum chamber, and then it condenses onto the substrate to form a thin film.

2. Sputtering: This technique uses an argon plasma to bombard the target material, causing it to eject atoms, which then deposit on the substrate to form a thin film.

3. Chemical Vapor Deposition (CVD): In CVD, a gas is introduced into the vacuum chamber, which reacts with the substrate to form a thin film. This technique is commonly used to deposit materials like silicon, diamond, and other high-performance coatings.

4. Ion-Assisted Deposition (IAD): The IAD technique uses ion bombardment to enhance the adhesion and improve the physical properties of the deposited film. The films deposited using IAD have improved properties such as enhanced wear resistance and corrosion resistance.

5. Magnetron Sputtering: This technique employs a magnetic field to enhance the arc discharge between two targets, causing them to eject atoms, which then deposit on the substrate to form a thin film.

6. Plasma-Enhanced Chemical Vapor Deposition (PECVD): PECVD involves adding plasma to the CVD process, causing it to generate a high-energy reaction that can enhance the deposition rate and change the physical properties of the deposited film.

7. Electron Beam Evaporation: In this coating technique, a high-energy electron beam is used to evaporate the target material, enabling the deposition of materials that have a high melting point, such as refractory metals.

In conclusion, vacuum coating machines play a crucial role in various industries, from semiconductors to aerospace. The choice of the right vacuum coating machine for a specific application depends on factors such as the desired properties of the coated substrate, the material to be deposited, and the coating thickness.

List The Process of “vacuum coating machine”

A vacuum coating machine is a tool used for applying thin films on various materials in a vacuum environment. The process involves various stages which include preparation, deposition, and post deposition.

The first stage is preparation, which involves cleaning and drying the surface of the substrate to be coated. This stage ensures that the substrate is free of any contaminants that might interfere with the adhesion of the coating. The substrate is heated to a specific temperature to improve adhesion.

The deposition stage is the core of the process. It begins with the introduction of the vapors of the coating material into a vacuum chamber. The coating material is heated until it evaporates, allowing the molecules to move freely in the chamber. The vapors are then condensed onto the substrate, forming a thin film. The thickness of the coating can be controlled by adjusting the temperature of the material.

The post-deposition stage involves cooling and releasing the coated substrate from the chamber. The substrate is cooled to a specific temperature to ensure that the film adheres properly. The vacuum is then released, and the coated substrate is removed from the chamber.

During the entire process, the vacuum is maintained at a specific pressure range to ensure that the deposition is carried out under controlled conditions. The pressure in the vacuum chamber is measured using a vacuum gauge, and any deviation from the optimal range is corrected by adjusting the gas flow rate.

Vacuum coating machines use various deposition techniques, including thermal evaporation, sputtering, and plasma-enhanced deposition. These techniques use different deposition sources and conditions to ensure that the desired coating characteristics are achieved.

In conclusion, the vacuum coating machine is a versatile tool for applying thin films in a controlled environment. The preparation, deposition, and post-deposition stages are critical to achieving high-quality coatings with specific properties. The choice of deposition technique depends on the desired coating characteristics and the material being coated.

How to use “vacuum coating machine”

A vacuum coating machine is a tool used to apply a thin layer of coating onto a substrate surface. The coating is usually a thin metal layer that provides a decorative or functional effect. The vacuum coating machine works by evaporating a metal source material inside a vacuum chamber, which then condenses onto the substrate surface to form a thin film.

To use the vacuum coating machine, the first step is to clean the substrate surface thoroughly to remove any debris or contaminants that may interfere with the coating process. The substrate is then loaded onto a fixture inside the vacuum chamber.

The next step is to pump down the vacuum chamber to create a vacuum environment. This is done by using a vacuum pump, which removes air and other gases from the chamber to achieve a high vacuum. Once the desired vacuum level is achieved, the metal source material is loaded into the evaporation source, which is usually made of tungsten or molybdenum.

The metal source material is then heated to a high temperature using an electron beam or a resistive heater. This causes the material to evaporate and form a vapor cloud inside the vacuum chamber. As the vapor condenses onto the substrate surface, it forms a thin metal layer.

The thickness of the coating layer can be controlled by adjusting various parameters, such as the temperature of the metal source material, the distance between the evaporation source and the substrate, and the deposition rate of the material. After the coating process is complete, the substrate is removed from the vacuum chamber and can be further processed or used as is.

In conclusion, a vacuum coating machine is a useful tool for applying a thin metal coating onto a substrate surface. It requires careful substrate preparation and operation under a high vacuum to achieve a high-quality coating layer.

List Properties of “vacuum coating machine”

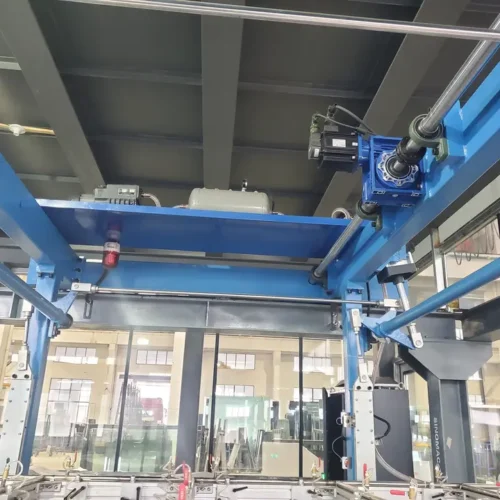

A vacuum coating machine is a type of equipment that uses a low-pressure environment to deposit thin layers of materials onto various surfaces. These machines are widely used in various industries, including electronics, aerospace, automotive, medical, and decorative coatings.

1) Chamber – The most essential component of a vacuum coating machine is its vacuum chamber. It is usually made of stainless steel and is designed to achieve a high vacuum level. The vacuum chamber is also equipped with heating and cooling systems, which allow the user to control the temperature of the chamber.

2) Deposition Sources – In a vacuum coating machine, the deposition source is a critical component. It is responsible for producing the thin film of material that will be deposited onto the surface. This source can be a solid or liquid material, and it can be ionized or evaporated to create a vapor during the deposition process.

3) Substrate Holder – The substrate holder is an essential part of the equipment as it holds the material that will be coated. The substrate holders are customizable and can be designed to hold different types and sizes of materials.

4) Pumps – The vacuum coating machines require different types of vacuum pumps to create a vacuum environment inside the chamber, such as Turbo pumps, rotary vane pumps, and diffusion pumps.

5) Monitoring Devices – A vacuum coating machine is equipped with monitoring devices such as vacuum gauges, pressure indicators, and flow meters. These devices are used to monitor the pressure, deposition rate, and flow of gases in the chamber.

6) PLC Control – Vacuum coating machines are controlled by Programmable Logic Controllers (PLCs). They monitor and automate different processes within the vacuum chamber, such as temperature control, process time, and deposition rate monitoring.

In conclusion, vacuum coating machines are complex systems that incorporate many different components and technologies. These machines are widely used in various industries, and their applications range from decorative coating to high-precision optical coatings. The key properties of vacuum coating machines are their vacuum chamber, deposition sources, substrates holder, pumps, monitoring devices, and PLC control.

List “vacuum coating machine” FAQ

FAQs:

1. What is a vacuum coating machine?

A vacuum coating machine is a specialized equipment used to apply thin films on various objects using a vacuum deposition process.

2. What is the vacuum deposition process?

Vacuum deposition is a process where a thin layer of material is deposited onto a surface in a vacuum environment. This can be achieved through a variety of techniques such as evaporation, sputtering, and ion plating.

3. What are the applications of vacuum coating machines?

Vacuum coating machines are used in a wide range of industries such as electronics, aerospace, automotive, medical, and optical industries. They are used for coating parts such as computer chips, solar panels, lenses, and mirrors.

4. What are the advantages of using a vacuum coating machine?

The main advantage of using a vacuum coating machine is that it allows for thin, uniform coatings to be applied to objects with high precision. It also enables the creation of complex coatings that cannot be achieved through traditional coating methods.

5. What materials can be deposited using a vacuum coating machine?

A wide range of materials can be deposited using a vacuum coating machine including metals, ceramics, polymers, and even biological materials.

6. What factors should be considered when choosing a vacuum coating machine?

Some factors to consider include the type of coating to be applied, the size of the parts to be coated, the required coating thickness, and the type of equipment needed for specific applications.

7. What safety measures should be taken when using a vacuum coating machine?

Some safety measures to take include wearing appropriate personal protective equipment, ensuring proper ventilation, and following manufacturer’s instructions.

Overall, vacuum coating machines are crucial tools in modern manufacturing and industrial processes. By applying thin layers of materials with high precision and accuracy, they enable the production of high-quality products with enhanced properties and features.