This machine is specially designed for vacuum packaging heavy bags, typically used for packing and vacuuming 25kg materials to produce brick-shaped final products. The packaging is clean and aesthetically pleasing, aiding in material preservation and storage.

Packing Sample:

Vacuum packaging bags are used.

Applications:

Suitable for various plastic insulation materials including Polyethylene, Polyvinyl Chloride, Cross-linked polyethylene, Cross-linked polyvinyl chloride, Low-smoke halogen-free polyolefin, and more. Also compatible with commonly used rubber insulation materials and various resins.

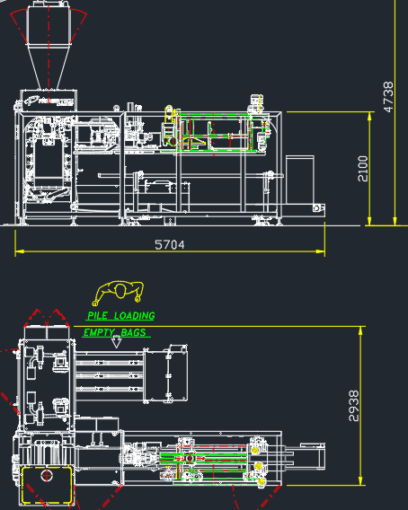

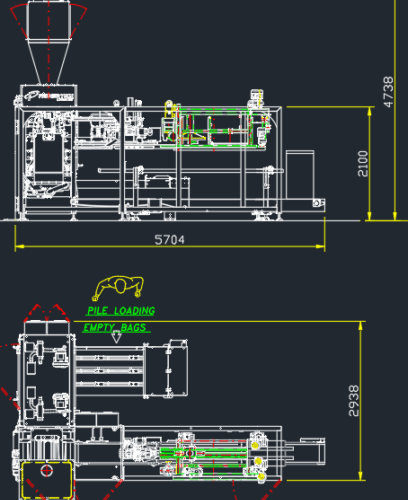

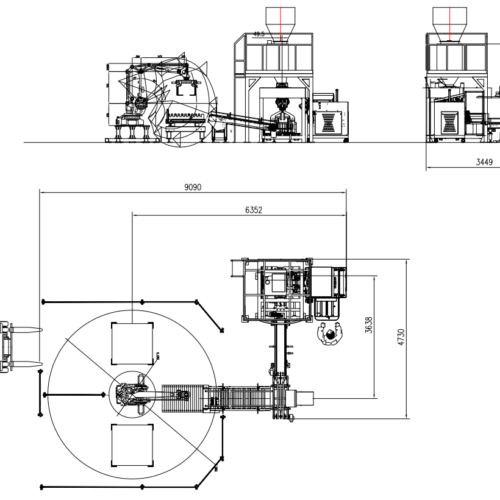

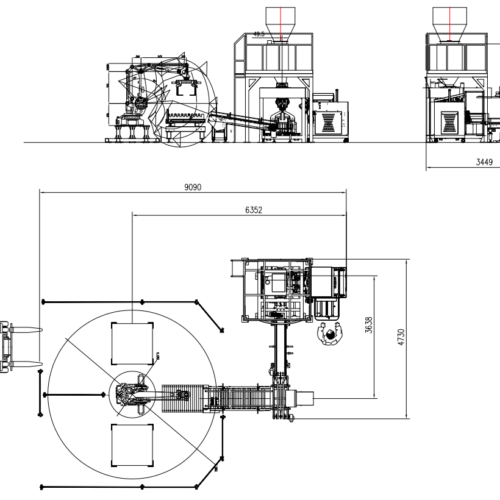

Working Process:

The machine operates by taking bags from storage, positioning, opening, weighing, filling, shaping, sealing, vacuuming, and palletizing.

Machine Details:

Weighing Scale Unit:

- Bucket type granular scale made of SUS304

- Features pneumatic control discharge and digital display

- Weighing accuracy of ±50g and a range of 20-40kg

Bag Storage Unit:

- Ensures one storage for one use with automatic switching

- Each storage holds a minimum of 40 bags

- Equipped with fixed slots for easy bag placement and retrieval

Bag Taking Mechanism:

- Uses vacuum suction cups to avoid bag surface damage

- Automatically retrieves bags with a cycle system

Bag Opening Mechanism:

- Utilizes vacuum suction cups to open bags without surface damage

- Interlocked with the bag taking mechanism for seamless operation

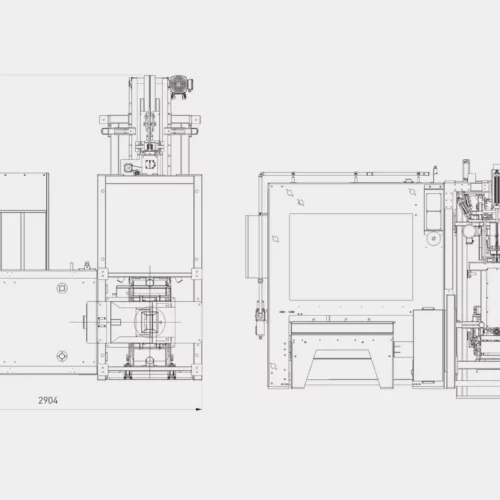

Shaping Mechanism:

- Ensures bags are formed into brick shapes with adjustable sizing

Vacuum Pumping and Sealing Mechanism:

- Features an oil-free vacuum pump for efficient sealing

- Seals with a width of at least 15mm and temperature control range of 0-200℃

Conveying Mechanism:

- Conveyor belt with material turnover mechanism for horizontal placement

- Equipped with herringbone design for smooth operation and photoelectric induction

Technical Parameters:

- Model: FP-1012-VACC

- Packing speed of 2 bags/min

- Material characteristics include compatibility with various bag sizes and thickness

Equipment Material:

- Parts in contact with materials made of stainless steel SUS304L

Component Configuration:

- Includes automatic weighing scale, bag feeding mechanism, sealing mechanism, and more

Factory Gallery showcases the equipment’s manufacturing setup.

Related Posts:

- 50 kg Bag Packing Machine

- 25kg Open Mouth Bagging Machine for Powder

- Heavy Bag Packaging Machine

- Automatic 25kg Bagging Machine