List Technical Parameters of "yogurt filling machine"

Yogurt filling machines are high-performance machines that are designed to accurately fill cups with yogurt at a rapid pace. They are designed in such a way that they can fill cups with a wide variety of yogurts, including plain, flavored, and strained yogurt.

Here are some of the technical parameters of a yogurt filling machine:

1) Capacity: This is one of the main technical parameters of a yogurt filling machine. The capacity of the machine is determined by the number of cups it can fill per minute. These machines can fill hundreds or thousands of cups per hour depending on their size and capacity.

2) Accuracy: Yogurt filling machines are designed to fill cups with a high degree of accuracy. This means that they can fill cups with a consistent amount of yogurt, ensuring that each cup has the same quantity of product.

3) Filling speed: The filling speed of a yogurt filling machine refers to the rate at which the machine fills cups with yogurt. These machines can fill cups at different speeds, ranging from 30 cups per minute to over 200 cups per minute.

4) Cup size: Yogurt filling machines can handle cups of different sizes. This means that the machine can adjust to fill cups of different diameters and heights.

5) Cleaning and Maintenance: A good yogurt filling machine is designed with ease of cleaning and maintenance in mind. The machine features parts that can be easily removed and cleaned to ensure hygienic filling.

6) Material of construction: Yogurt filling machines are usually made from high-quality stainless steel. This material is durable, easy to clean, and resistant to corrosion and wear.

7) Power consumption: The power consumption of a filling machine varies depending on the size and capacity of the machine. Some machines may require more power to operate than others.

8) Dispensing system: The dispensing system of a yogurt filling machine is designed to ensure that the yogurt is dispensed smoothly and accurately into each cup. This helps to prevent waste and ensure that each cup is filled with the same amount of yogurt.

Overall, yogurt filling machines are an essential tool for dairy producers who want to ensure that their yogurt products are filled accurately, quickly, and hygienically. These machines are designed to operate with a high degree of precision, making them an essential tool for production processes.

List Product features of "yogurt filling machine"

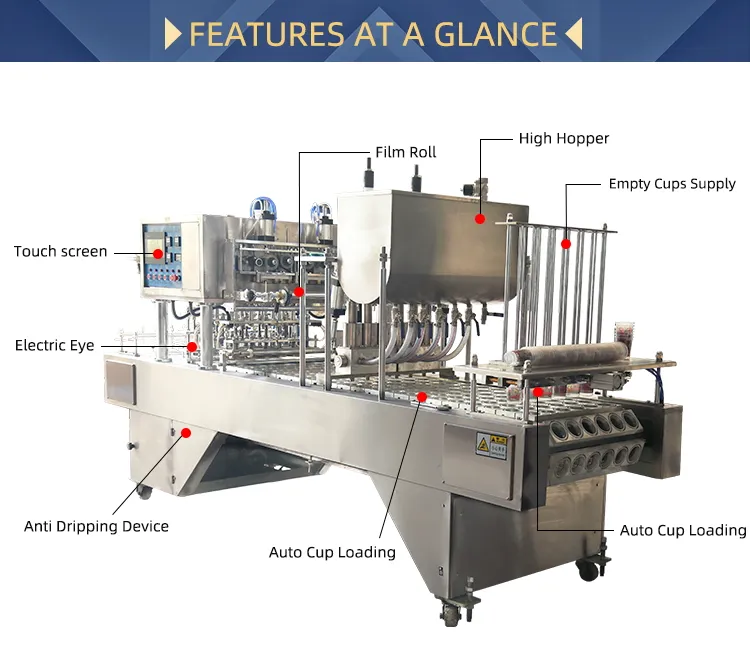

A yogurt filling machine is a specialized equipment used in the food industry for packaging and filling yogurt into various containers. This machine is designed to fill and seal yogurt products accurately, quickly, and with minimal human intervention. Some of the essential product features of a yogurt filling machine include:

1. Accurate filling: A yogurt filling machine is designed to fill the containers accurately to the desired level. This is achieved by using advanced sensors and controls that ensure that each container is filled with the same amount of yogurt.

2. Variable filling speed: Depending on the size and type of container, the filling speed can be adjusted to ensure efficient filling while maintaining the product's quality.

3. Material compatibility: Yogurt filling machines are made of high-quality materials that are resistant to corrosion and do not react with the yogurt, ensuring the product's safety and purity.

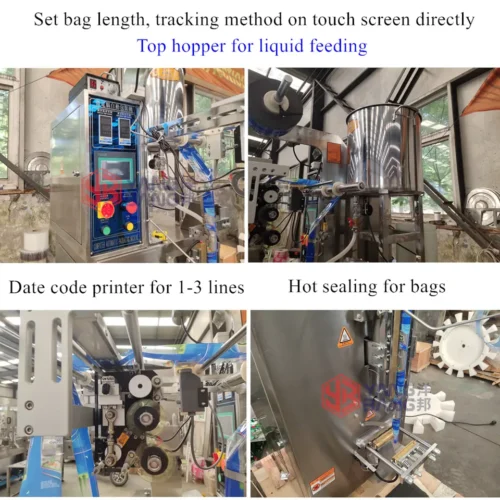

4. Easy to operate: A yogurt filling machine comes with user-friendly controls that require minimal training to operate. Some machines come with touchscreen displays that provide easy access to the machine's functions and settings.

5. Easy to maintain: The machine is easy to clean and maintain, reducing downtime and increasing productivity.

6. Multiple container sizes: The machine can accommodate various container sizes, shapes, and materials, allowing manufacturers to package yogurt in different formats.

7. Sealing options: Yogurt filling machines can seal containers using different sealing options such as foil sealing, plastic sealing, or heat sealing.

8. High productivity: A yogurt filling machine can fill and seal thousands of containers per hour, making it a highly productive machine.

9. Food grade standards: Yogurt filling machines are built to meet food grade standards and regulations, ensuring that the product is safe for human consumption.

10. Customization options: Depending on the manufacturer's specific requirements, the machine can be customized to meet their needs, such as adding extra filling heads or adjusting the filling speed.

List Application of "yogurt filling machine"

The yogurt filling machine is an essential piece of equipment used in the food and beverage industry. This machine is designed to fill containers with yogurt, ensuring that the product is accurately and efficiently packaged. The following are some of the applications of this machine.

1. Yogurt production: Yogurt filling machines are commonly used in the production of yogurt. They are used to fill plastic, glass, or ceramic containers with the yogurt. The machine ensures that the containers are filled with the right amount of yogurt and that the packaging is hygienic and safe for consumption.

2. High volume yogurt packaging: Yogurt filling machines are designed to handle a high volume of yogurt packaging. This machine's speed and accuracy enable food manufacturers to package large quantities of yogurt quickly and efficiently.

3. Automated yogurt packaging: Yogurt filling machines are capable of automating the yogurt packaging process. By using this machine, yogurt production companies can reduce labor costs while significantly increasing production capacity.

4. Preparation of yogurt-based products: Yogurt filling machines can be used in the preparation of yogurt-based products such as frozen yogurt, smoothies, and fruit mixtures. The machine ensures that the ingredients are evenly mixed and packaged in a hygienic container for delivery to retail stores.

5. Reduced product waste: Yogurt filling machines are designed to minimize the amount of product waste. Packaging errors that occur due to human error or inconsistency are reduced or eliminated with the use of this machine.

6. Accurate filling of containers: Yogurt filling machines accurately fill containers with yogurt, ensuring that each container has the same volume of product. This accuracy ensures that customer satisfaction is achieved consistently.

7. Ease of cleaning: Yogurt filling machines are easy to clean, thanks to their streamline design. They can be cleaned and sanitized quickly and efficiently, allowing for the production of high-quality yogurt.

In conclusion, the yogurt filling machine has several applications in the food and beverage industry, including high volume yogurt packaging and production, automated packaging, preparation of yogurt-based products, accurate filling of containers, reduced product waste, and ease of cleaning. These benefits make the yogurt filling machine a critical component in the food manufacturing process.

List Various Types of "yogurt filling machine"

1. Semi-automatic yogurt filling machine:

This type of machine is designed to help small and medium-sized yogurt producers with their filling needs. It can fill pre-determined amounts of yogurt in cups, bottles, or pouches.

2. Fully automatic yogurt filling machine:

This type of machine is designed to help large-scale yogurt producers. It can fill and package hundreds of yogurts per minute, eliminating the need for manual intervention.

3. Cup filling and sealing machine:

This machine is designed to fill yogurt into cups and seal them with a lid. It can be used for small-scale yogurt production. It can handle various cup sizes and shapes.

4. Pouch filling machine:

This machine is designed to fill and seal yogurt in pouches. It can handle different sizes and shapes of pouches and fill them with precisely measured amounts of yogurt.

5. Rotary filling machine:

This machine is designed for bulk yogurt production. It can fill and package large quantities of yogurts in a short period. It has multiple interchangeable nozzles to fill various cup sizes.

6. Inline filling machine:

This type of filling machine is designed to fill and package yogurt in a continuous flow process. It is highly accurate and efficient, ensuring consistent and precise filling of yogurts.

7. Piston filling machine:

This machine is designed to fill yogurt into containers using a piston mechanism. It can be used for low to medium-speed production lines and can handle a wide range of container sizes.

8. Auger filling machine:

This type of machine uses an auger mechanism to fill yogurt into containers. It can handle different viscosities of yogurt and can be used for both small and large-scale production.

9. Volumetric filling machine:

This machine fills yogurt based on preset volume levels. It can be used for high-speed filling in large-scale production lines and ensures uniform filling of every container.

In conclusion, the various types of yogurt filling machines serve different needs depending on the scale of production, container type, and yogurt viscosity. Yogurt producers need to understand their production requirements and yogurts' specific characteristics to select the most suitable filling machine.

List The Process of "yogurt filling machine"

The yogurt filling machine is a device that is used in the food and beverage industry to fill containers with yogurt quickly and efficiently. The process of filling yogurt using a machine involves several steps as outlined below:

1. Preparation: The first step in filling yogurt is the preparation of the machine. This involves cleaning and sanitizing the machine to ensure it is free from contaminants that may affect the quality and safety of the yogurt. The machine's parts are carefully inspected, and any worn out parts are replaced to ensure the machine runs smoothly.

2. Filling: The next step is filling the yogurt containers. Various types of containers can be used depending on the intended use, volume, and packing requirements. The machine can fill different sizes of yogurt containers, from small to large volumes. The yogurt is pumped into the containers using nozzles that are configured to control the flow rate, volume, and consistency of the yogurt.

3. Sealing: After filling, the containers are sealed using a sealing mechanism. Sealants are used to cover the yogurt to prevent contamination and maintain freshness. The sealing is done using various methods such as foil, lidding, or capping depending on the type of container used.

4. Labelling and coding: The yogurt containers are then labeled and coded to give the necessary information such as the manufacturer, expiry date, batch number, and ingredients. These details are printed on the containers using inkjet codes or labels.

5. Packaging: The last step involves packaging of the filled and labeled containers. The packaged products are then stored in refrigerated storage before being shipped off to retailers or customers.

In conclusion, the use of yogurt filling machines in filling yogurt containers is an essential process in the food and beverage industry. The machine ensures efficiency, safety, and consistency in the filling process, making it easier for manufacturers to meet production timelines and deliver quality products to their customers.

How to use "yogurt filling machine"

Yogurt filling machine is a specialized equipment that is primarily designed to fill and package yogurt in various containers such as cups, sachets, bottles, and jars. This machine is widely used in the food processing industry to automate the process of yogurt filling and packaging, hence improving efficiency and productivity.

Using a yogurt filling machine is quite simple, and it follows a few basic steps as outlined below:

1. Cleaning and Sterilization

Before using the machine, ensure that it is thoroughly cleaned and sterilized to prevent any form of contamination that can compromise the quality of the yogurt. Use hot water, steam, or cleaning detergents for cleaning and sanitization.

2. Preparing the Yogurt

Prepare the yogurt mixture, ensuring that it has the right consistency and flavor that meets the desired specifications.

3. Setting Up the Machine

Set up the machine by adjusting the filling volume, selecting the container size, and adjusting the temperature to the desired level. Fill in the yogurt mixture in the machine to get started.

4. Filling and Packaging

Turn on the machine and let it run to the set speed. The yogurt filling machine will automatically fill the containers with yogurt. The containers will then move to the packaging section where caps, seals, or lids are placed on them. The filled and packaged containers are then labeled and moved to storage or shipment.

5. Cleaning and Maintenance

After use, clean the machine again and conduct routine maintenance to ensure it is in excellent condition for the next use.

In conclusion, using a yogurt filling machine is simple and easy, and it can make the yogurt filling and packaging process fast and efficient while maintaining high standards of hygiene and quality.

List Properties of "yogurt filling machine"

The yogurt filling machine is a specialized equipment that is designed to accurately package yogurt products in cups or bottles. It has a number of properties that make it ideal for use in both small and large scale yogurt manufacturing. Some of the properties of the yogurt filling machine include the following:

1. Versatility: This filling machine has the ability to handle a variety of yogurt products including plain, flavored, and Greek yogurt. This makes it ideal for use in diverse production environments.

2. High Speed: The machine has a high production rate, capable of filling up to 200 cups or bottles per minute. This allows manufacturers to produce large quantities of yogurt in a short period of time.

3. Accuracy: The yogurt filling machine is known for its high level of accuracy when filling cups or bottles. It ensures that the exact amount of yogurt is dispensed consistently into each container.

4. Easy to Operate: This machine is easy to operate and does not require specialized training. With just a few simple steps, the appropriate amount of yogurt can be dispensed into the container.

5. Hygiene: The yogurt filling machine is designed to meet hygiene standards. It is made from food-grade materials and is easy to clean, ensuring that the yogurt product meets food safety regulations.

6. Automation: The machine can be fully automated, reducing the need for manual labor and increasing efficiency in the manufacturing process. Additionally, automation ensures accuracy and consistency in filling the containers.

7. Customizable: The yogurt filling machine can be customized to meet the unique needs of each manufacturer. This includes adjusting the number of filling nozzles and the volume of yogurt dispensed.

Overall, the yogurt filling machine is an essential piece of equipment for any yogurt manufacturer. Its properties make it efficient, accurate, and easy to use, which ultimately leads to higher production rates and consistent quality.

List "yogurt filling machine" FAQ

1. What is a Yogurt Filling Machine?

A Yogurt Filling Machine is a machine used to fill and package yogurt into containers. It is designed to automate the yogurt packaging process and increase production efficiency.

2. How does a Yogurt Filling Machine work?

A Yogurt Filling Machine works by filling yogurt into containers using high-precision filling nozzles. It then seals the containers to prevent contamination.

3. What are the benefits of using a Yogurt Filling Machine?

Yogurt Filling Machines offer numerous benefits, including increasing production efficiency, reducing labor costs, and improving product consistency. They also help maintain hygiene standards and reduce the risk of contamination.

4. What types of Yogurt Filling Machines are available?

There are various types of Yogurt Filling Machines available in the market, including automatic and semi-automatic filling machines. They come in different sizes and configurations to meet different production needs.

5. What factors should be considered when selecting a Yogurt Filling Machine?

When selecting a Yogurt Filling Machine, factors to consider include production volume, type and consistency of yogurt to be filled, container size, and budget.

6. Can a Yogurt Filling Machine handle different types of yogurt?

Yes, a Yogurt Filling Machine can handle different types of yogurt, including plain, flavored, and Greek yogurt. However, the machine must be configured to handle the consistency and thickness of the particular yogurt.

7. How can one maintain and clean a Yogurt Filling Machine?

To maintain and clean a Yogurt Filling Machine, it is important to follow the manufacturer's instructions for regular maintenance. Cleaning procedures may require disassembling and cleaning individual machine parts, including the nozzles and filling tube.

8. Are Yogurt Filling Machines expensive?

Yogurt Filling Machines can be expensive, depending on the size, configuration, and features. However, they offer a significant return on investment by increasing production efficiency and reducing labor costs.

9. Can a Yogurt Filling Machine be customized?

Yes, Yogurt Filling Machines can be customized to meet specific production needs. Customizations may include different filling heads, container sizes, and production capacity.

10. Do Yogurt Filling Machines come with a warranty?

Most Yogurt Filling Machines come with a warranty from the manufacturer. The length of the warranty varies depending on the machine model and manufacturer.