1. What is a quad seal bag packaging machine?

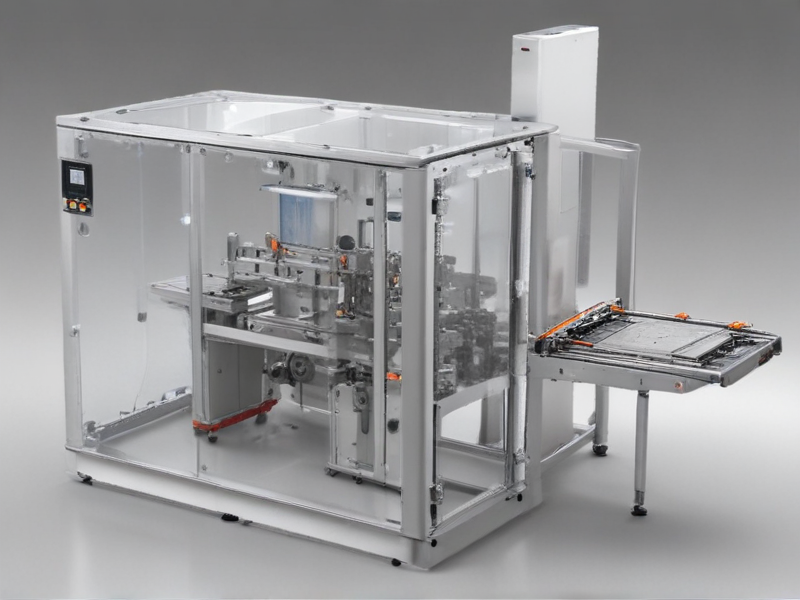

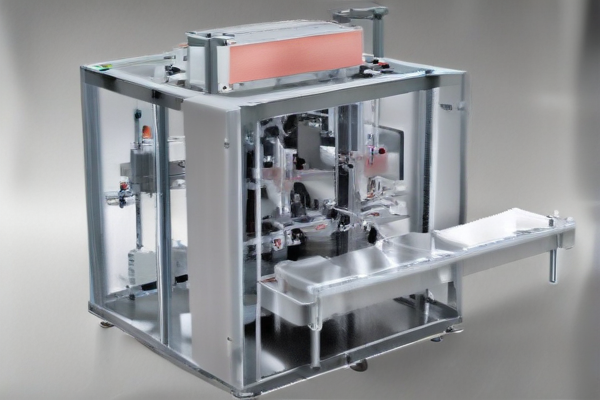

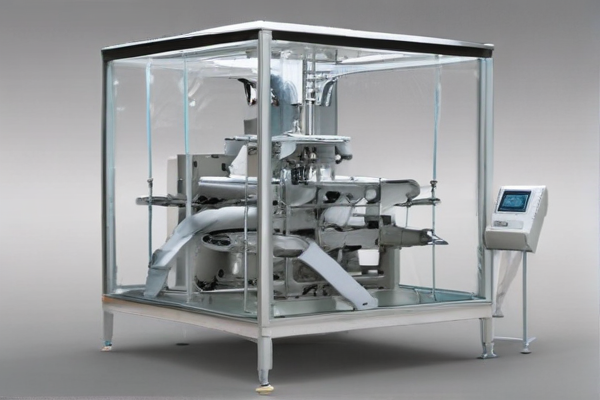

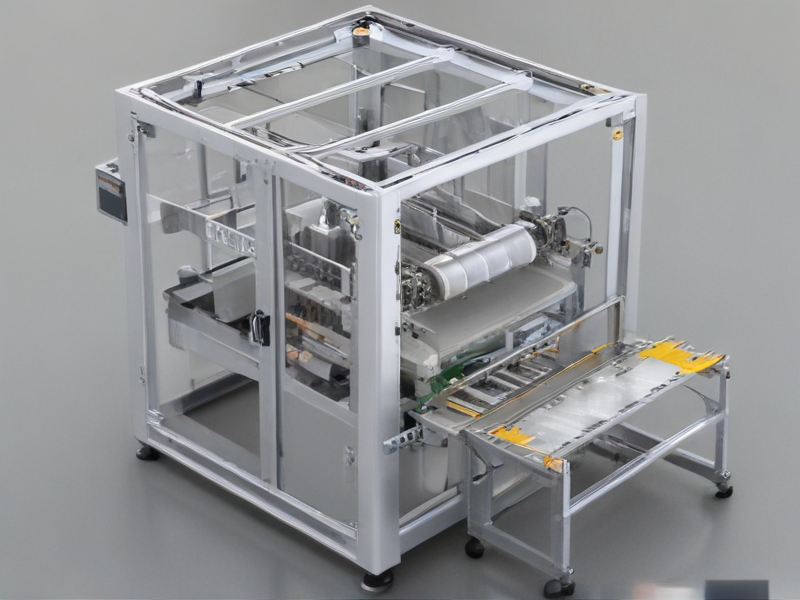

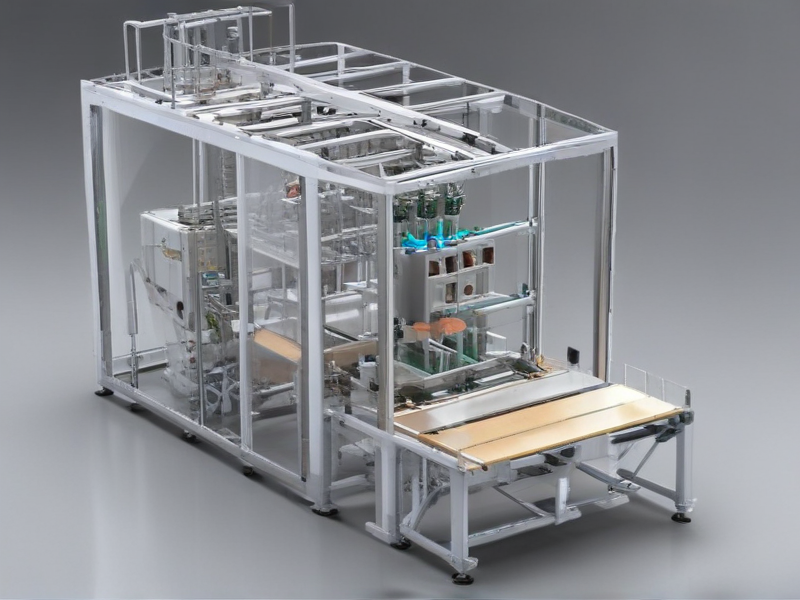

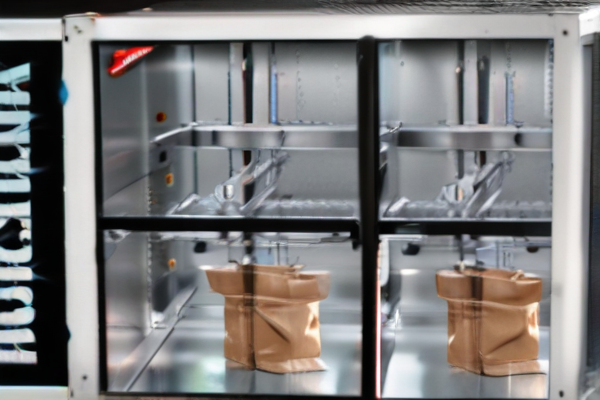

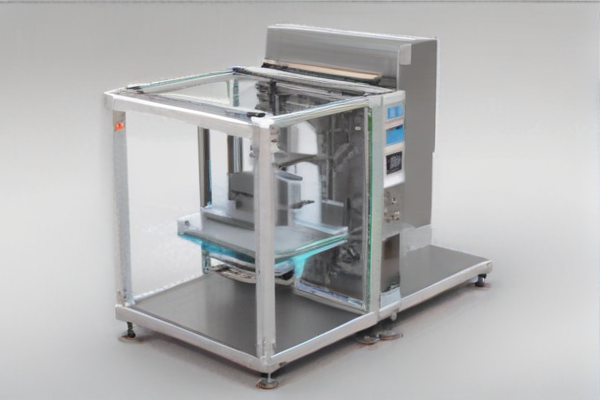

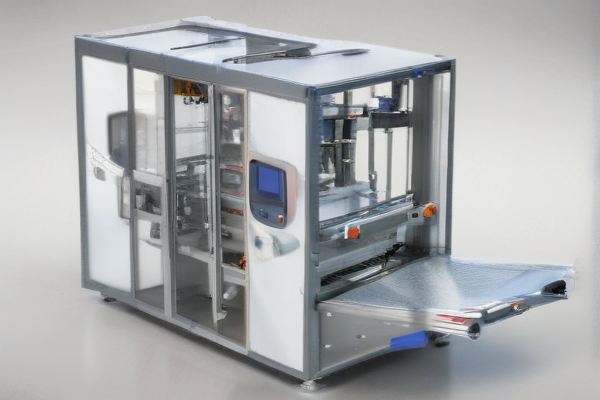

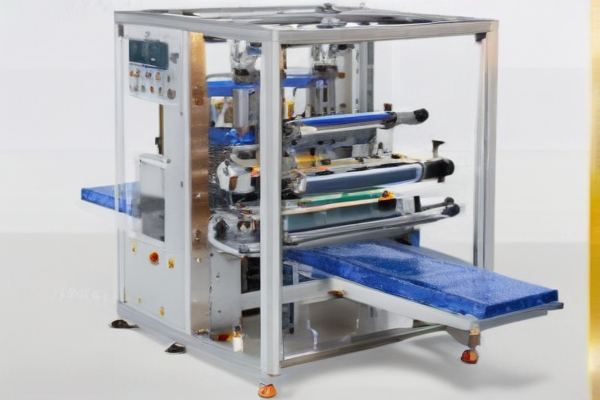

A quad seal bag packaging machine is specialized equipment designed to form, fill, and seal bags with four distinct vertical seals, providing a sturdy, square-shaped base that enables the bag to stand upright better.

2. What are the benefits of using a quad seal bag?

Quad seal bags offer enhanced product stability, optimal shelf presence, and improved packaging integrity, making them suitable for a wide range of products including food, pet food, and non-food items.

3. Why should I consider sourcing from SourcifyChina factory?

SourcifyChina factory offers competitive pricing, high-quality machines, reliable after-sales service, and extensive experience in manufacturing packaging equipment, ensuring you get value for your investment.

4. What specifications do I need to provide for a customized quad seal bag machine?

Key specifications include bag size range, production speed, type of materials to be used, and any additional features like print registration, gas flushing, or zippers.

5. How long does it take to manufacture and deliver the machine?

The manufacturing and delivery time typically ranges from 6 to 12 weeks, depending on the customization level and order quantity.

6. Is training provided upon installation?

Yes, SourcifyChina factory provides operational training and detailed manuals to ensure smooth installation and efficient machine operation.

7. What types of products can be packaged using a quad seal bag machine?

This machine can package a wide variety of products including coffee, grains, nuts, confectionery, pet food, detergents, and more.

8. How do I request a quotation from SourcifyChina factory?

You can request a quotation by contacting SourcifyChina factory directly via their website, email, or phone, providing details about your packaging needs and specifications.

9. What after-sales services are offered?

After-sales services include technical support, maintenance services, and spare parts supply to ensure ongoing machine efficiency and longevity.

10. Are there any certifications or quality assurances for the machines?

Yes, SourcifyChina factory machines comply with industry standards and certifications, ensuring reliability and high quality. Be sure to ask for specific certifications applicable to your region.