Sure, here are some FAQs related to the manufacturing of rollstock packaging machines at SourcifyChina factory:

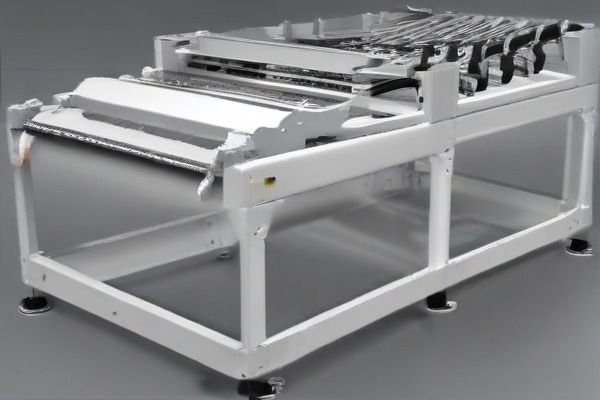

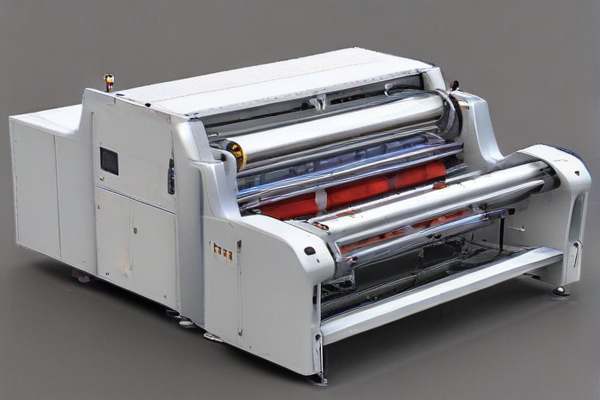

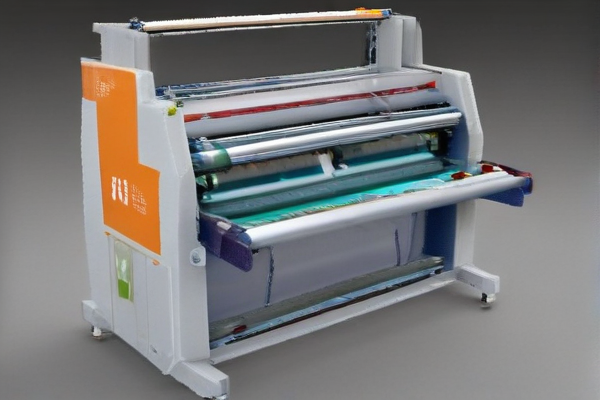

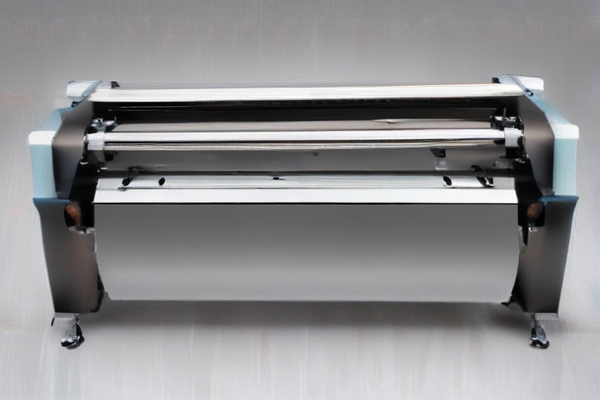

1. What is a rollstock packaging machine?

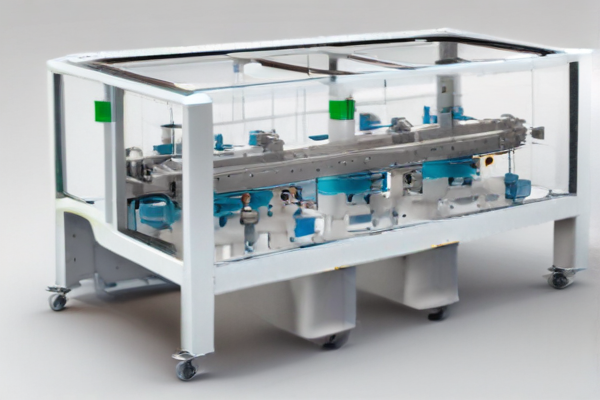

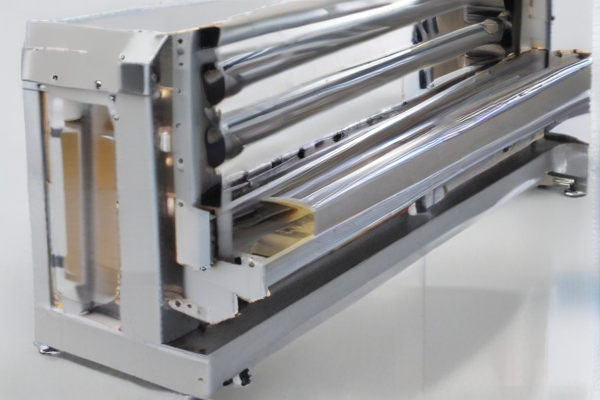

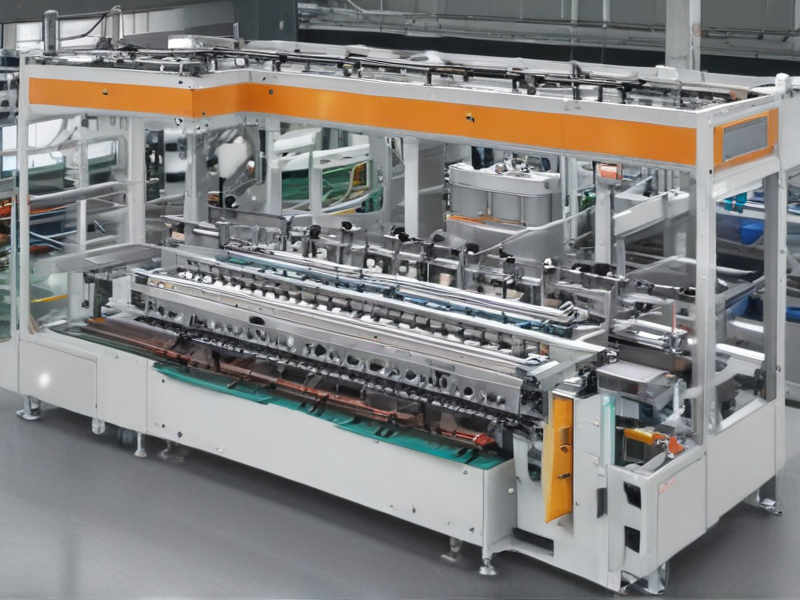

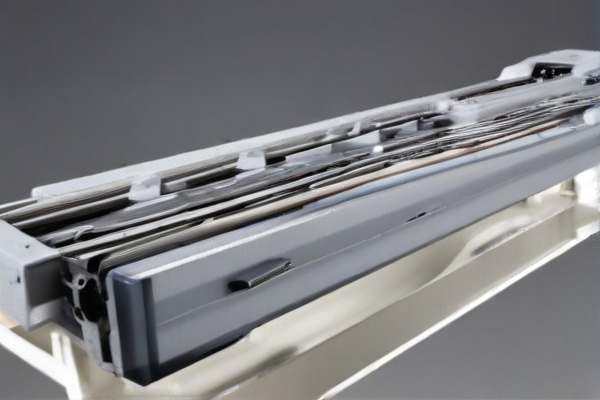

A rollstock packaging machine is a type of packaging equipment that forms, fills, and seals products using rollstock material. These machines are commonly used for packaging food, pharmaceuticals, and other consumables.

2. Why choose SourcifyChina for rollstock packaging machines?

SourcifyChina is renowned for its high-quality manufacturing standards, competitive pricing, and excellent after-sales support. They use advanced technology and experienced engineers to ensure each machine meets international quality standards.

3. What materials can the rollstock packaging machine handle?

The rollstock packaging machines from SourcifyChina can handle a variety of materials, including flexible films like polyethylene (PE), polypropylene (PP), and laminated materials.

4. What industries benefit from rollstock packaging machines?

Industries that benefit the most include food and beverage, pharmaceuticals, cosmetics, and consumer goods. The machines can package items such as snacks, dairy products, medical supplies, and more.

5. Are the machines customizable?

Yes, SourcifyChina offers customizable solutions to meet specific requirements, including different sizes, speeds, and packaging types to suit various industrial applications.

6. What is the typical lead time for manufacturing and delivery?

The typical lead time ranges from 8 to 12 weeks, depending on the level of customization and the current production schedule.

7. What kind of after-sales support does SourcifyChina offer?

SourcifyChina provides comprehensive after-sales support, including installation, training, maintenance, and troubleshooting services to ensure smooth operation.

8. How can I ensure the machine’s quality before purchasing?

SourcifyChina operates under strict quality control measures and provides detailed documentation, test results, and virtual factory tours upon request. They also offer customer references and sample packaging tests.

9. What are the warranty terms?

Typically, SourcifyChina offers a one-year warranty on parts and services. Extended warranties are available upon negotiation.

10. How can I place an order?

You can place an order by contacting SourcifyChina directly through their website, email, or phone. Consulting with their sales representatives can help customize your machine as per your specific needs.