Sure! Here’s a short FAQ focused on the quality and manufacturing process of rollstock packaging machines from SourcifyChina factory:

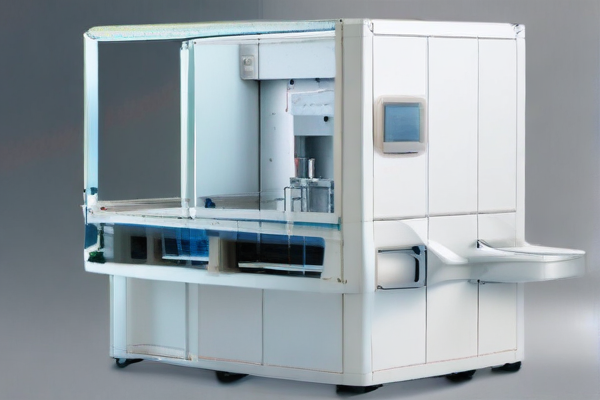

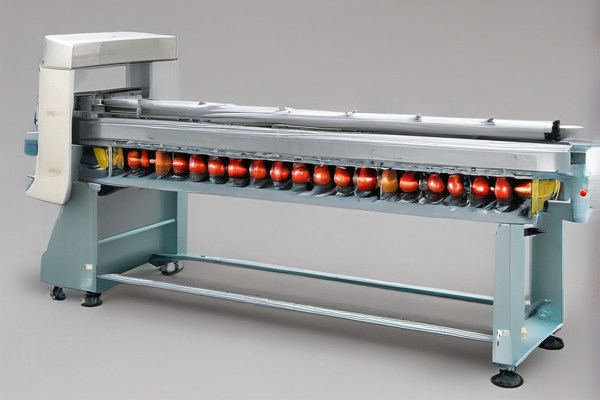

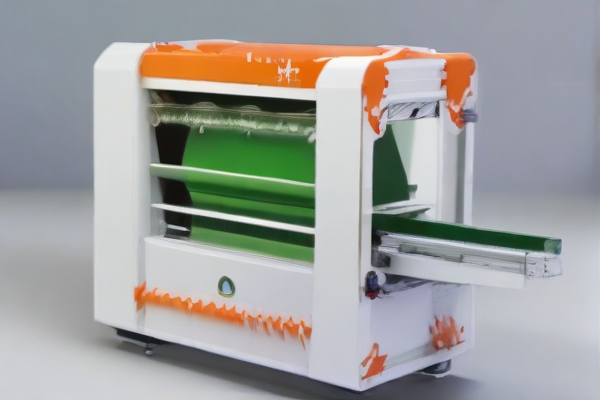

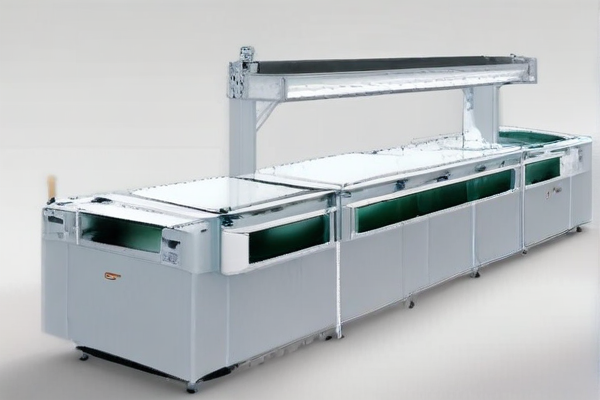

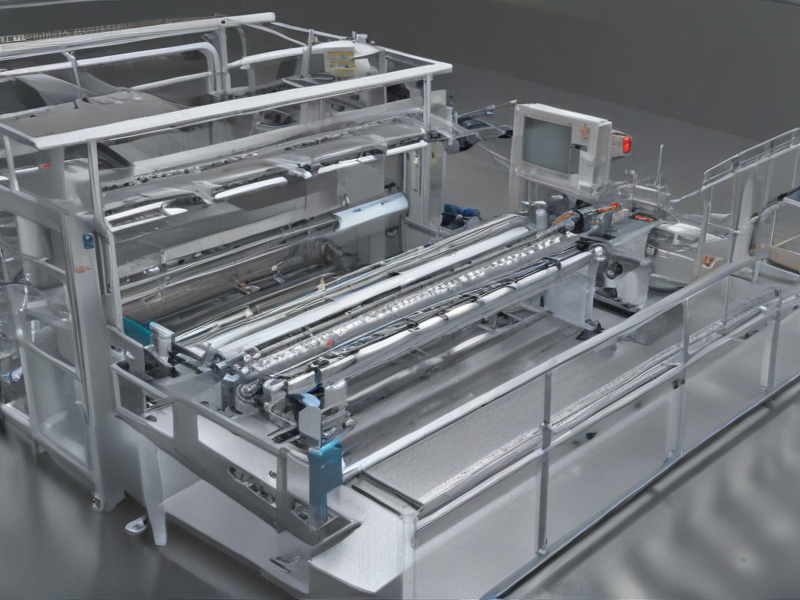

What is a rollstock packaging machine?

A rollstock packaging machine is equipment used in the packaging industry to form, fill, and seal products efficiently using rollstock material.

Why should I choose SourcifyChina factory for my rollstock packaging machine?

SourcifyChina factory is known for high-quality manufacturing standards, cutting-edge technology, and competitive pricing. Our experienced team ensures robust design and reliable performance for all machines.

What quality control measures does SourcifyChina implement?

We follow strict quality control protocols including material inspection, in-process checks, and final performance testing. This ensures each machine meets industrial standards and customer specifications.

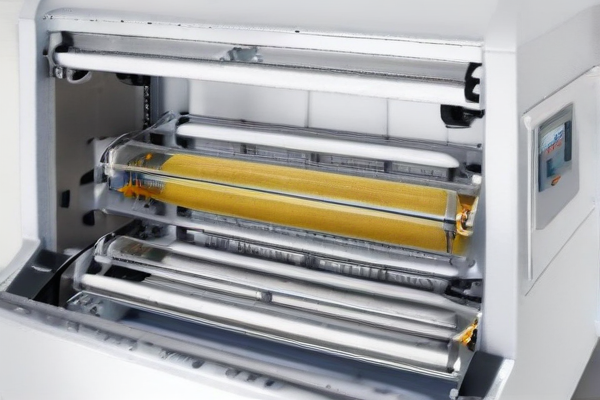

What materials are used in constructing the rollstock packaging machines?

Our rollstock packaging machines are constructed using high-grade stainless steel, aluminum, and other durable components to ensure longevity and reliability.

How does SourcifyChina ensure the durability of its rollstock packaging machines?

We use advanced manufacturing techniques, quality materials, and rigorous testing to ensure each machine can withstand long-term use and harsh working conditions.

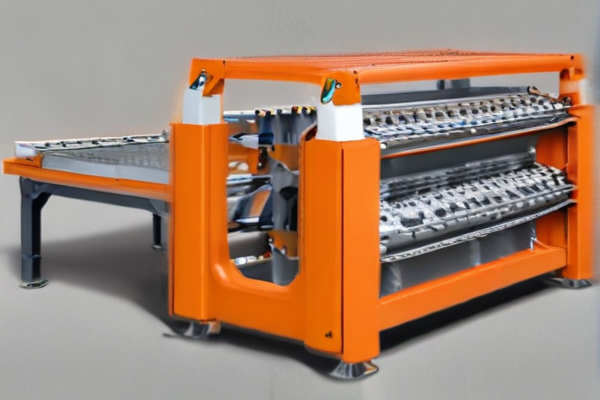

Can SourcifyChina customize rollstock packaging machines according to my requirements?

Yes, we offer customization options to meet specific requirements such as size, speed, and packaging material compatibility.

What kind of after-sales support does SourcifyChina offer?

We provide comprehensive after-sales support including installation assistance, operator training, and maintenance services to ensure your machine operates efficiently.

How long does it take to manufacture and deliver a rollstock packaging machine?

Lead times vary depending on the complexity and customization requirements. Typically, it takes about 6 to 8 weeks from order confirmation to delivery.

Is there a warranty on the rollstock packaging machines?

Yes, all our machines come with a warranty covering parts and labor to address any manufacturing defects or issues.

How can I place an order with SourcifyChina factory?

You can contact our sales team via email or phone. They will guide you through the ordering process, including customization options, pricing, and lead times.