Sure, here are some frequently asked questions (FAQ) along with their answers for manufacturing a rotary capping machine with quality work from SourcifyChina factory:

Q1: What types of rotary capping machines does SourcifyChina manufacture?

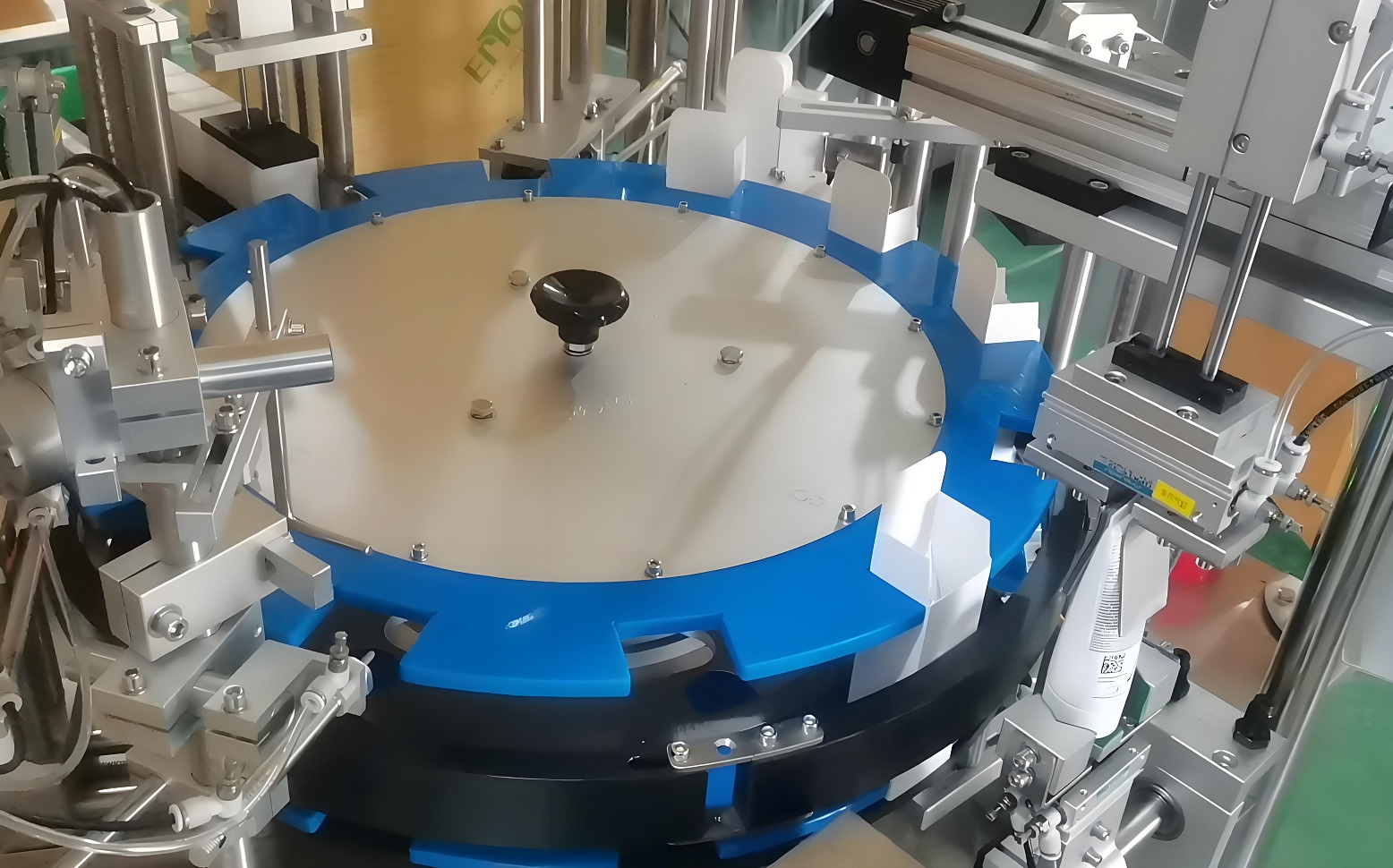

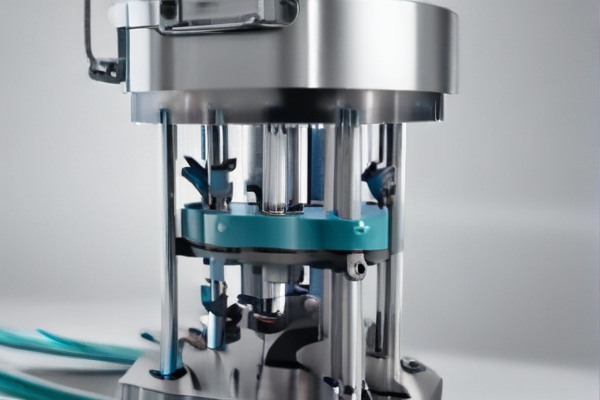

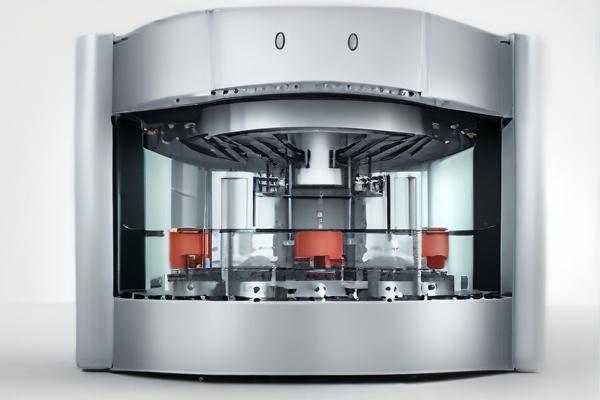

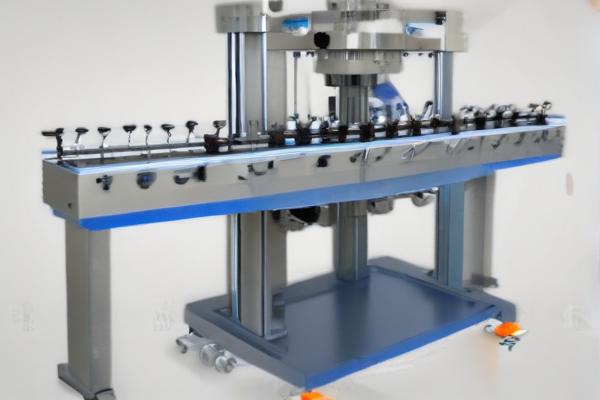

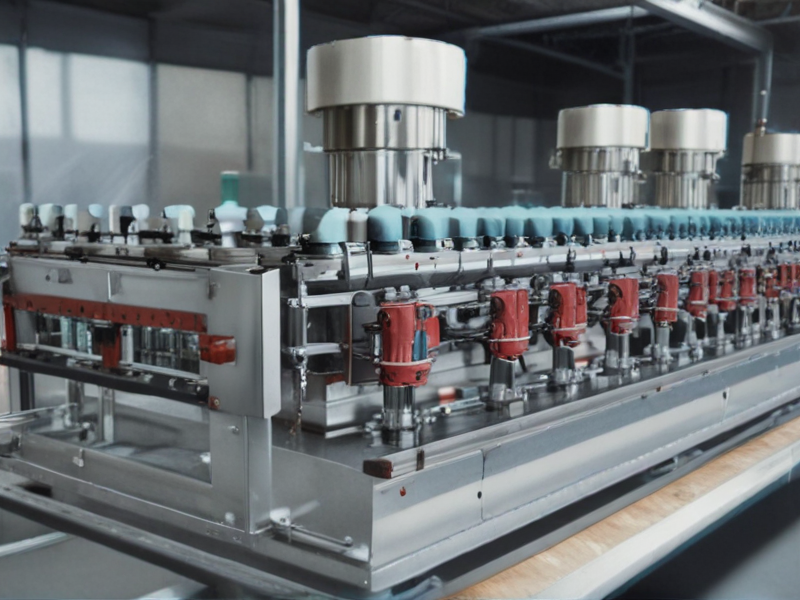

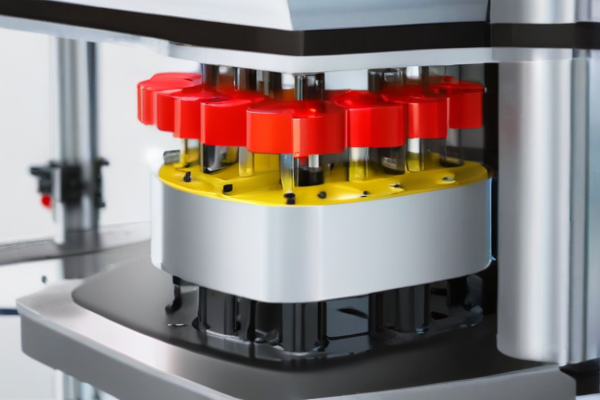

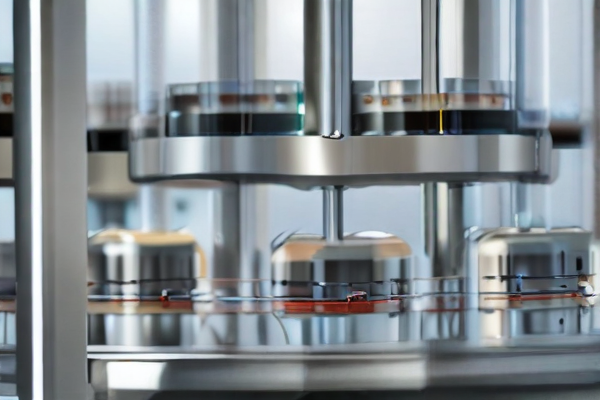

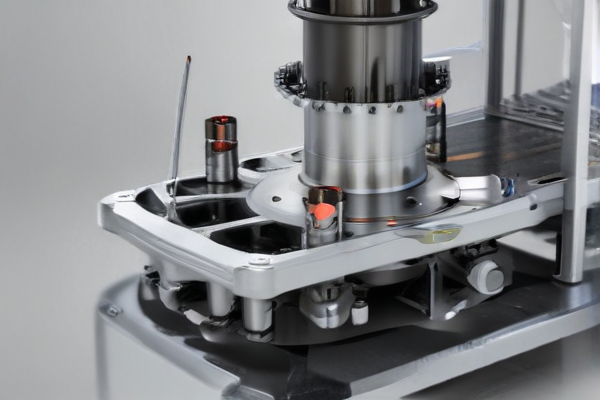

A1: SourcifyChina manufactures a range of rotary capping machines including automatic, semi-automatic, and special purpose capping machines suited for various industries such as pharmaceuticals, food and beverages, cosmetics, and chemicals.

Q2: What is the typical lead time for a rotary capping machine from SourcifyChina?

A2: The typical lead time for a rotary capping machine varies depending on customization requirements but generally ranges from 4 to 8 weeks.

Q3: Can SourcifyChina customize a rotary capping machine to fit specific production needs?

A3: Yes, SourcifyChina offers customization services to adapt the rotary capping machines according to specific production needs, cap types, and bottle sizes. Clients can provide their requirements for a tailored solution.

Q4: What quality standards do SourcifyChina’s rotary capping machines adhere to?

A4: SourcifyChina’s rotary capping machines adhere to international quality standards, including ISO and CE certifications, ensuring high quality and compliance with global regulatory requirements.

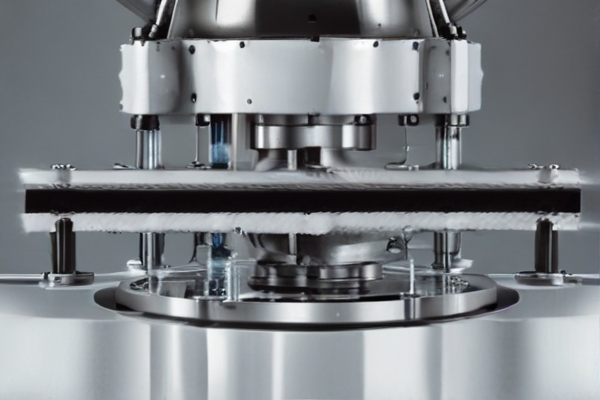

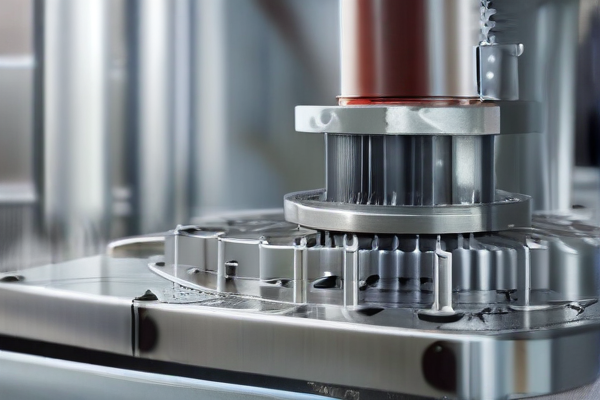

Q5: What materials are used in the construction of SourcifyChina’s rotary capping machines?

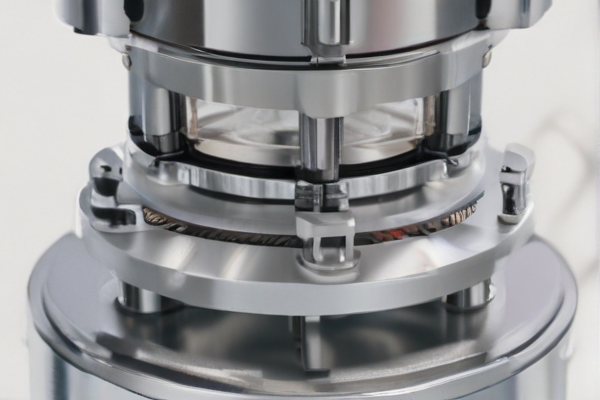

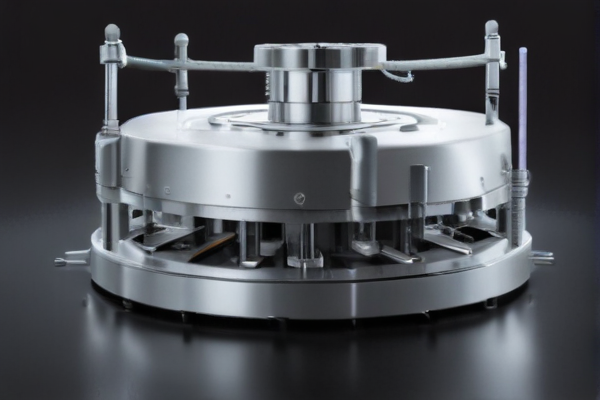

A5: SourcifyChina uses high-grade stainless steel and other quality materials to construct its rotary capping machines. This ensures durability, hygiene, and resistance to corrosion, which is crucial for industries like food and pharmaceuticals.

Q6: Does SourcifyChina provide after-sales support and training for their machines?

A6: Yes, SourcifyChina provides comprehensive after-sales support, including installation, commissioning, and training for operators. They also offer maintenance services and spare parts supply.

Q7: How can I request a quote or place an order for a rotary capping machine from SourcifyChina?

A7: You can request a quote or place an order by contacting SourcifyChina via their official website, email, or phone. Be prepared to provide details about your specific needs and production requirements for an accurate quote.

Q8: What is the warranty period for SourcifyChina’s rotary capping machines?