Sure, here’s a concise FAQ for manufacturing “sauce packing machine quality work from SourcifyChina factory”:

1. What types of sauce packing machines does SourcifyChina offer?

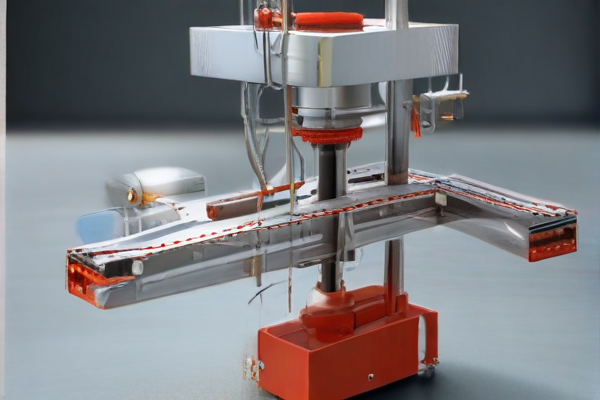

SourcifyChina manufactures a variety of sauce packing machines, including sachet packing machines, pouch packing machines, and bottle filling machines, tailored to different viscosity levels and packaging requirements.

2. How do you ensure the quality of your sauce packing machines?

We follow strict quality control protocols, including rigorous testing, calibration, and inspection processes. Our machines are built using high-grade materials and components to ensure long-lasting performance and reliability.

3. Can the machines handle various sauce viscosities?

Yes, our machines are designed to handle a wide range of viscosities, from thin, liquid sauces to thick, chunky sauces. Adjustable settings allow for precise control and customization based on the sauce type.

4. What packaging options are available?

Our machines can accommodate various packaging formats, including sachets, pouches, and bottles. Each machine is equipped with customizable settings to meet specific packaging needs.

5. How fast are the packing machines?

The speed of our sauce packing machines varies depending on the model and packaging requirements. We offer machines capable of packing anywhere from 30 to 120 packs per minute.

6. What kind of maintenance do the machines require?

Regular maintenance includes routine cleaning, lubrication, and timely replacement of wear parts. We provide detailed maintenance guidelines and support to ensure optimal machine performance.

7. Is technical support available if I encounter issues?

Yes, SourcifyChina provides comprehensive technical support, including remote assistance and on-site service, to address any operational issues or technical difficulties promptly.

8. Are custom features available for specific needs?

Absolutely, we offer customization options to meet specific requirements, such as unique packaging sizes, special filling mechanisms, and additional automation features.

9. What are the payment terms for purchasing a machine?

We offer flexible payment terms including bank transfer, credit card, and financing options. Details can be discussed during the purchase agreement.

10. How can I place an order or get a quote?

You can place an order or request a quote by contacting our sales team through our website, email, or phone. Our team will assist you in selecting the right machine and provide a detailed quotation.

These concise answers should give potential customers a clear understanding of what to expect when considering a purchase from SourcifyChina.