Sure, here are some frequently asked questions (FAQ) about sourcing a sausage packaging machine from SourcifyChina factory, with the questions in bold:

Q: What types of sausage packaging machines does SourcifyChina offer?

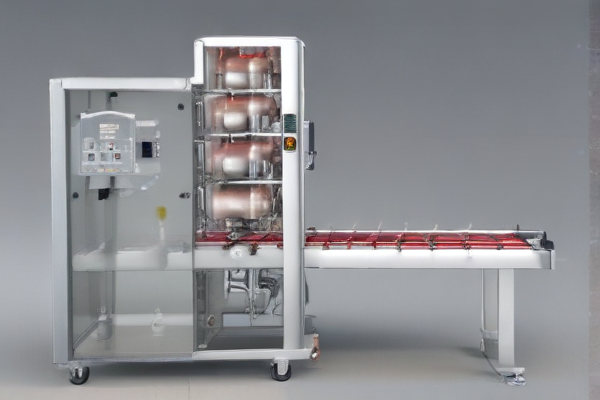

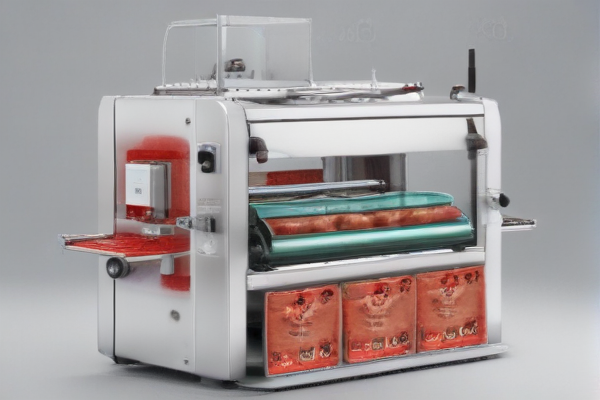

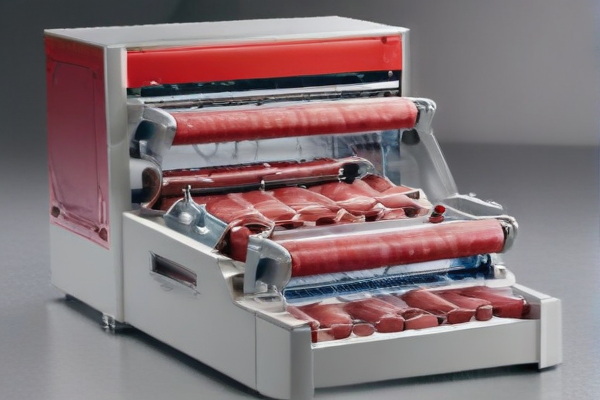

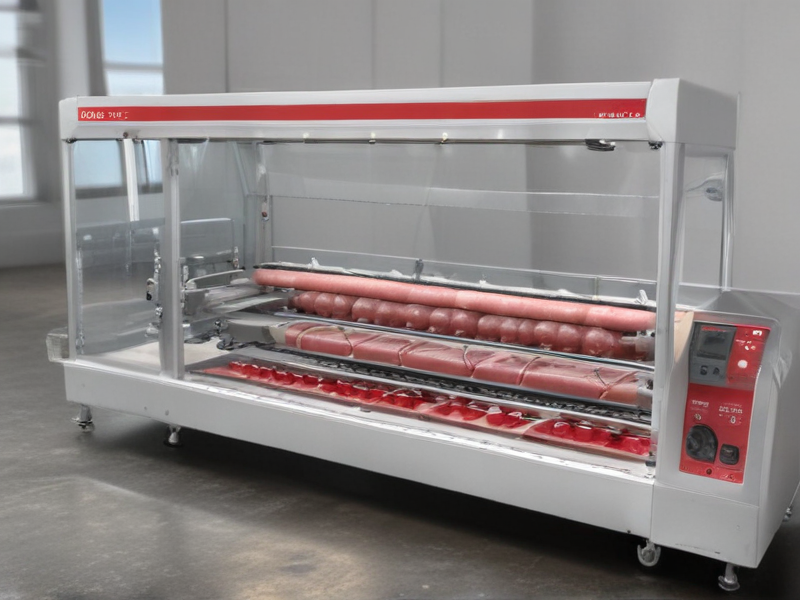

A: SourcifyChina offers a variety of sausage packaging machines including vacuum sealers, automatic form-fill-seal machines, and thermoforming machines to suit different packaging needs.

Q: How can I place an order for a sausage packaging machine?

A: You can place an order by contacting SourcifyChina directly via their website, email, or phone. They will guide you through selecting the right machine and completing the purchase process.

Q: What is the lead time for delivery?

A: The lead time varies depending on the machine’s complexity and current order volume but typically ranges from 4 to 8 weeks.

Q: Do they offer international shipping?

A: Yes, SourcifyChina provides international shipping to most countries. Shipping costs and times will depend on the destination and shipping method selected.

Q: Can they customize the sausage packaging machine to my specific needs?

A: Yes, SourcifyChina offers customization options to meet your specific packaging requirements. You can discuss your needs with their technical team.

Q: What are the payment terms?

A: SourcifyChina usually requires a deposit before production begins, with the balance payable upon completion or delivery. Specific payment terms can be discussed with their sales team.

Q: Is there a warranty for the machines?

A: SourcifyChina provides a standard warranty that covers parts and labor for a specified period, typically one year. Extended warranties may be available upon request.

Q: Do they offer technical support and training?

A: Yes, they provide technical support and can arrange for training either onsite or remotely to ensure your staff can operate the machine efficiently.

Q: What should I do if the machine encounters an issue?

A: In case of an issue, contact SourcifyChina’s customer service. They have a dedicated support team that can assist with troubleshooting and spare parts.

Q: Are there any additional costs besides the machine price?

A: Additional costs may include shipping, taxes, custom duties, installation, and training fees. Detailed pricing will be provided in the quotation.

Feel free to contact SourcifyChina for more detailed information or specific inquiries.