A screw feeding system automates the distribution of screws for assembly processes, improving efficiency and precision. Various types cater to different needs, such as pneumatic, electric, and vacuum systems, each with unique benefits.

Types of Screw Feeding Systems:

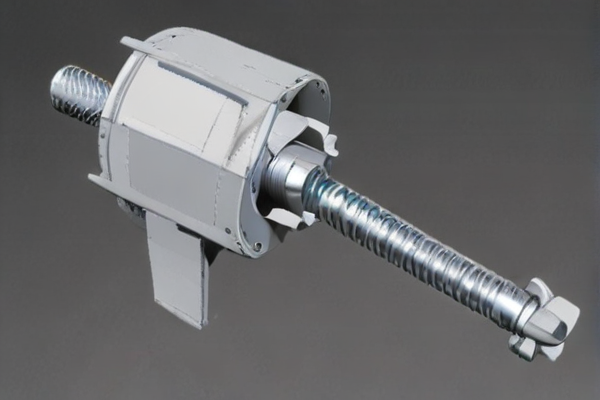

– Pneumatic Screw Feeding Systems:

– Use compressed air to feed screws

– Ideal for high-speed applications

– Low maintenance and reliable

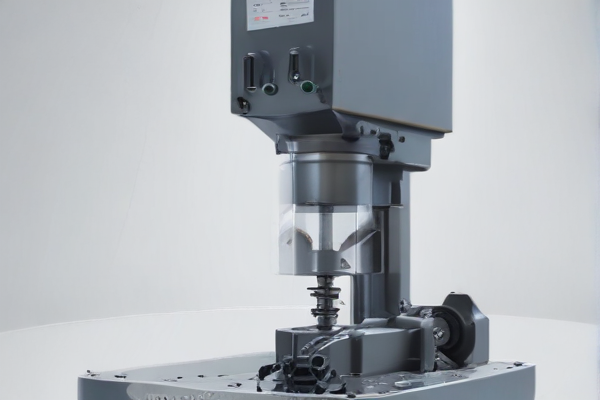

– Electric Screw Feeding Systems:

– Operate using electric motors

– Offer precise control over screw positioning and speed

– Suitable for delicate or complex assembly tasks

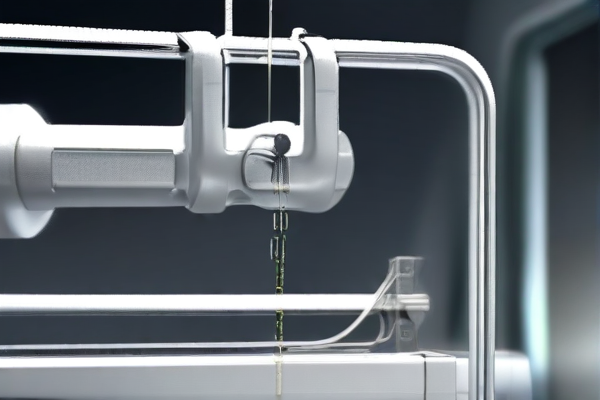

– Vacuum Screw Feeding Systems:

– Use suction to capture and position screws

– Great for handling small or light screws

– Minimize risk of screw damage

Options Available:

– Handheld Screw Feeders:

– Ergonomic design for manual use

– Increase operator efficiency and reduce fatigue

– Portable and cost-effective

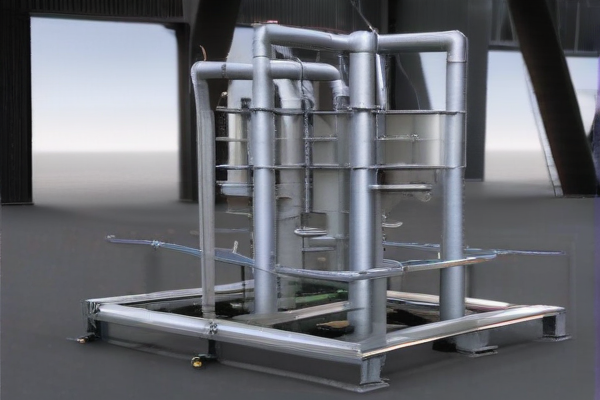

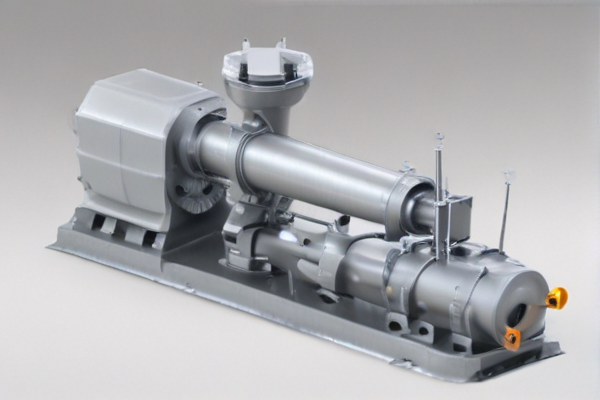

– Automatic Screw Feeders:

– Fully automated system for high volume production

– Integrate seamlessly into existing production lines

– Enhance speed and consistency in screw feeding

– Robotic Screw Feeders:

– Utilize robotic arms for automated screw placement

– High precision and repeatability

– Suitable for complex or custom assembly tasks

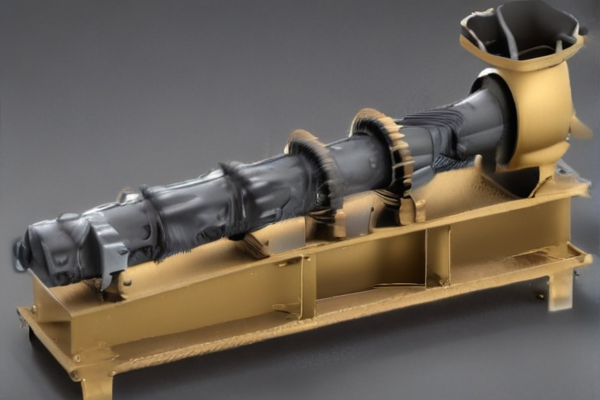

– Vibratory Bowl Feeders:

– Use vibration to orient and feed screws

– Versatile and can handle various screw sizes/shapes

– Cost-effective and reliable for continuous operation

Additional Features:

– Adjustable speed and torque settings

– Various nozzle and head configurations

– Compact designs for space-saving applications

– Smart controls with data logging and error detection

– Easy integration with other automation systems

By choosing the appropriate screw feeding system, manufacturers can enhance their productivity, ensure consistent quality, and reduce downtime.