Seafood packaging machines come in various types and options to preserve freshness and extend shelf life. They include vacuum sealers, modified atmosphere packaging (MAP) systems, and skin packaging machines.

– Vacuum Sealers: Remove air to prevent spoilage.

– Modified Atmosphere Packaging (MAP): Uses gas mixtures.

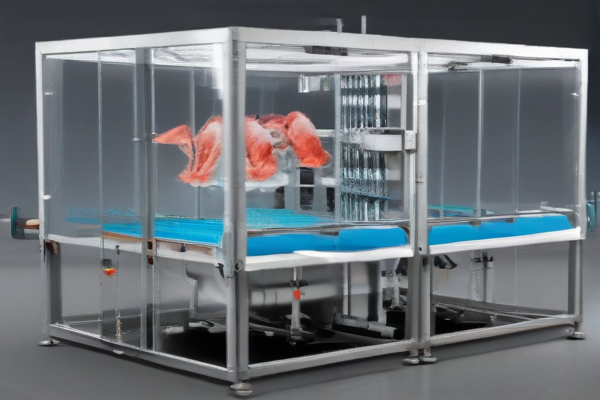

– Skin Packaging Machines: Create tight film over the product.

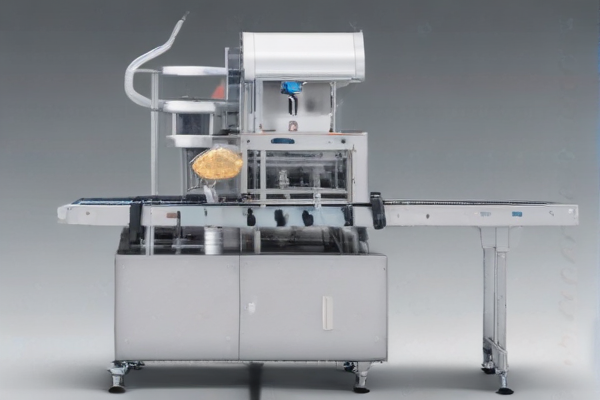

– Form-Fill-Seal Machines: Automate forming, filling, and sealing.

– Shrink Wrapping Machines: Apply heat to shrink plastic around seafood.

– Thermoforming Machines: Mold packages from plastic sheets.

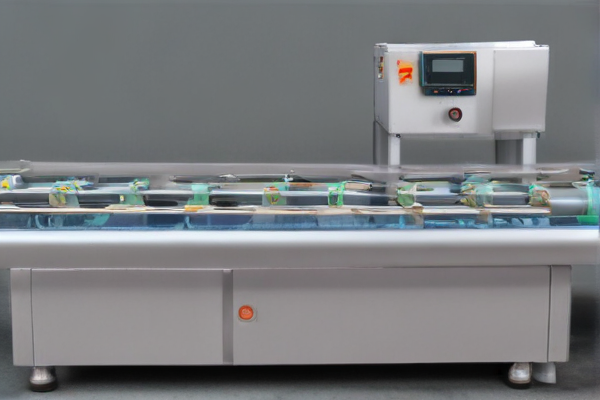

– Tray Sealers: Seal preformed trays with film lids.

– Flow Wrappers: Wrap products in clear or printed film.

– Ice Pack Solutions: Include ice during packaging to maintain cool temperatures.

– Reusable Packaging: Eco-friendly options for reducing waste.

– Cryovac Packaging: Specialized vacuum sealing for high-pressure processing.

– Canning Equipment: Seal seafood in cans for long-term storage.

– Freezing Machines: Freeze seafood before or after packaging.

– Band Sealers: Continuous sealing for bags and pouches.

– Clamshell Packaging: Hinged, clear plastic containers.

– Case Erectors: Automatically form and seal cardboard cases.

– Labeling Machines: Print and apply labels during packaging.

– Weighing and Filling Machines: Ensure accurate portioning.

– Inspection Systems: Check for quality and contaminations.

– Robotic Packaging Systems: Automated, high-speed packing solutions.

– Scale Systems: Measure product weight for consistency.

– Vacuum Tumblers: Marinate seafood with seasoning solutions.

– Gas Flush Machines: Inject inert gas to displace oxygen.

– High-Pressure Processing (HPP) Machines: Use high pressure for food safety.

– Stretch Wrapping Machines: Stretchable film for pallet protection.

– Bulk Packaging Systems: For large volumes of seafood.

– Remote Monitoring Systems: Track packaging performance.

– Heat Sealers: Simple, manual sealing solutions.

– Pouch Packaging Machines: Fill and seal preformed pouches.

These machines are crucial for ensuring seafood remains fresh, safe, and appealing to consumers while meeting regulatory requirements.