Sure, here are some frequently asked questions (FAQ) with answers about manufacturing “seal machines quality work from SourcifyChina factory”:

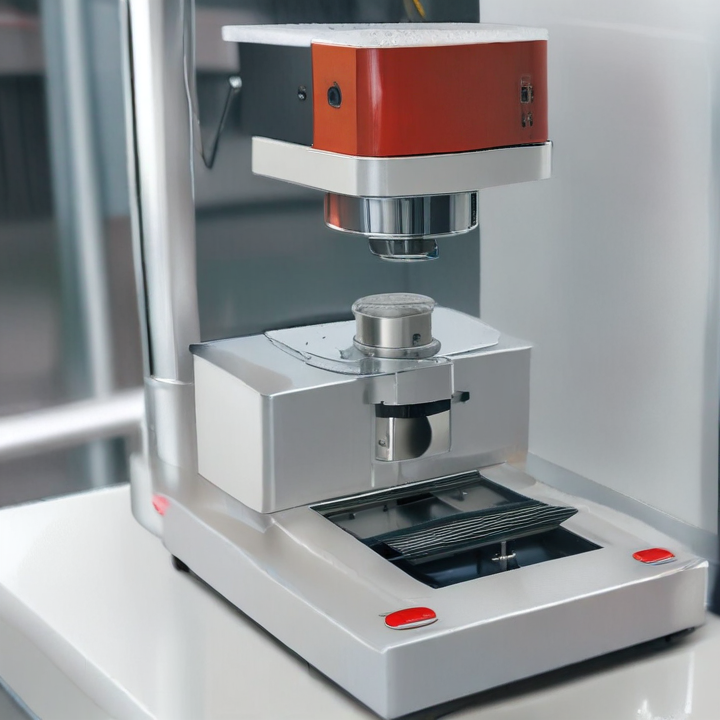

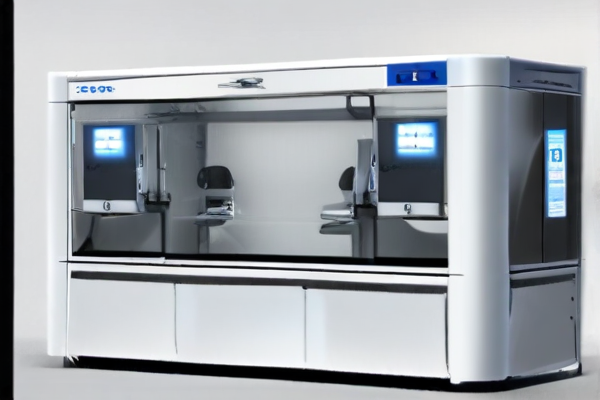

Q1: What types of seal machines does SourcifyChina factory manufacture?

A1: SourcifyChina factory specializes in producing a wide range of seal machines, including induction sealing machines, vacuum sealing machines, heat sealing machines, and ultrasonic sealing machines.

Q2: How does SourcifyChina ensure the quality of its seal machines?

A2: SourcifyChina employs rigorous quality control procedures, including ISO-certified processes, multiple testing phases, and using high-quality materials to ensure durability and efficiency.

Q3: Can I request custom specifications for my seal machines?

A3: Yes, SourcifyChina offers customization services. You can request specific sizes, capacities, and additional features tailored to your unique manufacturing needs.

Q4: What is the typical lead time for an order?

A4: The lead time varies depending on the complexity and volume of the order but generally ranges from 2 to 4 weeks. Custom orders may require additional time.

Q5: Are there any after-sale services provided?

A5: Yes, SourcifyChina provides comprehensive after-sale services, including installation support, training, and troubleshooting. Additionally, they offer long-term maintenance plans.

Q6: What are the payment terms?

A6: The payment terms typically involve a 30% deposit upfront, with the remaining 70% due before shipment. SourcifyChina accepts various payment methods, including T/T, L/C, and PayPal.

Q7: Is there a minimum order quantity (MOQ) for seal machines?

A7: The MOQ varies depending on the machine type. Generally, the MOQ is one unit for standard seal machines, but custom orders may have different requirements.

Q8: How are the seal machines shipped?

A8: Seal machines are securely packed and shipped via air or sea freight, based on customer preferences and delivery timelines.

Q9: Can I visit the SourcifyChina factory for an inspection?

A9: Yes, factory visits are welcomed. Customers can schedule an appointment to inspect the facilities and witness the manufacturing process firsthand.

Q10: How do I get a quote for seal machines from SourcifyChina?