Sure, here are some frequently asked questions (FAQs) with answers for manufacturing sealing machines from SourcifyChina factory:

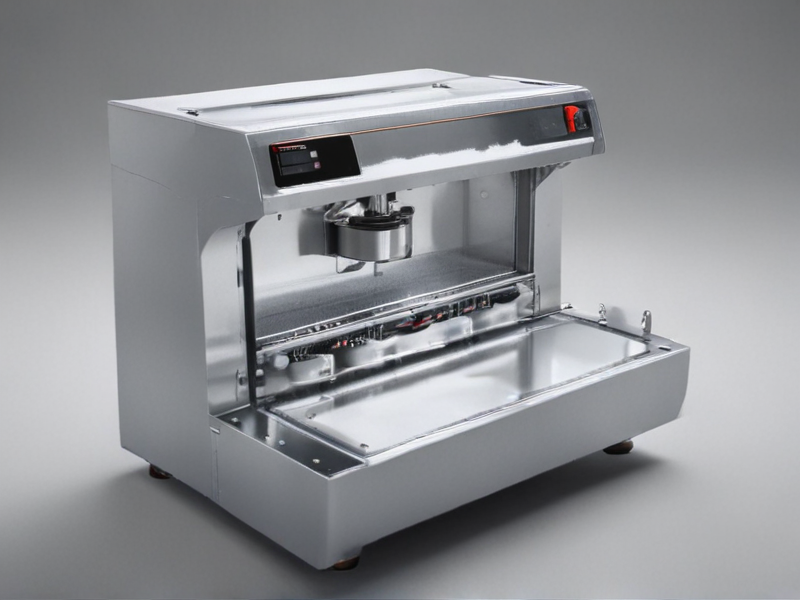

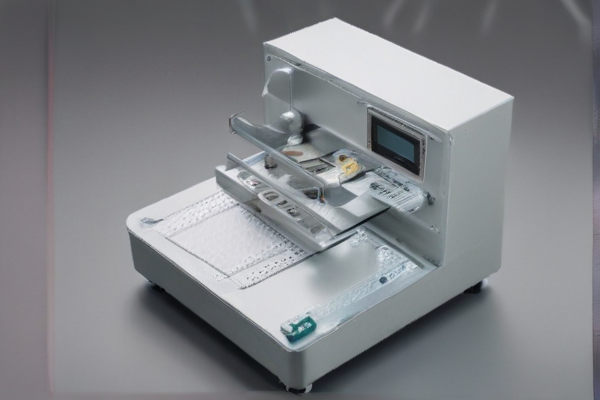

Q1: What types of sealing machines do you manufacture?

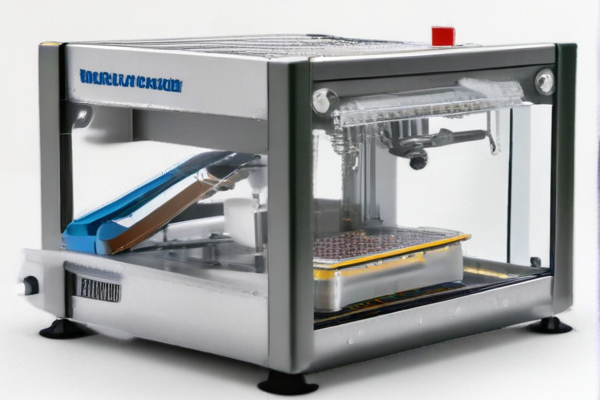

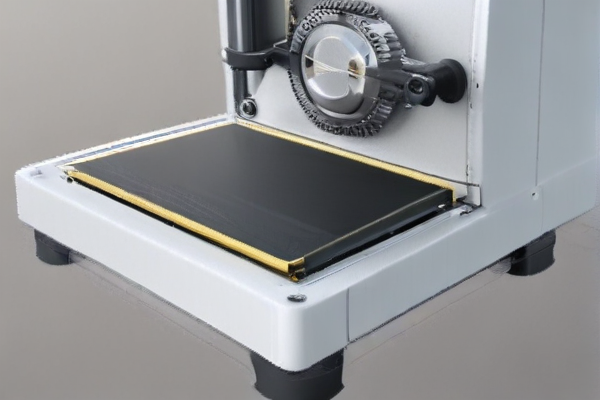

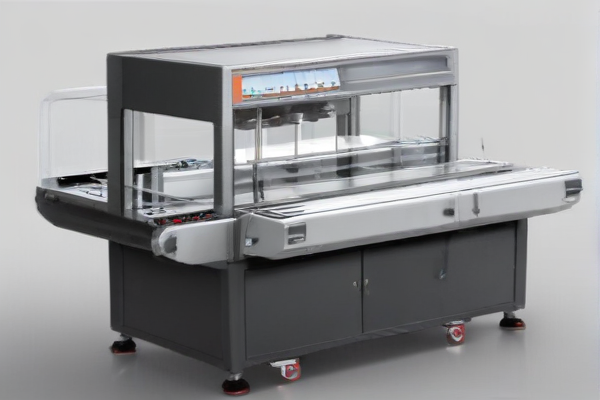

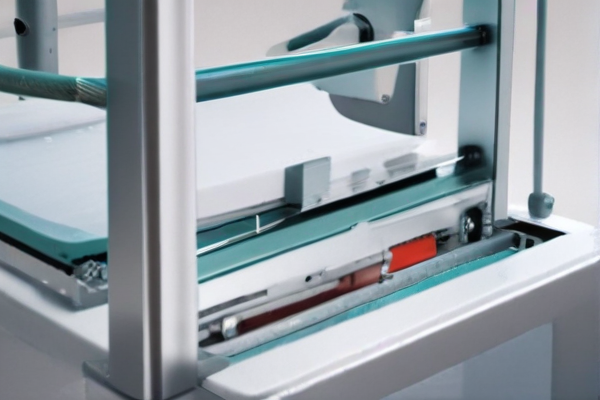

A1: SourcifyChina produces a wide range of sealing machines including heat sealers, vacuum sealers, induction sealers, and continuous band sealers, catering to various industry needs.

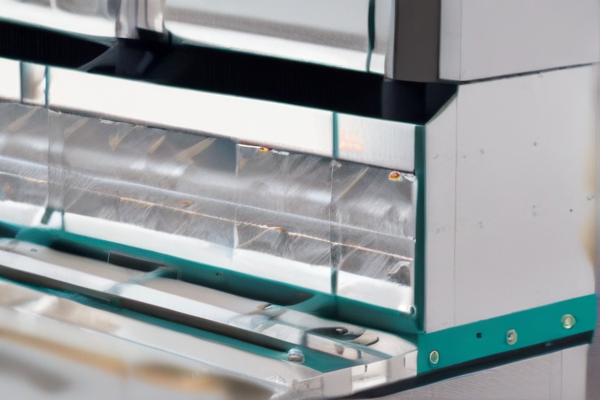

Q2: How do you ensure the quality of your sealing machines?

A2: We adhere to strict quality control processes, including raw material inspection, in-production quality checks, and final testing before shipment. All machines comply with international standards like ISO and CE.

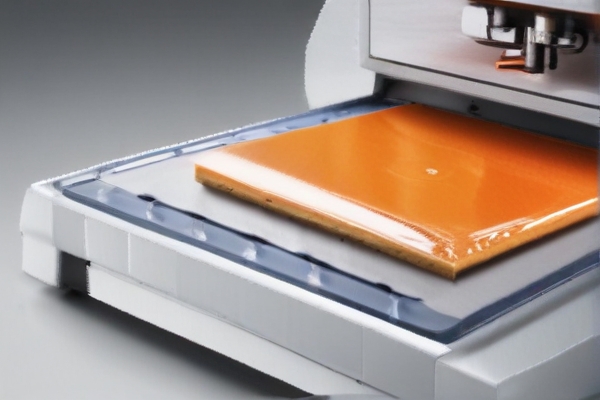

Q3: Can I customize my sealing machine?

A3: Yes, we offer customizable options to meet specific requirements. You can modify dimensions, functionalities, and other specifications based on your needs.

Q4: What is the lead time for manufacturing and delivery?

A4: The lead time varies depending on the model and customization. Typically, it takes 2-4 weeks for manufacturing and an additional 1-2 weeks for shipping.

Q5: Do you offer after-sales service?

A5: Yes, we provide comprehensive after-sales services including installation support, troubleshooting, and maintenance. Our customer service team is available 24/7 to assist you.

Q6: How can I place an order?

A6: You can place an order by contacting our sales team via email or phone. They will guide you through the process, provide quotes, and assist with any queries.

Q7: What payment methods do you accept?

A7: We accept various payment methods including bank transfers, PayPal, and letters of credit. Details will be provided during the ordering process.

Q8: Is there a warranty on your sealing machines?

A8: Yes, all our sealing machines come with a one-year warranty covering manufacturing defects. Extended warranties are also available upon request.

Q9: Can I visit your factory for an inspection?

A9: Absolutely, we welcome factory visits. Please schedule your visit in advance so we can arrange a comprehensive tour and meet all your requirements.

Q10: Do you provide training for operating the sealing machine?

A10: Yes, we offer on-site and remote training sessions to ensure your staff can operate the machines efficiently.