Seasoning packaging machines come in various types, including vertical form fill seal (VFFS) machines, horizontal flow wrappers, and sachet packing machines, each designed for specific packaging needs, ensuring efficiency and freshness.

– Vertical Form Fill Seal (VFFS) Machines

– Suitable for high-speed packaging

– Compatible with various bag types (pillow, gusseted)

– Ideal for granular or powdered seasonings

– Horizontal Flow Wrappers

– Wraps seasonings in a continuous motion

– Best for individual packs or small sachets

– Provides airtight seals to preserve freshness

– Sachet Packing Machines

– Specializes in small, single-use packets

– Perfect for sample sizes or portion control

– Customizable for different sachet shapes and sizes

– Multi-Lane Stick Pack Machines

– Allows for simultaneous packing in multiple lanes

– Efficient for high-volume production

– Often used for stick-shaped packets

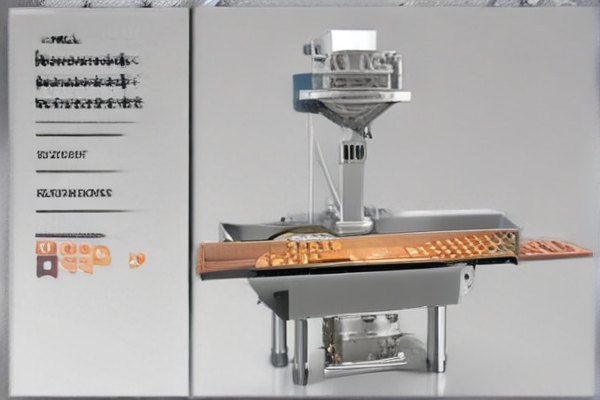

– Automatic Weighing and Packaging Systems

– Weighing and dispensing integrated into one system

– Ensures precise quantity for each package

– Reduces human error and increases consistency

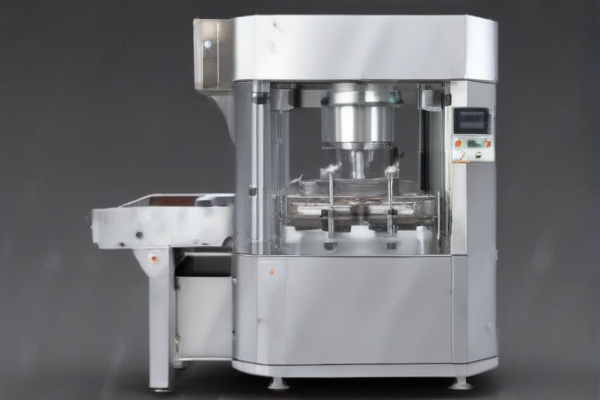

– Rotary Packing Machines

– Operates on a rotary system for efficient packaging

– Can handle different bag sizes and types

– Flexible for various packaging formats

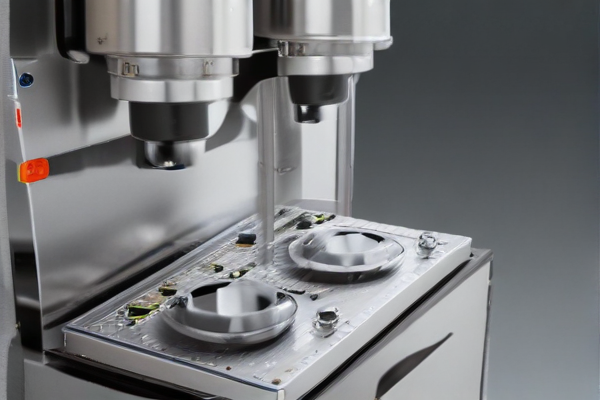

– Auger Fillers

– Uses an auger to fill powders into bags or containers

– Ideal for precise filling of powdered seasonings

– Can be integrated with VFFS or other systems

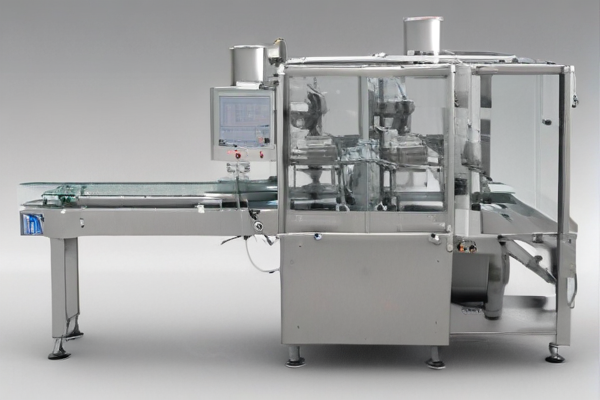

– Pre-Made Pouch Packaging Machines

– Uses pre-made pouches for faster setup

– Suitable for premium or customized packaging options

– Often includes resealable features for convenience

– Vacuum Packing Machines

– Removes air to extend shelf life

– Ideal for bulk packaging of seasonings

– Ensures long-term preservation and freshness

Choosing the right seasoning packaging machine depends on factors like production volume, packaging type, and specific seasoning properties.