Sure! Here’s a list of frequently asked questions (FAQ) with answers for sourcing a shrink sleeve labeling machine from SourcifyChina factory:

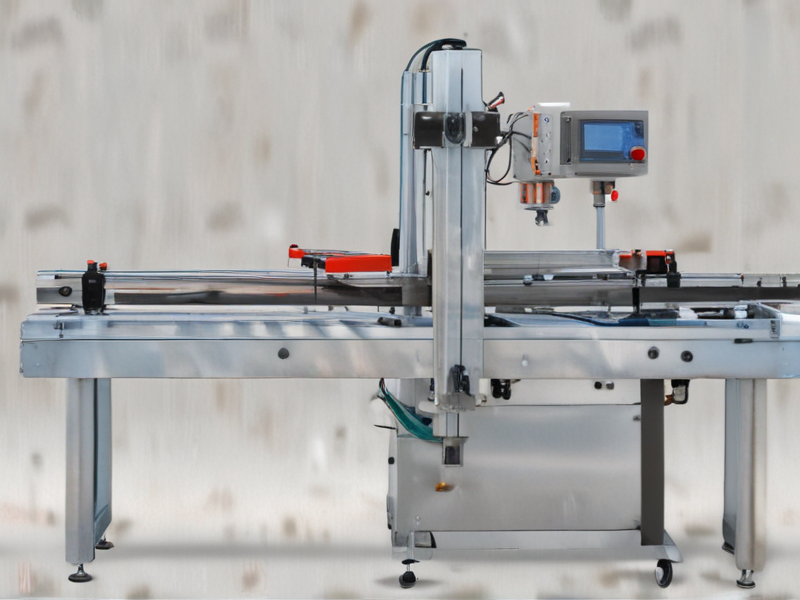

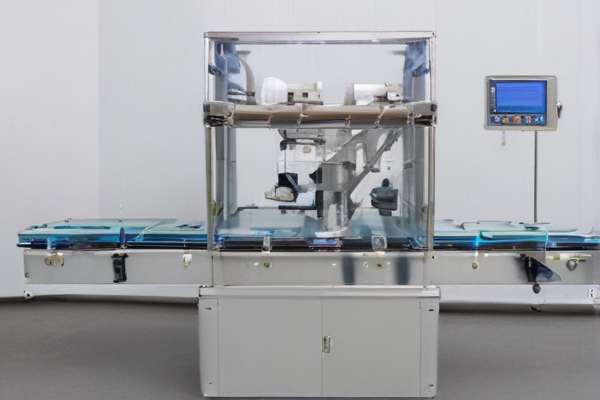

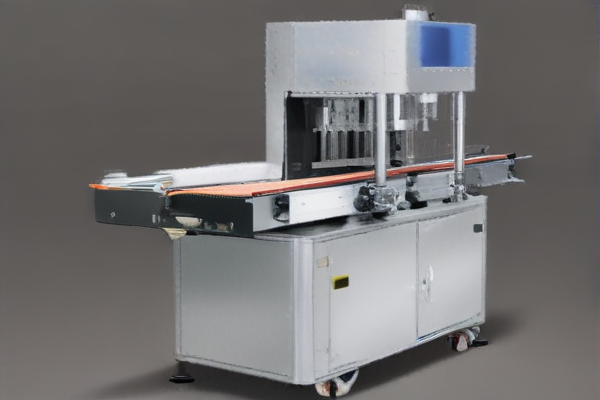

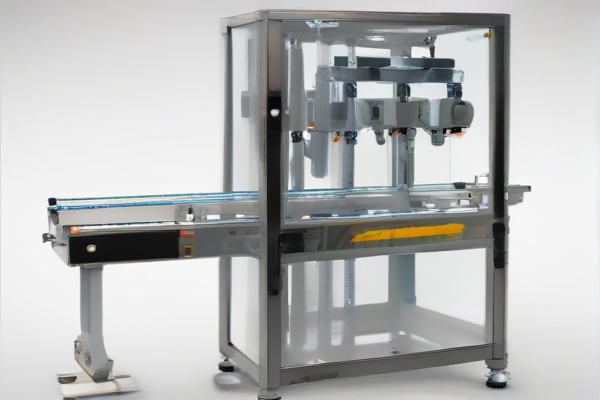

1. What is a shrink sleeve labeling machine?

A shrink sleeve labeling machine applies shrink sleeve labels to containers. The labels are made from a heat-sensitive material that shrinks to fit the container’s shape when exposed to heat.

2. Why choose SourcifyChina for sourcing shrink sleeve labeling machines?

SourcifyChina offers high-quality, cost-effective machines with robust customer support and customization options. They ensure compliance with international standards and provide comprehensive after-sales service.

3. How can I place an order with SourcifyChina?

To place an order, visit the SourcifyChina website, browse their product catalog, and contact their sales team via email or phone to discuss your requirements.

4. Can the shrink sleeve labeling machine be customized?

Yes, SourcifyChina provides customization options to tailor the machine to your specific needs, including adjustments for different container shapes and sizes.

5. What are the lead times for delivery?

Lead times vary based on customization and order size, typically ranging from 4 to 8 weeks. Confirm the exact timeline with your SourcifyChina representative.

6. What are the payment terms?

SourcifyChina generally accepts payment via bank transfer, with terms often including a deposit before production and the balance before shipment. Specific terms can be negotiated.

7. Do the machines come with a warranty?

Yes, SourcifyChina provides a standard one-year warranty on their shrink sleeve labeling machines, covering parts and labor. Additional warranty options may be available.

8. How is the machine shipped and installed?

SourcifyChina arranges shipping via sea or air freight. Installation services, including instructions and on-site support, can also be arranged if required.

9. What type of after-sales support is available?

SourcifyChina offers comprehensive after-sales support, including technical assistance, spare parts availability, and troubleshooting services.

10. How can I ensure the machine meets my quality standards?

SourcifyChina adheres to strict quality control measures and provides detailed specifications and documentation. You can request pre-shipment inspections or third-party audits for added assurance.

This concise FAQ covers essential aspects of sourcing a shrink sleeve labeling machine from SourcifyChina factory, aiming to address common questions efficiently.