Sure, here is a concise FAQ for sourcing a side labeling machine from SourcifyChina factory:

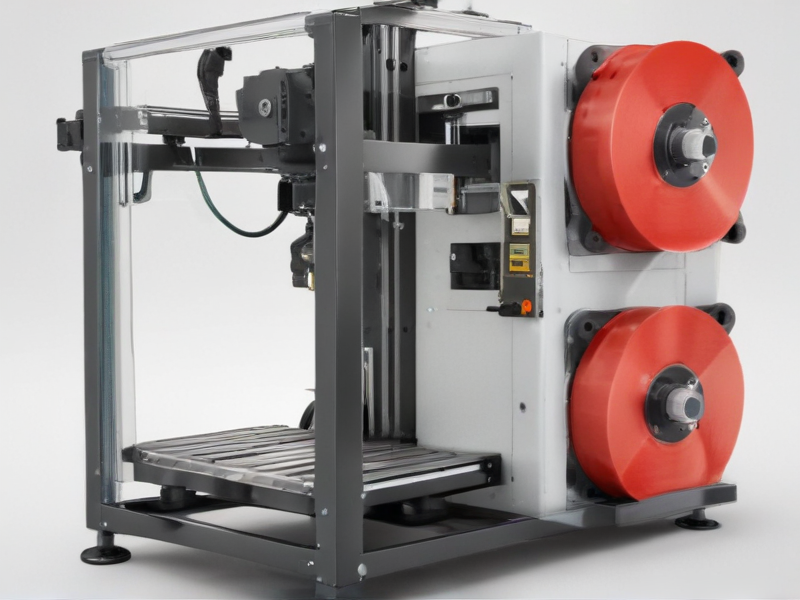

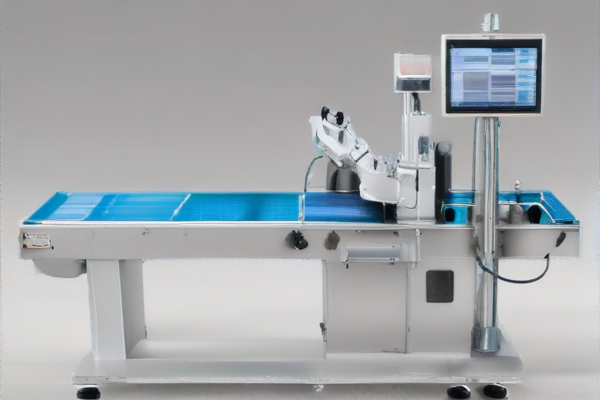

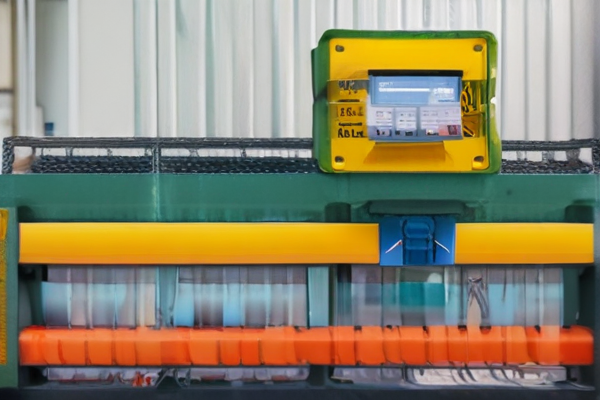

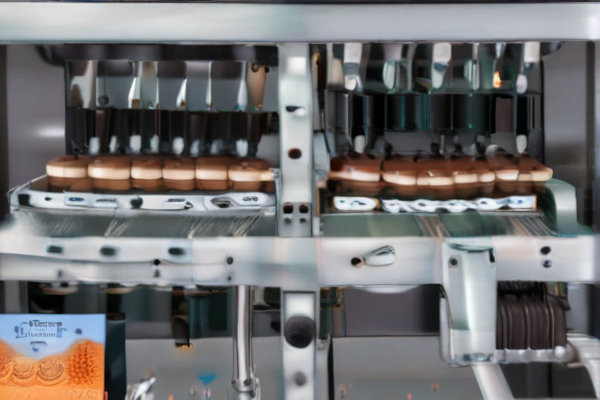

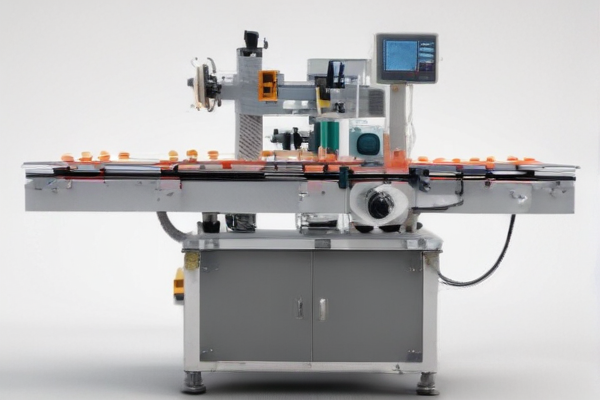

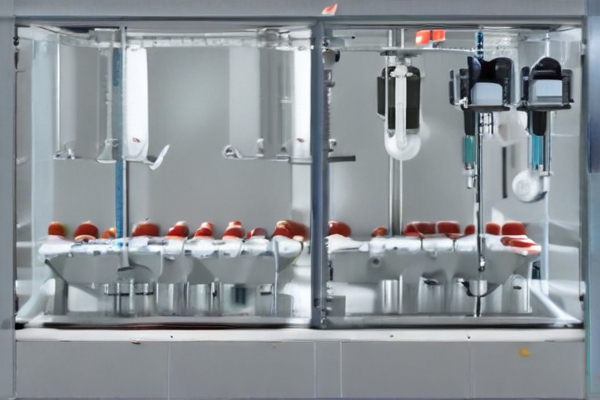

1. What types of side labeling machines does SourcifyChina offer?

SourcifyChina offers a variety of side labeling machines including automatic, semi-automatic, and manual machines. Each type caters to different production scales and specific requirements.

2. What are the lead times for delivery?

Typically, the lead time for delivery ranges from 4 to 6 weeks, depending on the machine’s model, customizations, and current order volumes.

3. Do you provide customization options?

Yes, SourcifyChina offers customization options such as unique label sizes, machine color, and integration with existing production lines to meet specific client needs.

4. Is there a minimum order quantity (MOQ)?

Generally, there is no strict MOQ for side labeling machines. However, bulk orders often come with discounts and additional perks.

5. What kind of after-sales support is available?

SourcifyChina provides comprehensive after-sales support including installation guidance, training, maintenance services, and spare parts supply.

6. How do you ensure the quality of the machines?

The machines undergo stringent quality control measures and are tested for performance and durability. They also comply with international standards, ensuring high-quality deliveries.

7. What are the payment terms?

Standard payment terms include a 30% deposit upon order confirmation and the remaining 70% upon shipment. Other terms can be negotiated as per mutual agreement.

8. Can I visit the factory for an inspection before purchasing?

Yes, potential buyers are welcome to visit the factory. An appointment can be scheduled to facilitate the visit and provide a comprehensive tour.

9. Is technical support available for troubleshooting?

Absolutely. SourcifyChina offers technical support via phone, email, and video conferencing to assist with any troubleshooting issues.

10. What shipping options are available?

The factory provides multiple shipping options including sea, air, and land transport, depending on the destination and client preference.

This FAQ should help answer common questions regarding sourcing a side labeling machine from SourcifyChina factory effectively.