Sure, here’s a sample FAQ for manufacturing “snacks packing machine quality work from SourcifyChina factory”:

1. What types of snack packing machines does SourcifyChina offer?

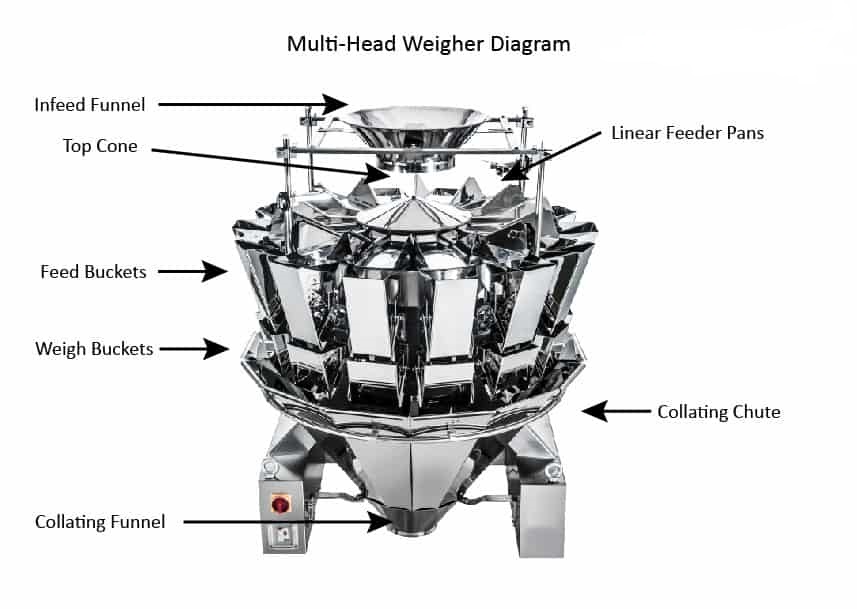

SourcifyChina offers various snack packing machines including vertical form fill seal machines, horizontal flow wrap machines, and multi-head weigher packing machines designed to handle different types of snacks such as chips, nuts, biscuits, and more.

2. What materials are used in the construction of these machines?

Our snack packing machines are primarily constructed from high-quality stainless steel to ensure durability, hygiene, and compliance with food safety standards.

3. Can these machines handle different packaging sizes?

Yes, our machines are versatile and can be easily adjusted to accommodate different packaging sizes and product types, making them ideal for varied production needs.

4. How does SourcifyChina ensure the quality of its machines?

We adhere to strict quality control measures, including thorough testing and inspections at multiple stages of manufacturing. Our machines are built to meet international standards and certifications.

5. What is the average lead time for a machine order?

The average lead time for a standard machine is around 6-8 weeks. Custom orders may take longer, depending on specific requirements and customizations.

6. Do you provide installation and training services?

Yes, we offer comprehensive installation and training services to ensure your team can operate the machines efficiently. Our technical experts are also available for ongoing support as needed.

7. What kind of warranty does SourcifyChina provide?

We offer a one-year warranty on our snack packing machines, covering parts and labor. Extended warranty options are also available upon request.

8. Can the machines integrate with existing production lines?

Yes, our machines are designed for easy integration with existing production lines, providing seamless operations and enhanced productivity.

9. Do you offer customization options for specific needs?

Absolutely, we can customize our machines according to your specific packaging needs, including adjustments in speed, size, and additional features.

10. How do I place an order or request a quote?

You can contact us directly via our website, email, or phone. Provide your specific requirements, and our sales team will guide you through the process and provide a detailed quote.

This concise and informative FAQ should help clarify common questions about SourcifyChina’s snack packing machines.