Sure, here’s a FAQ list for manufacturing spout pouch packaging machines with quality assurance from the SourcifyChina factory:

Q: What types of spout pouch packaging machines does SourcifyChina manufacture?

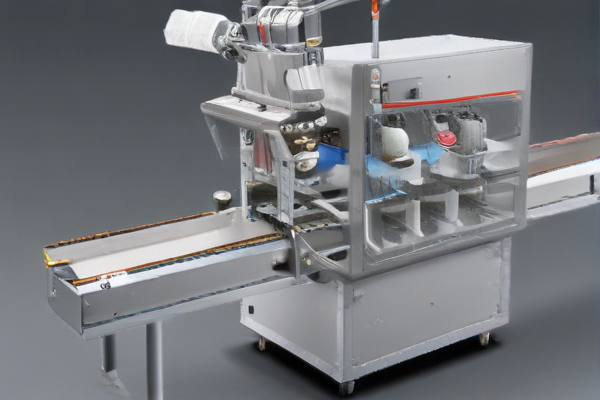

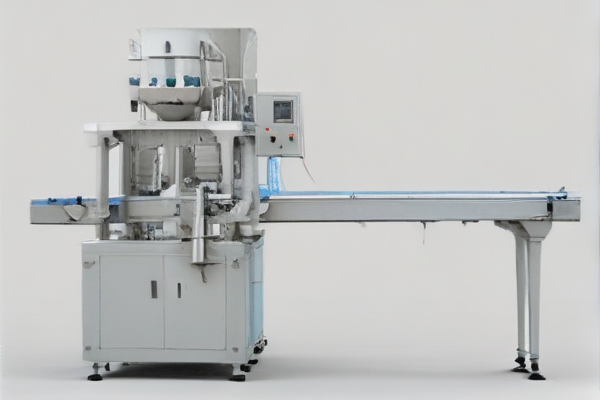

A: SourcifyChina manufactures a variety of spout pouch packaging machines including automatic filling and capping machines, stand-up pouch filling machines, and multi-function packaging systems to accommodate different packaging needs.

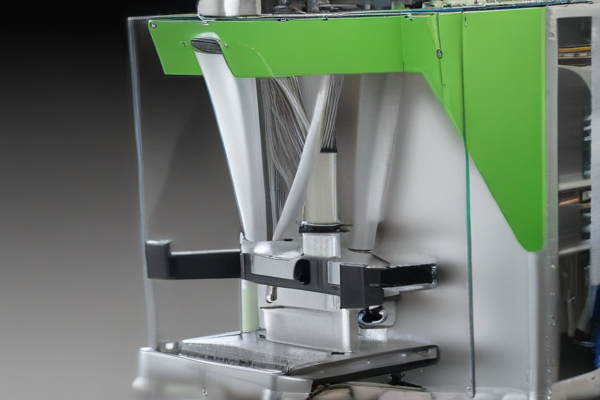

Q: What materials are used in the construction of these machines?

A: Our machines are constructed using high-quality stainless steel and industrial-grade components to ensure durability, hygiene, and optimal performance.

Q: Can these machines handle different sizes and types of pouches?

A: Yes, SourcifyChina’s spout pouch packaging machines are versatile and can be customized to handle different sizes and types of pouches, including stand-up pouches, flat pouches, and gusseted pouches.

Q: How do you ensure the quality of the spout pouch packaging machines?

A: Quality assurance is our top priority. We implement rigorous testing and quality control measures throughout the manufacturing process, including functionality tests, durability checks, and compliance with international standards.

Q: What kind of after-sales support does SourcifyChina provide?

A: We offer comprehensive after-sales support including installation assistance, user training, maintenance services, and prompt technical support to ensure your machines operate smoothly.

Q: Are the machines energy-efficient?

A: Yes, our spout pouch packaging machines are designed to be energy-efficient, helping you reduce operational costs while maintaining high productivity.

Q: How long is the warranty period for these machines?

A: SourcifyChina provides a standard one-year warranty on all spout pouch packaging machines. Extended warranty options are also available upon request.

Q: Can the machines be integrated into an existing production line?

A: Absolutely, our machines are designed to be easily integrated into existing production lines to enhance operational efficiency and productivity.

Q: How long does it take to deliver a machine from the time of order?

A: Delivery timelines vary based on the customization requirements and the current production schedule. Typically, it takes 4 to 8 weeks from the time of order.

Q: Do you offer customization options for the machines?

A: Yes, SourcifyChina offers extensive customization options to meet your specific packaging needs, including modifications to machine design, functionality, and automated features.