Sure, here’s a list of frequently asked questions (FAQ) along with their answers for manufacturing “stretch film wrapping machine quality work from SourcifyChina factory.”

1. What makes SourcifyChina’s stretch film wrapping machines high quality?

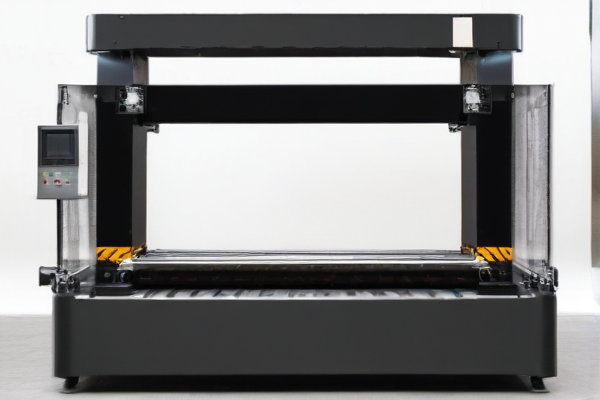

SourcifyChina uses advanced technology, high-quality materials, and rigorous quality control processes to ensure their machines are reliable, durable, and efficient.

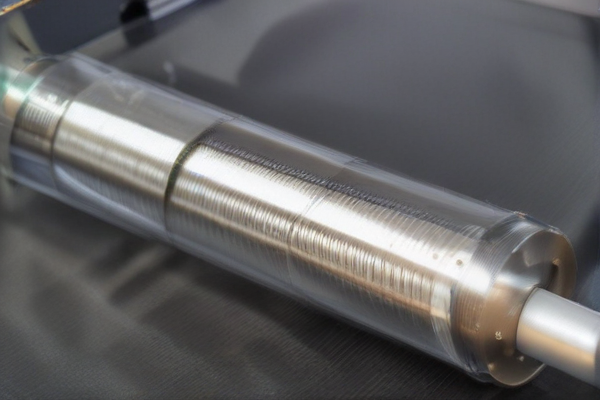

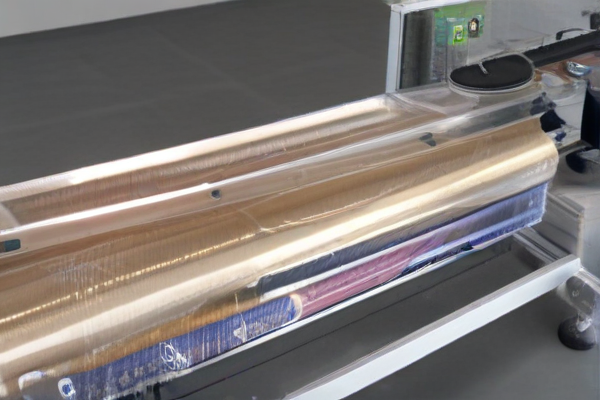

2. How does SourcifyChina ensure the durability of their machines?

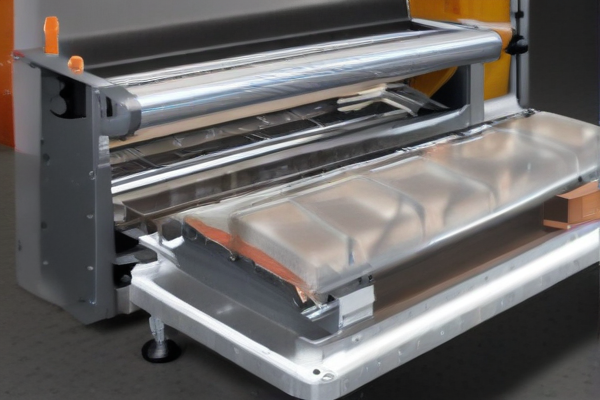

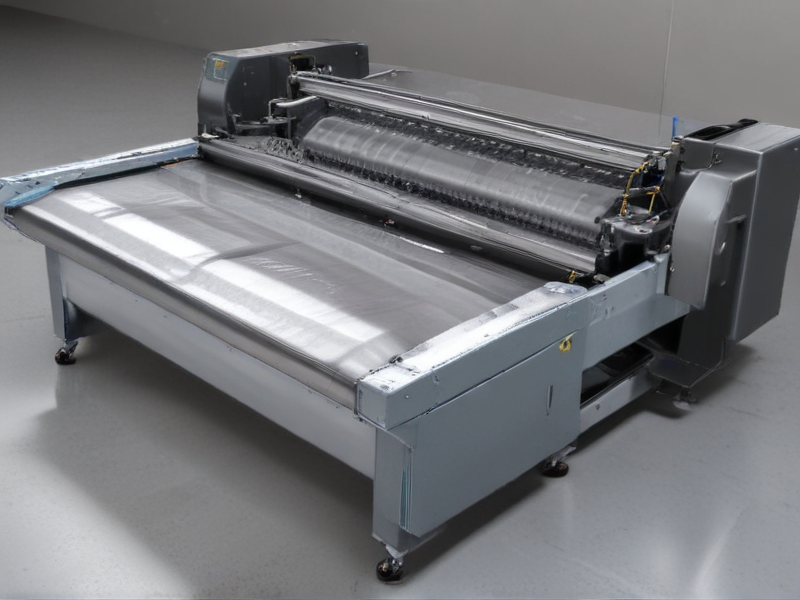

The factory employs robust design principles and uses premium-grade materials such as stainless steel and high-strength plastics. Additionally, all machines undergo extensive testing to guarantee their longevity.

3. Can SourcifyChina customize a stretch film wrapping machine to my specific needs?

Yes, SourcifyChina offers customization services to tailor the specifications of their machines according to the specific requirements of your operation.

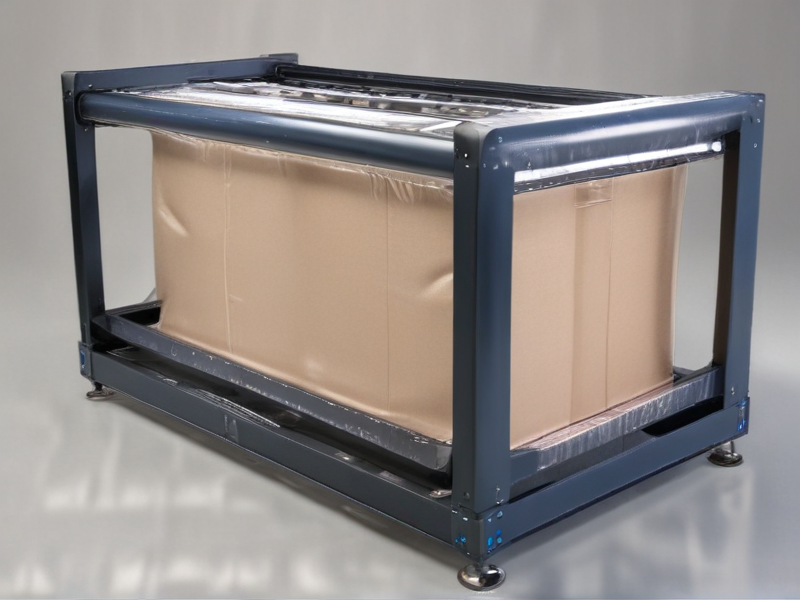

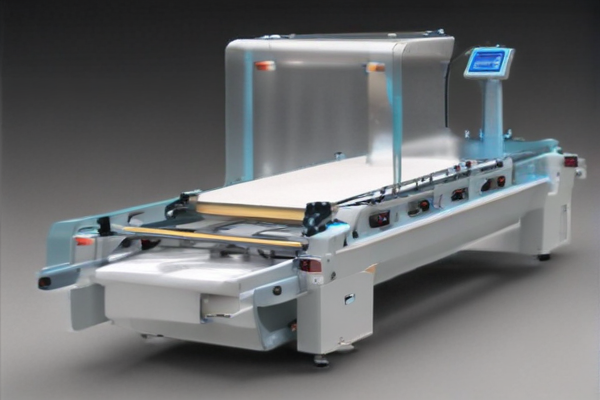

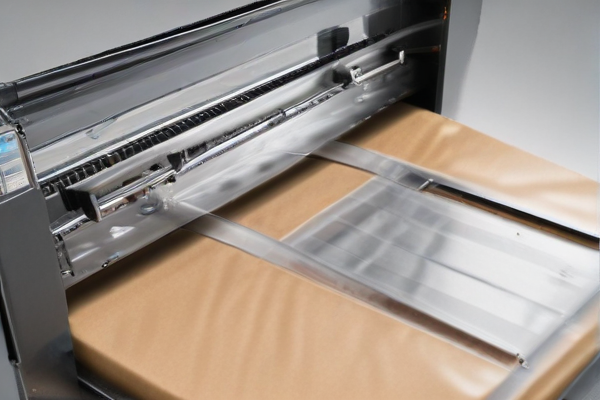

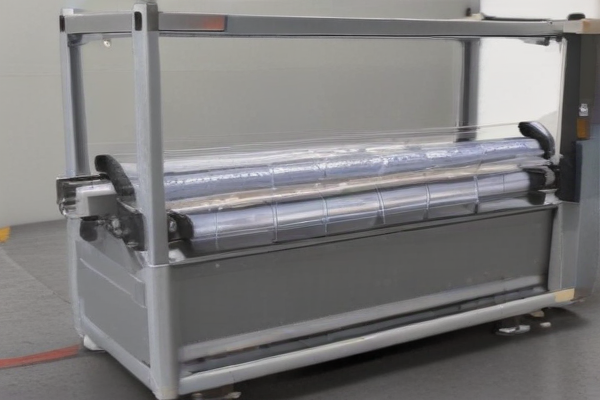

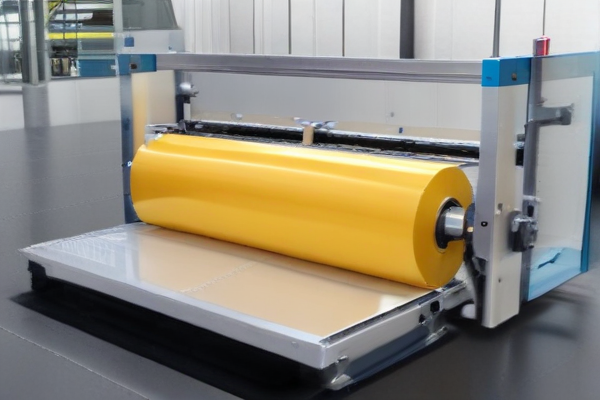

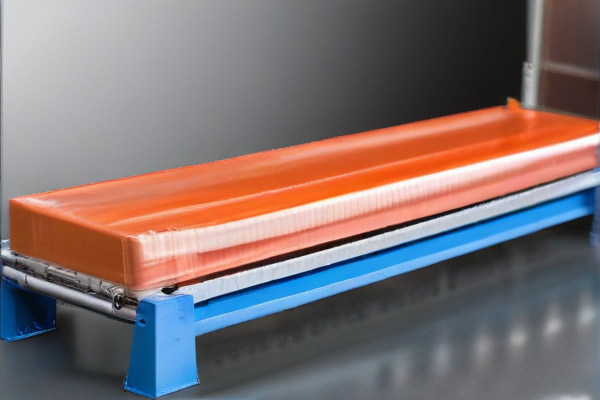

4. What types of stretch film wrapping machines does SourcifyChina manufacture?

SourcifyChina manufactures various types including automatic and semi-automatic stretch film wrapping machines, pallet wrapping machines, and rotary arm stretch wrap machines.

5. How is the after-sales support for these machines?

SourcifyChina provides robust after-sales support, including training, maintenance services, and a comprehensive warranty to ensure the machines continue to perform optimally.

6. Are the machines energy-efficient?

Yes, SourcifyChina designs its machines to be energy-efficient, using modern motors and control systems to maximize productivity while minimizing power consumption.

7. How long does it take to receive a machine after placing an order?

Delivery times vary depending on the machine and customization needs, but generally, it takes about 4-8 weeks from order confirmation to delivery.

8. Do the machines come with installation and operation manuals?

Yes, every machine comes with detailed installation and operation manuals to facilitate easy setup and use.

9. Can I request a demonstration before purchasing a machine?

Yes, SourcifyChina offers demonstrations to showcase the capabilities and quality of their machines. You can schedule a demo by contacting their sales team.

10. What certifications do SourcifyChina’s stretch film wrapping machines have?

The machines are certified under globally recognized standards such as ISO and CE, ensuring they meet the highest quality and safety benchmarks.

This concise FAQ should help address common inquiries regarding SourcifyChina’s stretch film wrapping machines.