FAQ for Syringe Filling Machine Quality Work from SourcifyChina Factory

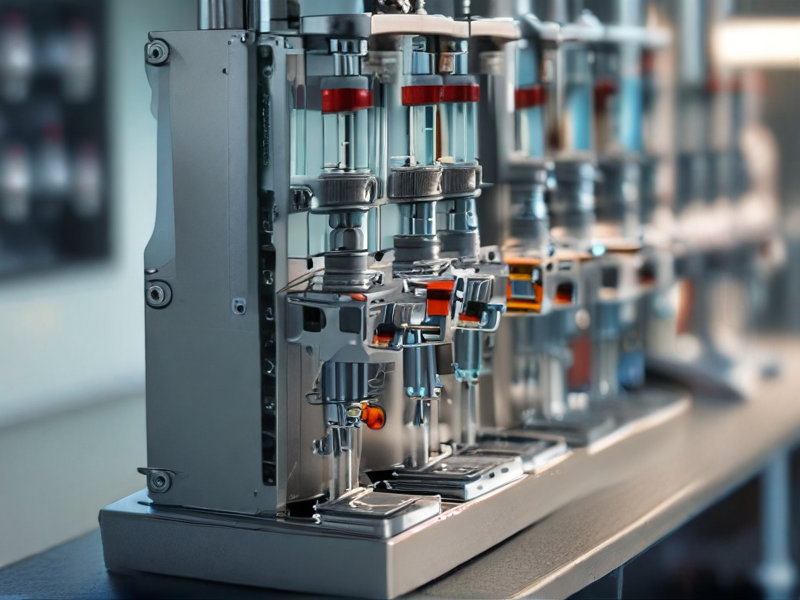

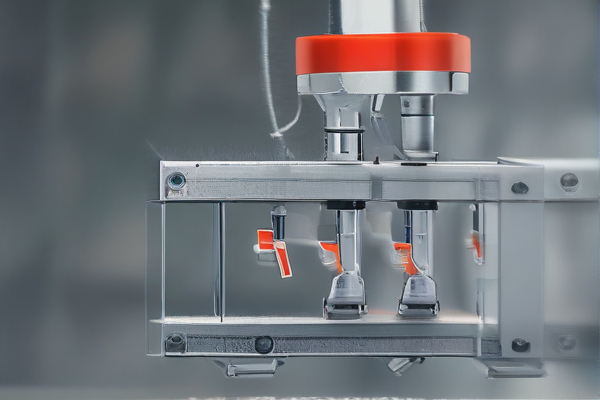

Q1: What materials are used in the construction of the syringe filling machine?

A1: SourcifyChina uses high-quality stainless steel and corrosion-resistant materials to ensure durability and hygiene. All components meet international quality standards.

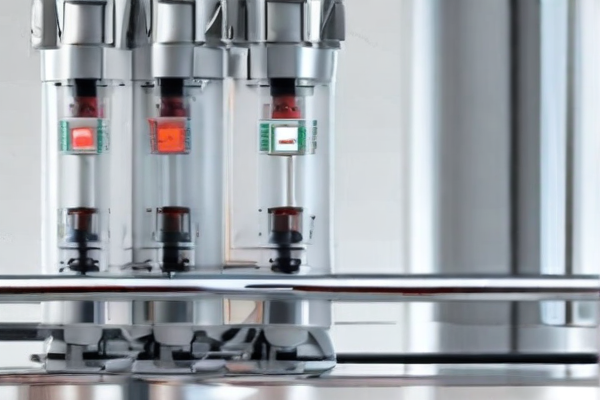

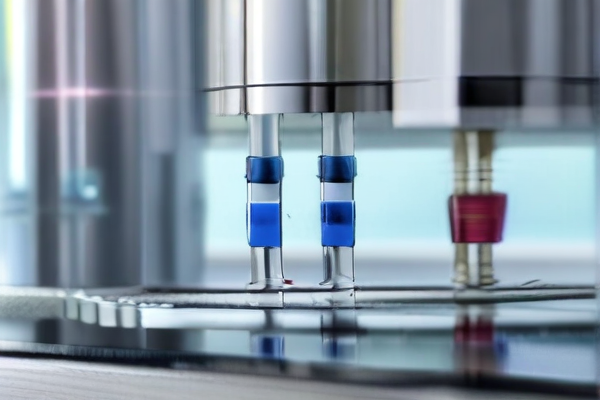

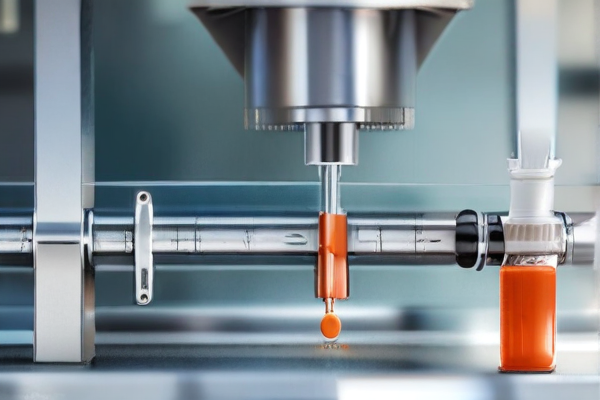

Q2: How accurate is the filling process?

A2: The syringe filling machines from SourcifyChina feature high-precision filling technology, ensuring an accuracy rate of ±0.5%, thereby reducing wastage and ensuring consistency.

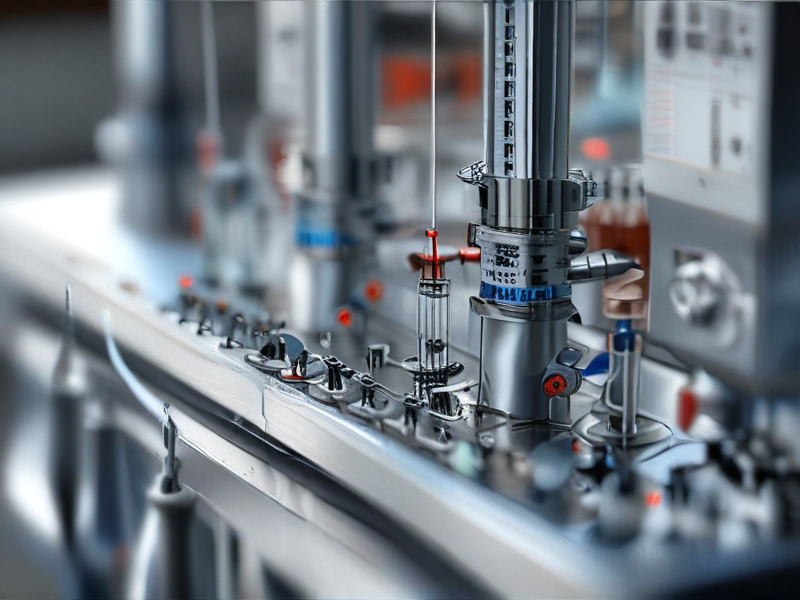

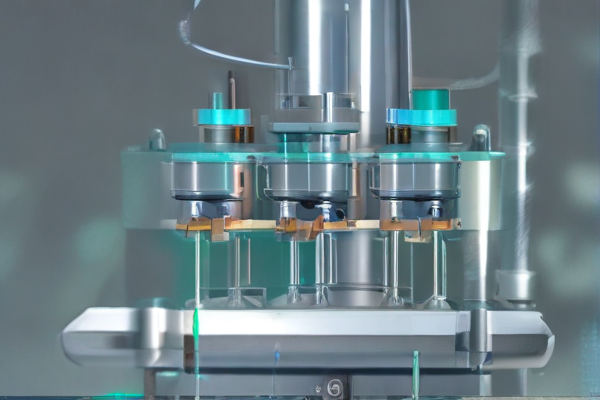

Q3: What is the capacity of the syringe filling machine?

A3: The machine is designed to handle various production scales, ranging from small to large capacities. Specific models can fill from 5,000 to 20,000 syringes per hour.

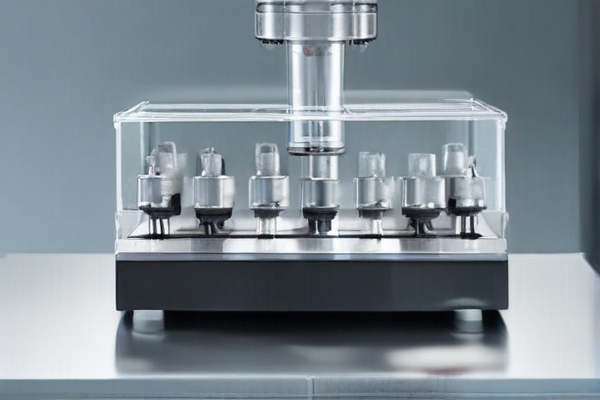

Q4: Is the machine easy to clean and maintain?

A4: Yes, the machine is designed for easy cleaning and maintenance. It includes CIP (Clean-In-Place) systems and modular components that are easy to disassemble and reassemble.

Q5: Does SourcifyChina offer after-sales service and technical support?

A5: Absolutely. SourcifyChina provides comprehensive after-sales service, including installation, training, and technical support to ensure smooth operation and minimal downtime.

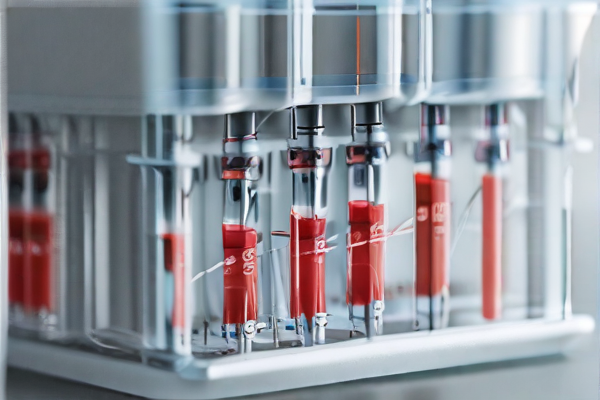

Q6: What types of syringes can the machine handle?

A6: The machine is versatile and can fill various types and sizes of syringes, including luer-lock, luer-slip, and safety syringes, adapting to the specific needs of different medical applications.

Q7: How energy-efficient is the syringe filling machine?

A7: SourcifyChina’s syringe filling machines are designed to be energy-efficient, employing advanced technology to minimize power consumption while maximizing productivity.

Q8: Can the machine integrate with existing production lines?

A8: Yes, the machines are designed with flexibility in mind and can be easily integrated into existing production lines, enhancing efficiency and reducing the need for additional infrastructure.

Q9: What certifications do the machines have?

A9: SourcifyChina’s syringe filling machines are certified by international standards such as ISO, CE, and GMP, ensuring high quality and compliance with global industry standards.

Q10: How long is the warranty for the syringe filling machine?

A10: The machines come with a standard one-year warranty, which covers parts and labor. Extended warranty options are also available for added peace of mind.