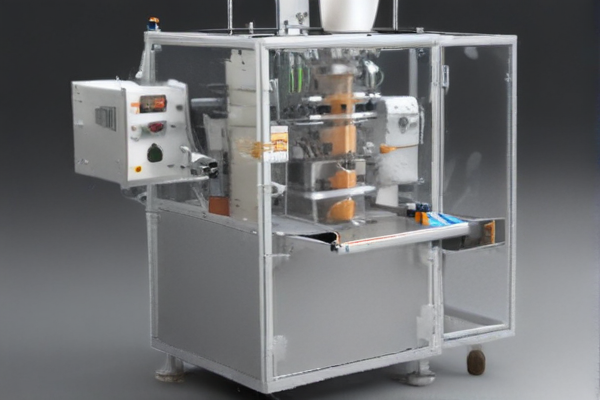

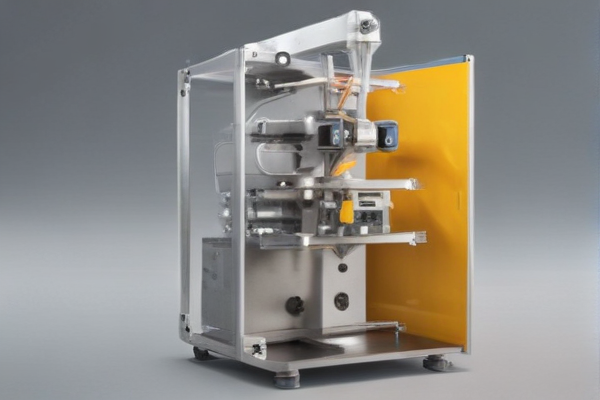

Q1: What are the key features of your tea bag packing machines?

A1: Our tea bag packing machines from SourcifyChina factory feature precise filling, consistent sealing, automated weight control, user-friendly interface, and high-speed operation. They ensure minimal waste and high efficiency in tea bag production.

Q2: What materials are used in the construction of these machines?

A2: The machines are constructed using high-quality stainless steel and food-grade materials to ensure durability, hygiene, and compliance with international safety standards.

Q3: Are your machines suitable for various types of tea?

A3: Yes, our tea bag packing machines are versatile and can handle different types of tea, including loose leaf, herbal, and granular tea. We offer customizable settings to cater to specific requirements.

Q4: How do you ensure the quality of your tea bag packing machines?

A4: Quality is assured through stringent quality control processes including precision machining, rigorous testing, and inspection at every production stage. We also adhere to ISO certification standards.

Q5: What is the production capacity of your tea bag packing machines?

A5: The production capacity varies by model. Generally, our machines can produce between 80 to 200 tea bags per minute, depending on the machine type and specific configurations.

Q6: Do you provide after-sales support?

A6: Yes, we offer comprehensive after-sales support including installation guidance, training, technical assistance, and maintenance services. Our dedicated support team is available to ensure smooth operation.

Q7: Can your machines be customized to meet specific needs?

A7: Indeed, we offer customization options to meet unique requirements such as varying tea bag sizes, shapes, branding through printing, and specific automation needs.

Q8: How energy-efficient are your tea bag packing machines?

A8: Our machines are designed to be energy-efficient, employing advanced technology to minimize power consumption while maintaining high operational efficiency and performance.

Q9: What is the lead time for machine delivery?

A9: The standard lead time for delivery is typically 4-6 weeks after order confirmation, depending on the machine specifications and customization requirements.

Q10: Do you offer warranties on your tea bag packing machines?

A10: Yes, we provide a standard warranty period of 12 months from the date of installation. Extended warranties and service contracts are also available upon request.