FAQs about Top and Bottom Labeling Machine Quality from SourcifyChina Factory

1. What types of products can the top and bottom labeling machine handle?

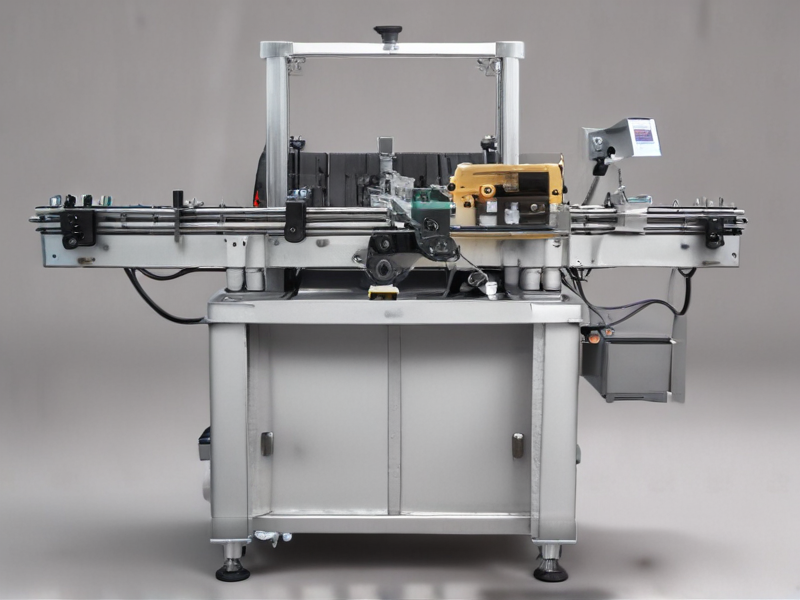

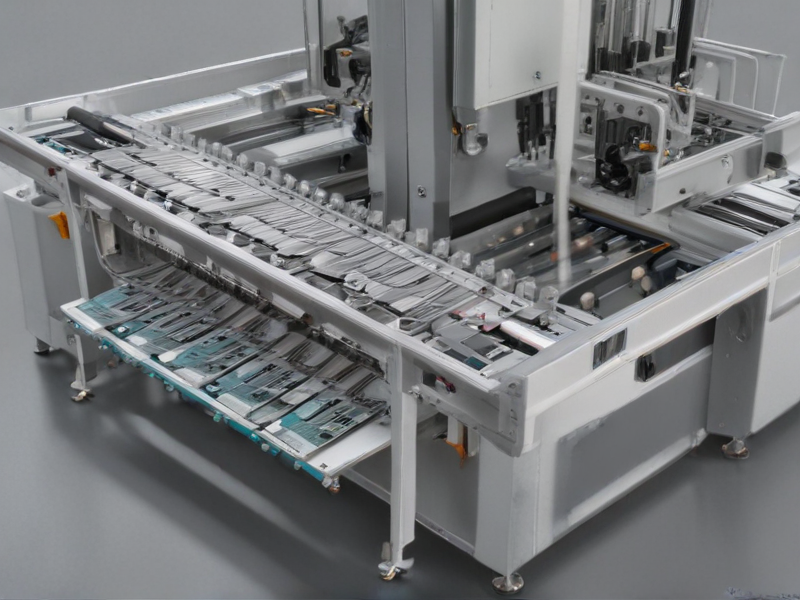

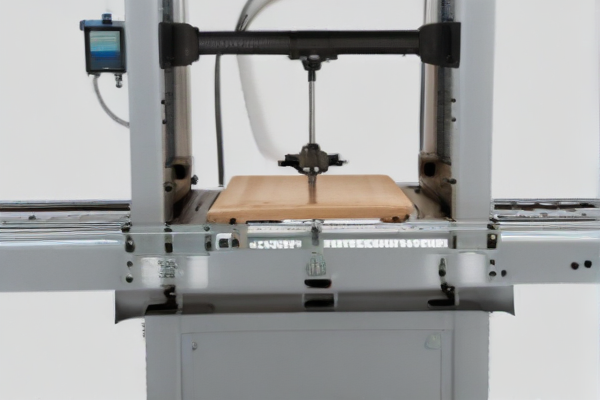

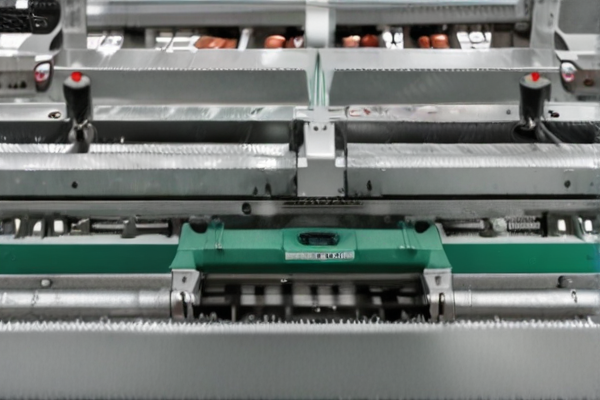

Our top and bottom labeling machines are versatile and can handle a wide range of products, including boxes, bottles, jars, and flat or slightly curved surfaces.

2. What are the quality standards followed by SourcifyChina Factory for manufacturing these machines?

We adhere to strict international quality standards, including ISO 9001, ensuring that each machine undergoes rigorous testing and quality checks before delivery.

3. How is the accuracy of labeling ensured?

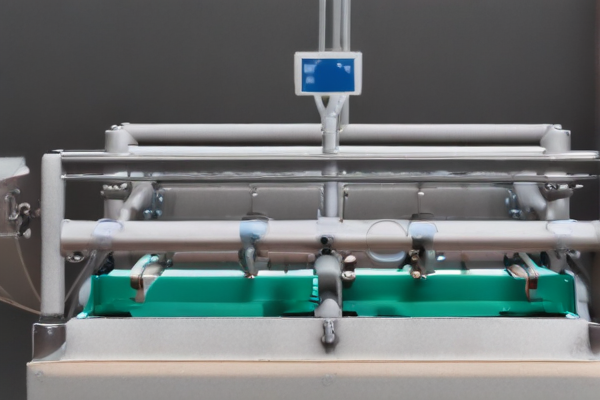

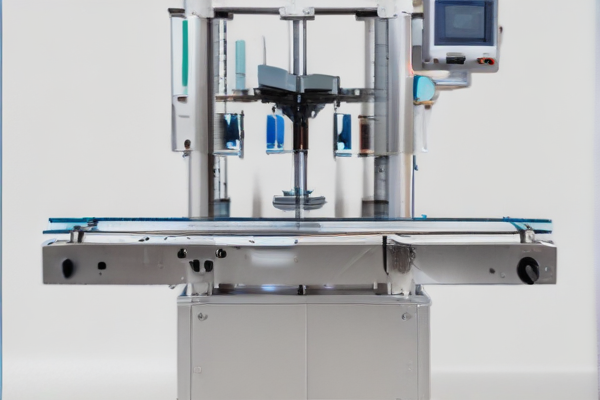

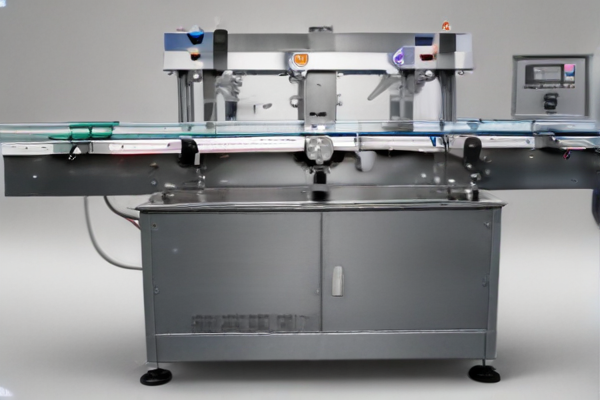

Our machines are equipped with advanced sensors and control systems to ensure precise alignment and placement of labels, maintaining high accuracy even at high speeds.

4. What materials are used in the construction of the labeling machines?

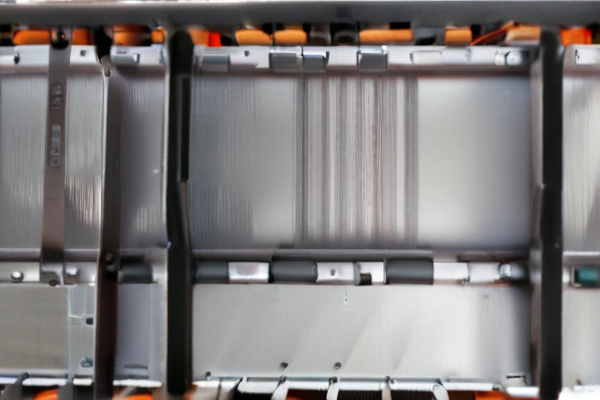

The machines are constructed using high-grade stainless steel and aluminum, which offer durability and resistance to corrosion, ensuring long-lasting performance.

5. Can these machines be customized according to specific requirements?

Yes, we offer customization options to meet specific needs, including modifications in size, speed, and labeling methods, ensuring the machine fits seamlessly into your production line.

6. What is the delivery time for a top and bottom labeling machine?

Delivery times vary depending on customization requirements but typically range from 4 to 8 weeks from the date of order confirmation.

7. Is training provided for operating the labeling machines?

Yes, we provide comprehensive training and detailed operation manuals to ensure your staff can effectively operate and maintain the machines.

8. What about after-sales support and maintenance services?

SourcifyChina offers robust after-sales support, including remote assistance, on-site service, and a supply of spare parts to ensure minimal downtime and continuous operation.

9. What are the energy consumption levels of these machines?

Our labeling machines are designed for energy efficiency, consuming minimal power while delivering high performance, which helps reduce operational costs.

10. How do I place an order or request a quote?

You can place an order or request a quote by contacting our sales team via email or phone, or by visiting our website to fill out the inquiry form.