Sure, here’s a list of frequently asked questions (FAQ) with answers regarding the quality and functionality of tray forming machines from SourcifyChina factory:

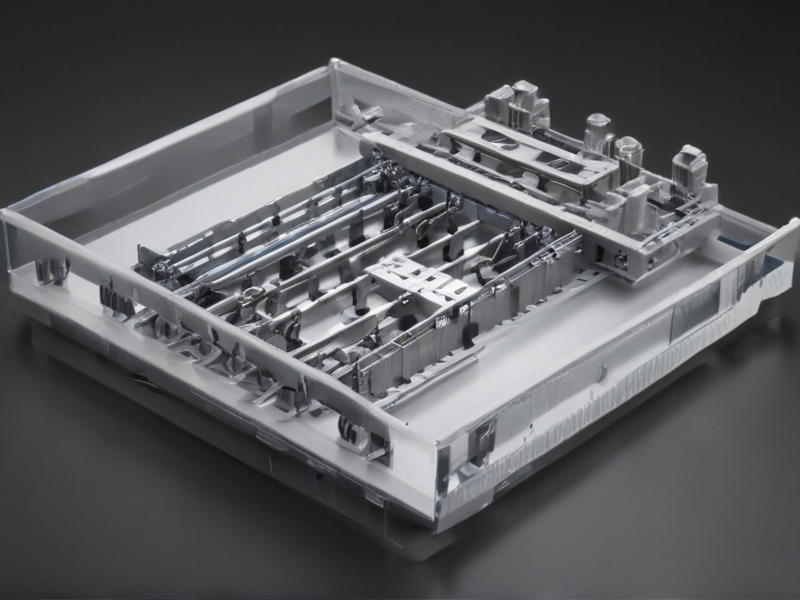

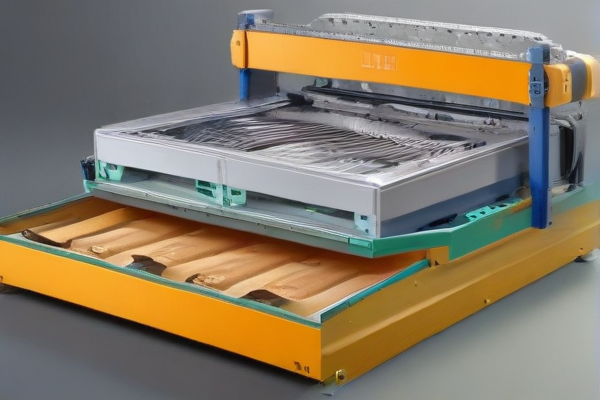

1. What is the production capacity of SourcifyChina’s tray forming machines?

SourcifyChina’s tray forming machines are designed for high efficiency and versatility, often handling up to 150 trays per minute, depending on the machine model and tray specifications.

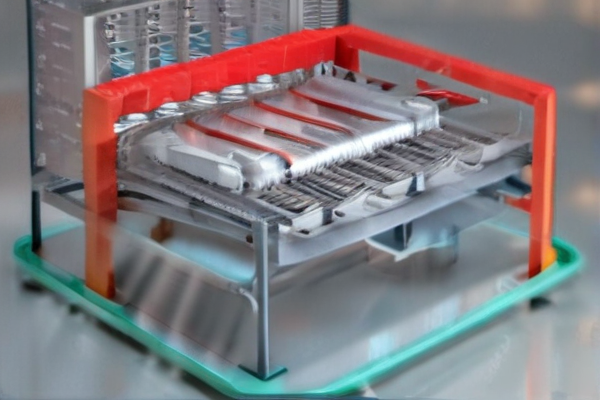

2. Are the tray forming machines customizable for different tray sizes?

Yes, SourcifyChina offers customizable solutions for various tray dimensions. The machines can be adjusted to form different sizes and shapes as per specific client requirements.

3. What quality certifications do SourcifyChina’s tray forming machines possess?

Our tray forming machines boast multiple quality certifications, including ISO 9001, CE marking, and other relevant international standards, ensuring top-notch manufacturing quality and safety.

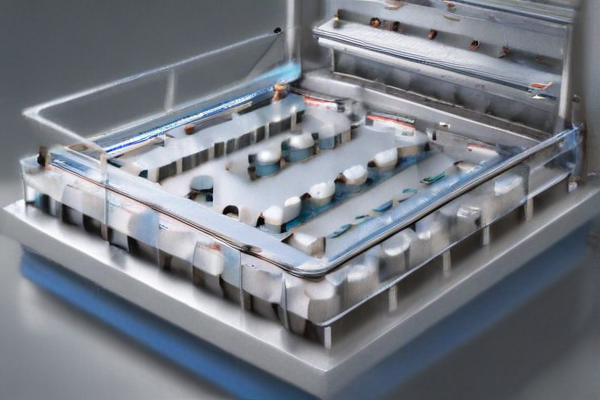

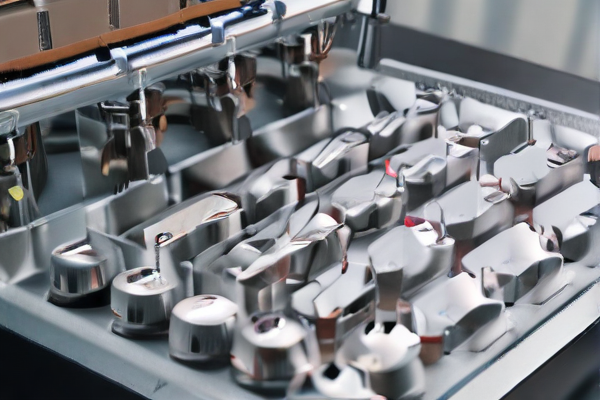

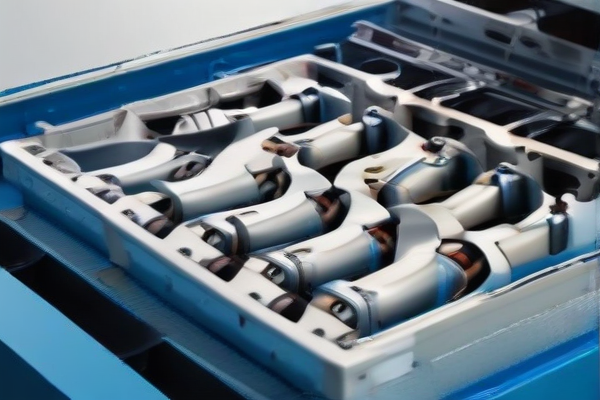

4. What kind of materials can these machines process?

SourcifyChina’s tray forming machines can handle a range of materials such as corrugated cardboard, solid board, and various eco-friendly substrates, providing flexibility in packaging options.

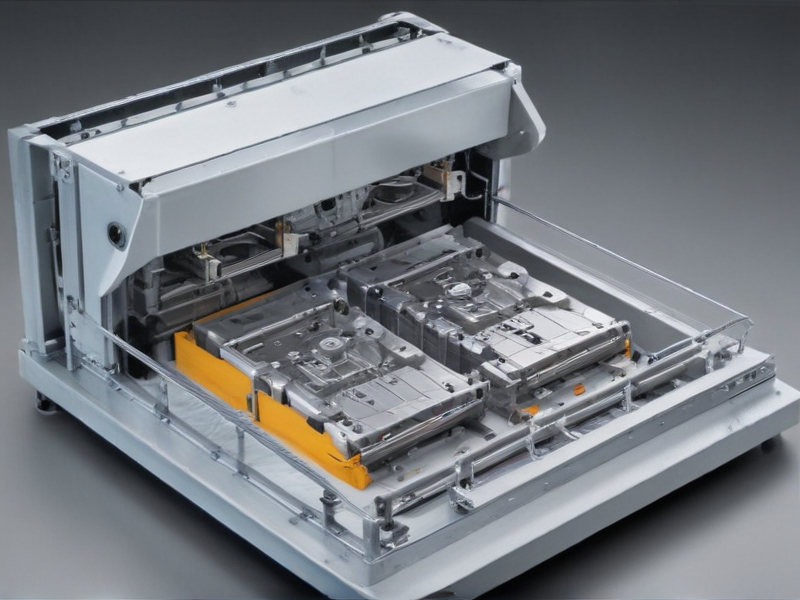

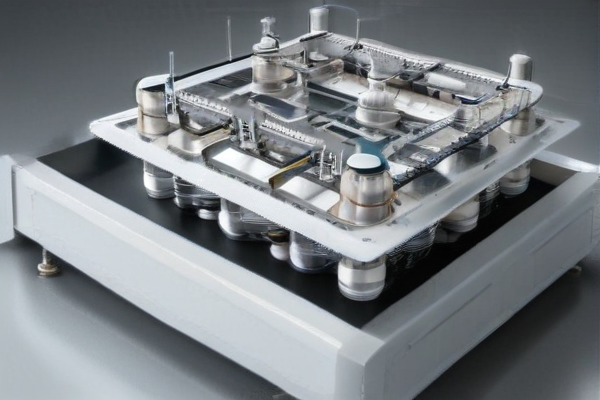

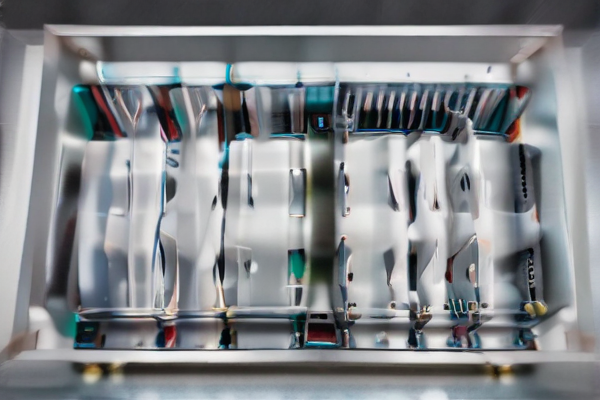

5. How is the machine’s performance monitored?

Our machines come equipped with advanced digital control systems and HMIs (Human-Machine Interfaces), enabling real-time monitoring and adjustments for optimal performance and reduced downtime.

6. Is there technical support available for troubleshooting?

Absolutely. SourcifyChina provides comprehensive technical support including remote troubleshooting, on-site service, and regular maintenance checkups to ensure smooth operation.

7. Do you offer training programs for operating the machines?

Yes, we offer extensive training programs for our clients’ operational teams to ensure they are well-versed in operating, maintaining, and troubleshooting the tray forming machines.

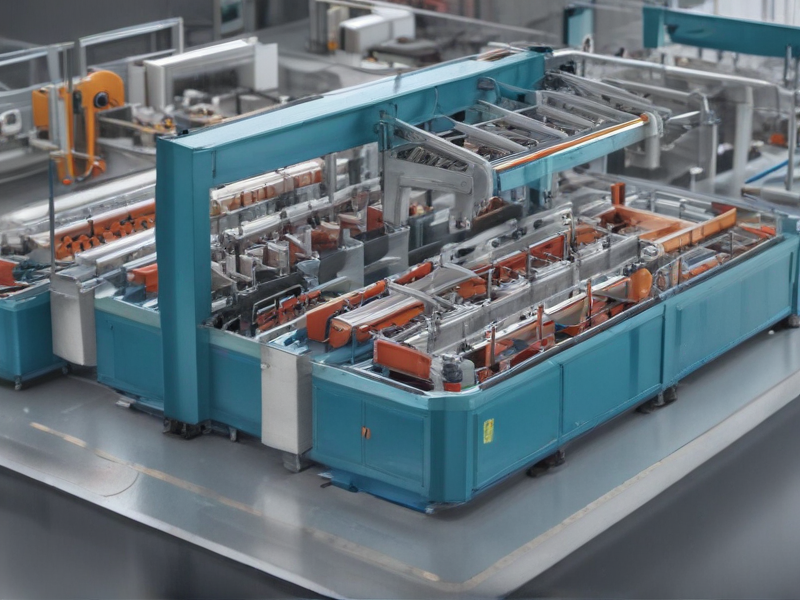

8. Can the machines be integrated into existing production lines?

Our tray forming machines are designed for seamless integration into existing production lines. We provide customization and engineering support to facilitate smooth integration.

9. What are the lead times for ordering and receiving a tray forming machine?

Lead times typically range from 6 to 12 weeks, depending on the level of customization and the current order backlog. We strive to deliver as promptly as possible.

10. What kind of warranty do you offer on the tray forming machines?

We offer a comprehensive one-year warranty on all parts and labor. Extended warranties and maintenance packages are also available upon request.