Q1: What types of vegetable packaging machines does SourcifyChina offer?

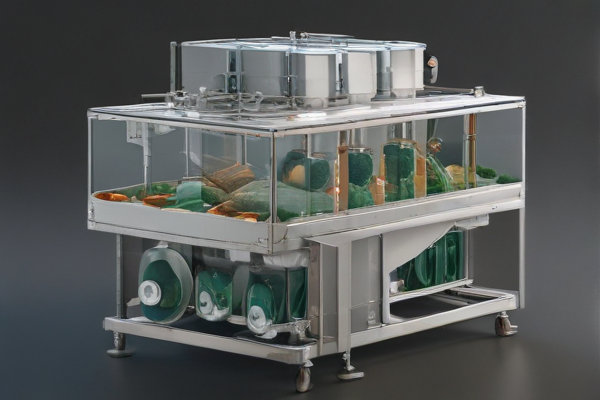

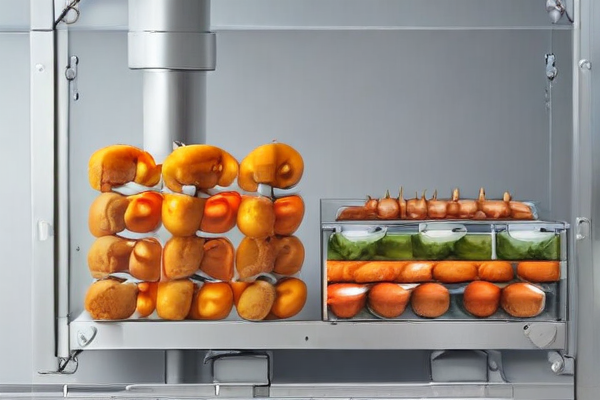

A1: SourcifyChina offers a variety of vegetable packaging machines, including vacuum packaging machines, pouch filling machines, and automatic weighers. These machines are designed to accommodate different types of vegetables, ranging from leafy greens to root vegetables.

Q2: Are the machines customizable?

A2: Yes, SourcifyChina provides customizable solutions to meet specific requirements. You can request modifications for size, capacity, and additional features to better suit your operational needs.

Q3: What materials are the machines compatible with?

A3: The machines can handle a range of materials such as plastic films, vacuum bags, and resealable pouches. This versatility ensures that the packaging needs of various types of vegetables are effectively met.

Q4: Do the machines comply with international standards?

A4: Yes, all machines manufactured by SourcifyChina comply with international standards like CE and ISO. This ensures reliability, safety, and high performance for global operations.

Q5: What are the payment terms?

A5: SourcifyChina typically offers flexible payment terms, including TT (Telegraphic Transfer), LC (Letter of Credit), and even PayPal for smaller orders. Specific terms can be discussed during the negotiation phase.

Q6: How long does it take to deliver the machines?

A6: Delivery timelines vary based on the complexity and customization required. Standard machines usually take 4-6 weeks, while customized solutions may take 8-12 weeks.

Q7: Do they offer installation and training services?

A7: Yes, SourcifyChina provides both installation and training services. Their team can install the machinery on-site and train your staff for optimal usage and maintenance.

Q8: What warranty and after-sales services are available?

A8: SourcifyChina offers a comprehensive warranty and reliable after-sales services, including regular maintenance and troubleshooting support. Warranty periods generally range from 1 to 2 years.

Q9: How can I get a quote?

A9: You can easily get a quote by visiting the SourcifyChina website and filling out the inquiry form. Alternatively, you can contact their sales team directly via email or phone.

Q10: What should I consider when choosing a vegetable packaging machine?